Robotics and Automation Consulting for Cannabis Producers

Sorting Robotics specializes in robotics consulting tailored specifically for cannabis producers. We work closely with you to understand your unique operations and craft automation solutions that improve consistency, increase output, and help you meet strict regulatory requirements. With our guidance, your business can run more smoothly, reduce reliance on labor, and be ready to grow as the market evolves.

Why Leading Cannabis Producers Are Turning to Automation

As the cannabis industry evolves, producers face growing challenges that demand more innovative solutions. According to a publication in Cannabis Science and Technology, for the cannabis industry, robots and other automation systems serve to lower costs, increase production, and build profitability early in the cannabis industry's growth, harvest, and logistics of delivering product to market. Here's what's driving the move to automation:

Labor Challenges in Cannabis Production

Labor shortages have left many roles unfilled, so an increasing number of growers rely on cannabis automation consulting to cut repetitive work and stabilize staffing. This reduces turnover and lowers operating costs.

Demand for Higher Throughput and Consistency

Additionally, cannabis robotics and pre-roll automation raise output while delivering uniform dosing and steadier product quality. That consistency strengthens brand trust.

Regulatory Compliance and Quality Control Needs

At the same time, regulatory compliance and quality control need automated workflows that simplify METRC reporting and make quality checks repeatable and auditable. These controls protect potency and terpene profiles.

Across leading factories in the World Economic Forum–McKinsey Global Lighthouse Network, AI and vision-enabled quality control have delivered two to three times productivity gains, up to a 99% reduction in defects, and about a 30% decrease in energy consumption. While these results come from broader manufacturing, they highlight the kind of step-change automation can bring to cannabis production.

Get Tailored Robotics Consultation That Works for Your Cannabis Business

At Sorting Robotics, we begin by thoroughly assessing your current production workflows to spot opportunities for improvement. This hands-on approach helps unlock greater efficiency, reduce waste, and deliver consistent product quality.

Continuous Performance Monitoring

Using real-time data, we help optimize yield and consistency, so your production continues to improve over time.

Our experts analyze every step of your process, from pre-roll automation to dosing, identifying bottlenecks and labor-heavy tasks.

Customized Workflow Assessment

Strategic Automation Planning

We develop clear, phased plans with detailed ROI forecasts to help you invest confidently in cannabis robotics that fit your goals.

Seamless Integration Support

Our team guides you through layout design and compliance-ready data integration, making sure new systems fit smoothly into your operation.

Training and Ongoing Support

With comprehensive training and proactive maintenance, we ensure your staff feel confident and downtime stays minimal.

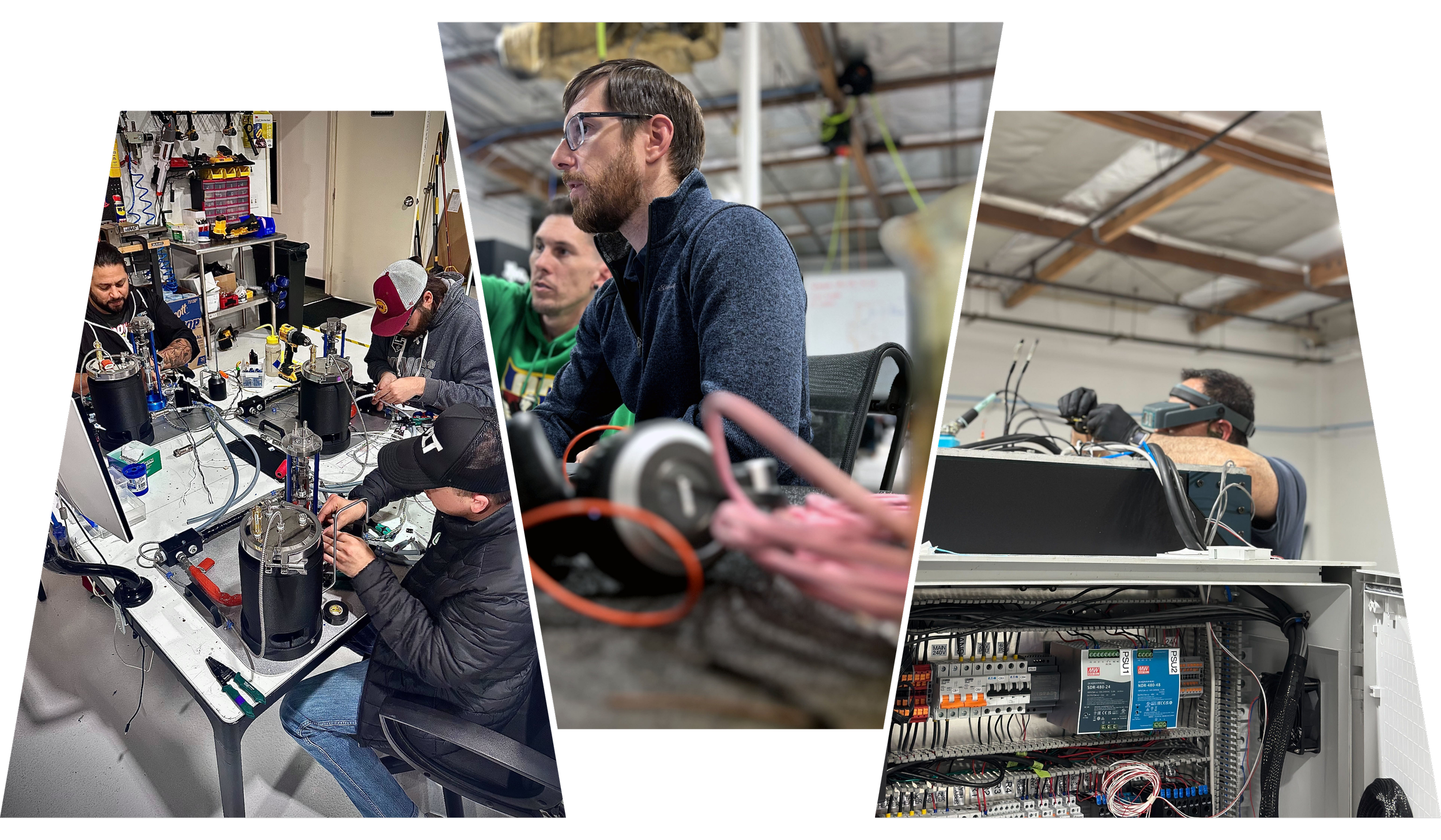

How We Craft Custom Automation Strategies That Deliver

Sorting Robotics' approach focuses on understanding your unique cannabis production challenges to design automation that truly fits your business. Every plan is built around real data and practical solutions that drive lasting improvements.

Custom Machines & Modifications

-

Our strategies prioritize flexibility, allowing your automation systems to grow with your business and adapt to changing market demands.

End-to-End Line Integration

-

We ensure your team is fully prepared with hands-on training and ongoing support, easing transitions and maximizing productivity from day one.

Product Development Work

-

We dive deep into your manufacturing processes, identifying inefficiencies and pinpointing where robotics and automation can have the most significant impact.

-

By analyzing costs and potential gains, we provide clear projections to help you make informed decisions about investing in cannabis automation.

Built With Experience.

Proven in the Field.

Nova Farms

"Expanded product line with minimal effort. Nova's infused preroll and blunt filling (infusion) is going very well.”

Rise Copacking

“Amongst everyone in the space, Sorting Robotics was by far the most data-driven team I’ve worked with. They didn’t just look at metrics — they understood them, analyzed them, and helped us build the right ones.”

Motiff Labs

“They helped us expand grow into the canadian infused pre-roll market and are always open to improvements."

Flow Distribution

“Sometimes the machine works so well it actually catches up to our pre-roll machine. Once we dialed in our process, it's been running smooth every day; it just fits right into the workflow.”

Delta Munchies

Check out our case study with Delta Munchies!

More Testimonials

Hear from other satisfied clients!

Ready to Build the Line You Actually Need?

Let’s talk about what’s slowing you down — and build the solution together.

We Serve All Booming Cannabis Industry Verticals in the U.S.

Sorting Robotics partners with cannabis producers across every significant segment of the industry, delivering automation consulting tailored to each unique operation. Our expertise ensures solutions that fit your specific production needs and challenges.

Infused Pre-Roll Manufacturing Facilities

We help optimize pre-roll production lines with robotics designed to enhance speed and consistency.

Concentrate and Extraction Producers

Our consulting supports automation that improves precision and quality in extraction and concentration workflows.

Packaging and Post-Processing Operations

From labeling to final packaging, we design systems that streamline processes and reduce errors.

Multi-State Operators (MSOs) and Craft Producers

Whether you manage multiple sites or focus on small-batch quality, our flexible strategies scale to your operation.

White-Label and Contract Manufacturing Facilities

We provide tailored automation plans that handle diverse SKUs efficiently, boosting throughput and maintaining compliance.

Food and Beverage

From packaging and sorting to portioning and hygiene compliance, our solutions improve safety and efficiency. Food and beverage companies can gain faster operations, reduced waste, and reliable adherence to quality standards.

Pharmaceuticals and Medical Devices

We assist with sterile handling, precise dosing, and full regulatory compliance. Sorting Robotics supports pharmaceutical and medical device manufacturers in achieving operational excellence while protecting product integrity and safety.

Logistics and Warehousing

Automated picking, packing, sorting, and inventory management reduce errors and speed up operations. Our consultation helps logistics and warehouse teams increase throughput while keeping processes organized and efficient.

Aerospace Industry

Complex assembly, detailed inspections, and safety-critical operations are simplified with our solutions. With our automation consultation, aerospace companies can benefit from higher consistency, improved quality control, and reliable production outcomes.

Healthcare and Laboratories

Medication dispensing, lab automation, and patient support are optimized through our robotics consultation. Sorting Robotics helps healthcare providers operate more efficiently while maintaining accuracy and safety in every process.

Agriculture and Horticulture

We improve planting, harvesting, sorting, and packing through automation. With our consultation services, agricultural and horticultural businesses gain higher productivity, reduced manual labor, and better-quality output, all while streamlining operations.

Energy and Utilities

Monitoring, inspection, and predictive maintenance are made more efficient with our solutions. Energy and utility companies reduce downtime, increase safety, and maintain equipment more effectively, enhancing overall operational performance.

Industries That Benefit from Our Robotics & Automation Consultation

Sorting Robotics' robotics and automation consultation delivers measurable efficiency, precision, and safety across multiple industries. Our team works closely with each client to tailor solutions that improve operations, reduce errors, and increase productivity.

Manufacturing Industry

We help manufacturers streamline assembly lines, enhance precision, and maintain consistent quality. Sorting Robotics provides tools and strategies that increase output while reducing costly mistakes, keeping your production competitive and reliable.

Automotive Production

Automotive production benefits from faster assembly, accurate part handling, and fewer defects. Our consultation optimizes workflow, helping manufacturers maintain high standards and meet tight production schedules with ease.

Electronics and Semiconductors

High-precision assembly, rigorous testing, and detailed inspection are critical in electronics and semiconductor manufacturing. Sorting Robotics ensures processes are accurate, efficient, and scalable, helping you maintain product reliability.

Automation Solutions We Recommend Based on Your Goals

Get Built-In Compliance and Quality in Every Solution

We know compliance and product quality are non-negotiable in cannabis production. That's why every automation strategy we develop is built to meet strict:

Alignment with State Cannabis Regulations and METRC Systems

Our automation strategies ensure smooth integration with regulatory tracking to keep your operation audit-ready.

Preservation of Potency and Terpene Profiles Through Automation

We prioritize technologies that protect the quality and consistency of your cannabis products at every step.

Scalable Solutions for Both Craft Producers and MSOs

Flexible designs grow with your business, whether you're a small craft producer or a large multi-state operator.

Optimized Automation for White-Label Manufacturing

Custom solutions help manage diverse product lines efficiently while maintaining strict quality standards.

Why Cannabis Producers Choose Sorting Robotics

Our team brings unmatched engineering skills rooted in NASA-grade innovation. This expertise ensures every automation solution is built with precision, reliability, and durability to meet the rigorous demands of cannabis production.

Proven Automation Systems Designed for Cannabis Production

We develop and recommend automation technologies specifically tailored for cannabis manufacturing. From pre-roll automation to dosing and packaging, our systems are tested to boost efficiency while maintaining product quality.

Real-Time Production Monitoring and Data Analytics

With real-time tracking, you gain clear visibility into every stage of your production line. Data insights help optimize yield, reduce waste, and maintain consistent product standards across batches.

Quick ROI and Dedicated Customer Support

Our solutions deliver quick returns on investment, often within the first year. Plus, we back every project with hands-on training and responsive support to keep your cannabis automation running smoothly and reliably.

Frequently Asked Questions

Through our consulting process, we pinpoint the best automation technologies to match your production goals and challenges. Whether you need to boost output, improve consistency, or streamline compliance, we recommend equipment that delivers real results.

Our precision-infused pre-roll systems, including Jiko and Jiko+, are designed to increase throughput while maintaining product quality. For enhanced coating accuracy, the Stardust kief machines offer advanced solutions tailored to your needs. We also advise on dosing and quality control technologies that ensure every batch meets strict standards.

Beyond production, we help implement packaging and post-processing automation to speed up finishing steps and reduce errors. For unique cannabis SKUs, custom robotics solutions provide flexibility and efficiency that standard systems can't match.

-

We provide consulting for infused pre-roll manufacturing, concentrate and extraction operations, packaging, post-processing, and custom robotics for unique cannabis products.

-

We conduct detailed workflow assessments and develop custom automation plans that align with your production goals, facility layout, and regulatory requirements.

-

Yes, our solutions include built-in compliance features and integrate with METRC systems to help maintain regulatory standards throughout your production process.

-

Many clients achieve a payback period within 12 months through increased throughput, labor savings, and reduced waste.

-

Absolutely. We offer hands-on operator training, ongoing technical support, and performance monitoring to ensure your automation runs smoothly.

-

Yes, our modular and scalable automation designs allow for flexible expansion to meet evolving production demands.

Future-Proof Your Cannabis Business with Expert Robotics Consulting

Ready to stay ahead in a fast-changing market? Our robotics consulting helps you build flexible, efficient production lines that grow with your business. Don't let labor shortages or compliance challenges hold you back. Connect with Sorting Robotics today to explore tailored automation strategies that boost output, ensure quality, and keep you competitive for years to come.

Get in touch now for a free workflow assessment and see how robotics can transform your cannabis production!

Check Out Our Robots

Jiko+

Go beyond the basics with Jiko+: automation that adapts to your growing business needs.

LAKA Production Data

Native Production Analytics software and Real Time Monitoring - included on all Sorting Robotics solutions.

Stardust

With Stardust, infuse, coat, and create premium products faster and more consistently.