Automation in Cannabis Manufacturing | An Overview

The cannabis industry has entered an era where hand assembly and manual processing just can’t keep up. To compete, especially under tight regulations and intense market pressure, brands are increasingly leveraging automation. We will walk you through how automation is transforming every step of cannabis production, including pre-roll infusion, where systems infuse pre-rolls with oil, rosin, and distillate, kief or concentrate coating, vape cartridge filling, and robotic packaging. You’ll see how each link in the chain can be optimized, and why getting the full system working together is the real game changer.

Beyond that, automation accelerates throughput, cuts labor costs, and helps you scale without exponentially increasing headcount. Perhaps most critically, automation supports compliance, traceability, and audit readiness, essentials in a highly regulated cannabis environment where maintaining accurate trace logs and process control is non-negotiable.

Numbers back the urgency: the North American cannabis technology sector is expected to reach 71 billion by 2030. That surge signals rapid industry adoption of sensors, robotics, smart fill systems, and integrated automation across cultivation, processing, and packaging.

In the sections ahead, we’ll break down each automation domain (infusion, coating, filling, packaging), outline key design and engineering challenges, and offer guidance on integration strategies. Let’s get started on building a leaner, more compliant, and truly scalable cannabis operation.

What Is Cannabis Manufacturing Automation?

Automation in cannabis manufacturing involves the strategic deployment of machines, robotics, sensors, and software systems to perform tasks that would otherwise be done manually. Rather than replacing human operators altogether, these technologies support labor by handling repetitive, tedious, or high-precision tasks, freeing humans to focus on supervision, quality control, R&D, and oversight.

By integrating robotics, AI, and automated systems, cannabis processors achieve greater precision, higher throughput, reduced waste, and improved consistency across batches. Robotic arms, computer vision, and AI algorithms can detect product defects, control dosing, adjust parameters mid-run, and manage cleaning cycles.

Modern systems can adapt on the fly; for example, vision systems can detect a misaligned cartridge and reject it before capping, or measure fill weights and provide real-time feedback adjustments. AI can also predict when machines will need maintenance, reducing downtime and preserving uptime for production, which is managed via monitoring optimization KPIs dashboards maintenance.

Key Types of Cannabis Automation

Cannabis automation isn’t a one-size-fits-all solution; it spans a variety of specialized machines, each designed to handle different stages of production. From pre-rolls to vape carts and packaging, these technologies work together to reduce manual labor, cut costs, and scale output efficiently. Below are some of the most impactful categories shaping today’s cannabis operations.

Pre-Roll Infusion Machines

Pre-roll automation goes far beyond rolling papers. These machines can dose precise amounts of cannabis, infuse oils or concentrates, tamp evenly, and seal pre-rolls in uniform batches. By removing variability in weight and infusion, brands can deliver consistent quality on a larger scale. Advanced infusion solutions like Industrial Moonglue showcase how robotics can handle high-volume infused pre-rolls with precision and minimal labor.

Kief and Concentrate Coating Systems

Instead of relying on manual dusting or dipping, coating machines apply kief or liquid concentrates in a controlled, uniform layer. This ensures that every product looks and performs the same, while also reducing material waste. As brands compete for eye-catching infused products, automated coating delivers both efficiency and aesthetics.

Vape Cartridge Filling Systems

Vape cartridges demand precision; even a slight dosing error can ruin the experience or waste valuable oil. Automated fillers handle hundreds to thousands of cartridges per hour with exact dosing accuracy, while minimizing operator exposure to sticky concentrates. Advanced systems can also integrate capping, further streamlining production.

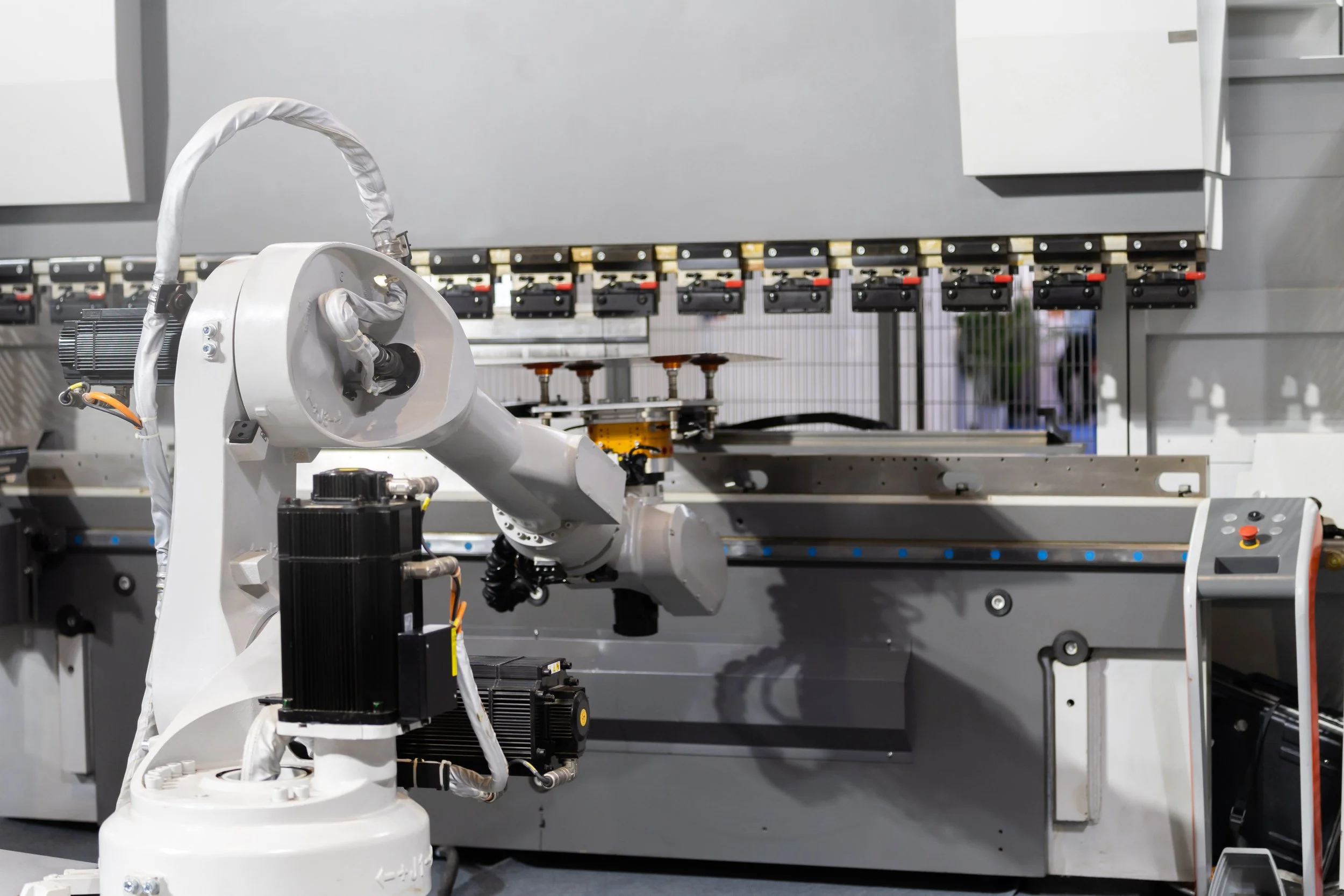

Robotic Packaging Solutions

Packaging is one of the most labor-intensive areas of cannabis production. Robotic arms and pick-and-place systems, such as pick and pack robots speed cannabis packaging, can quickly sort, pack, and seal products into cartons, bags, or display units. By automating packaging, companies cut labor costs, a major benefit achieved because robots reduce human labor costs significantly. The automation helps reduce errors and maintain consistent presentation on store shelves.

Trimming and Sorting Robotics

Robotics equipped with vision systems and AI is revolutionizing flower handling. These machines can remarkably accurately trim buds, identify defects, and sort by size, quality, or density. This reduces the burden on manual trimmers and ensures compliance with quality standards while increasing throughput.

Why Automation Matters in Cannabis Production

When you dig deeper into modern cannabis operations, automation isn’t just a flashy add-on, it's often the difference between sustainable scale and chaotic bottlenecks. Below are the core levers where automation drives value:

Efficiency & Throughput

Automated systems vastly accelerate repetitive tasks. What once required dozens of workers and multiple manual steps can now be compressed into minutes or even seconds per unit, from filling cartridges to final packaging. A strong example comes from Nature’s Grace and Wellness (NGW). The company used to produce about 5,000 pre-rolls per week with nine operators. After introducing the automated system, they now generate 13,000 to 16,000 pre-rolls per day, nearly 100,000 per week, with only two operators.

Lower Labor & Operational Costs

Labor is one of the most significant cost centres in cannabis manufacturing. By shifting high-touch, tedious tasks to machines, businesses can reduce headcount, minimize overtime, and redeploy staff to higher-value roles (quality control, monitoring, maintenance). As MG Magazine notes, automation helps cut labor costs, improve consistency, and boost margins, making it a competitive differentiator in a crowded market.

Consistent Dosing & Quality Control

Consistency is non-negotiable: every unit must meet potency, weight, and purity standards. Automated dosing, vision inspection, and feedback loops help ensure that variance stays within tight tolerances. Advanced AI-backed grading and vision systems can flag defects or subpar units before they leave the line, reducing rejects and brand risk.

Regulatory Compliance & Traceability

Cannabis is among the most regulated industries. Automation helps build audit trails, timestamped logs, and integrated batch-level data. Packaging robots, for instance, can embed serialized labels and maintain chain-of-custody records with zero manual transcription. Automated systems in packaging also reduce the time and error risk inherent in manual operations.

History and Evolution of Cannabis Automation

In the early days of cannabis manufacturing, everything was done by hand: pre-rolls were rolled manually, infusions were done with rudimentary tools, and packaging was labor-intensive. As cannabis legalization spread, demand grew for consistent quality, higher throughput, and tighter compliance, triggering the move toward semi-automated tools. These included machines to assist in filling, trimming, and basic packaging, but human hands still handled much of the critical finishing work.

Starting around 2020, systems evolved toward more complete automation. Robotics, AI vision systems, and specialized infusion or coating tools began emerging to handle formerly manual bottlenecks. One notable milestone was when engineered systems first enabled infused pre-roll automation, the ability to dose, infuse, and finish pre-rolls at scale with minimal manual intervention.

Alongside this technical evolution, the market data also began reflecting the accelerating adoption of technology across the cannabis production chain:

The global cannabis technology market was valued at USD 6.2 billion in 2024 and is projected to grow to USD 23.7 billion by 2030, exhibiting a compound annual growth rate (CAGR) of about 24.9% over that period.

On the adoption side, more than 80% of cannabis cultivators were using automation for packaging and trimming by 2024, up from about 10% in 2021.

These numbers show that automation is not just a technical novelty, it's increasingly seen as essential infrastructure in cannabis operations. The evolution has gone from manual → semi-automated → fully automated systems, especially in stages that historically suffered from variability or labor constraints.

Core Applications of Cannabis Automation

Automation in cannabis isn’t just about reducing labor, it’s about precision, compliance, and scalability. From pre-rolls to vape cartridges, machines are being engineered to handle tasks once performed by dozens of operators. Each system targets a unique production bottleneck, unlocking efficiency at scale.

Pre-Roll Infusion Systems

Infused pre-rolls are among the fastest-growing product categories in legal cannabis markets. Automated infusion systems allow manufacturers to dose flower with oils, rosin, or even create hash holes with consistency impossible by hand.

These machines can process 1,000–1,200 infused joints per hour, ensuring each unit is uniform in potency and burn quality. This level of output gives operators the flexibility to meet high demand while maintaining product quality and compliance standards.

Kief Coating Machines

Kief Coated pre-rolls are notoriously labor-intensive when produced manually, as hand-rolling in kief can lead to uneven coverage and wasted material. Automated kief coating systems such as Stardust simplify the process, rolling each joint uniformly for a clean finish.

The result is significant labor savings and product consistency across batches, allowing manufacturers to scale up production without sacrificing quality. Automation also helps reduce raw material waste, an important factor in keeping margins healthy.

Vape Cartridge Filling

Vape cartridges remain a cornerstone of cannabis retail sales, and filling them accurately is critical for both compliance and consumer trust. Cartridge fillers like Omni offer desktop-sized automation that ensures precise dosing down to microliter levels.

These systems are engineered to handle multiple viscosities, from thin distillates to thick live resin extracts, while minimizing spillage and waste. By improving throughput and lowering material loss, automated fillers maximize yield while delivering reliable products to market.

Pick and Pack Robotics

Packaging is often overlooked but represents one of the most labor-heavy aspects of cannabis production. Robotic arms, such as those used in the Mayweather system, streamline the pick-and-pack process for cannabis SKUs, speeding up order assembly while reducing the margin of human error.

These robots can sort, label, and package products with consistency that meets both retail and compliance requirements. Beyond labor reduction, automated packaging ensures faster turnaround and a smoother supply chain for large-scale operators.

ROI and Business Impact of Automation

For cannabis operators, automation isn’t just about keeping up with the latest technology, it’s about making the numbers work. The return on investment (ROI) shows up quickly when you factor in lower labor costs, reduced waste, and more consistent product quality.

One of the biggest expenses in cannabis production is labor. Manual pre-roll lines, for example, often require five to ten employees working long shifts, yet output remains limited. With automation, the math looks very different. A case study showed production rising from 2,500 pre-rolls per shift with four workers to 8,000 with just one operator, cutting labor costs by nearly 75%. This kind of efficiency turns payroll savings directly into margin gains.

Waste reduction is another area where ROI becomes clear. Inconsistent dosing or uneven packing often leads to rejected units and wasted material. According to Benzinga, the labor and material cost per infused pre-roll can drop from about US$0.30 per unit manually to as little as US$0.04 with automation when operating at scale. Multiply that savings across tens of thousands of units per month, and the impact is dramatic.

To put it into perspective: a facility rolling 1,000 joints a day by hand might spend around US$1 per unit after labor and waste. The same operation could produce 3,000 joints a day at about US$0.07 per unit by switching to automation. That’s nearly US$20,000 in monthly savings, meaning machines often pay for themselves within months rather than years.

Industry-wide data backs this up. Research shows that digital automation in cannabis has cut labor costs by around 20% while increasing operational efficiency by nearly 30%. For operators juggling tight margins and compliance-heavy workflows, those percentages are often the difference between breaking even and scaling profitably.

Automation is not just about convenience, it’s a bottom-line growth engine. By improving throughput, reducing waste, and ensuring compliance, the business case for automation in cannabis is stronger than ever.

Challenges in Adopting Automation

While automation delivers clear ROI, transitioning isn’t without hurdles. Many cannabis operators find that the initial adoption phase requires careful planning and investment. Understanding the key challenges up front, and knowing how to overcome them, can make the difference between a smooth rollout and costly setbacks.

Upfront Investment

High-quality cannabis automation equipment often comes with a significant price tag. Pre-roll infusion systems, vape fillers, and robotic arms can run into tens or even hundreds of thousands of dollars. For smaller businesses, this can feel daunting. The best practice is to evaluate ROI timelines, often measured in months rather than years, and consider leasing or financing options that spread costs over time as production ramps up.

For operators navigating the adoption phase, robotics consulting services can help assess ROI, plan integration, and reduce risk during implementation.

Staff Training

Even the most advanced equipment still requires trained operators. Staff need to understand how to set up, monitor, and troubleshoot systems. Without proper training, automation can underperform or cause bottlenecks. A practical approach is to work directly with manufacturers who provide onboarding and certification programs, ensuring employees gain confidence before equipment goes fully live.

Facility Setup

Automation often requires adjustments to the production floor. Machines may need dedicated space, reliable power supplies, or environmental controls to perform optimally. Planning for layout changes in advance, such as allocating square footage, ensuring ventilation, and upgrading electrical infrastructure, reduces downtime and avoids last-minute surprises.

Machine Maintenance

Automated systems are built for durability, but they still require regular upkeep. Neglecting maintenance can lead to breakdowns that halt production. Operators should adopt preventive maintenance schedules, stock essential spare parts, and train staff on basic servicing. Partnering with vendors that offer strong after-sales support also helps minimize risk.

Design Principles for Effective Automation

Not all automation is created equal. The most successful cannabis systems are those designed with precision, safety, and scalability in mind. When evaluating equipment, operators should look beyond output numbers and focus on whether the design supports long-term efficiency, compliance, and growth.

Precision and Consistency

Accuracy is at the heart of cannabis automation. From pre-roll infusion to vape cartridge filling, even small dosing errors can cause compliance issues or dissatisfied customers. Automated systems should deliver repeatable quality, ensuring each unit matches potency and weight specifications. Precision reduces variation, minimizes waste, and ultimately strengthens consumer trust in a brand’s products.

Safety and Compliance Design

Cannabis manufacturing operates under strict standards, so automation must align with both Good Manufacturing Practices (GMP) and OSHA guidelines. Machines should be built with materials and finishes that support easy cleaning to prevent contamination. Features such as interlocks, emergency shut-offs, and proper guarding ensure worker safety. A compliance-focused design not only protects employees but also shields businesses from costly recalls or regulatory penalties.

Scalability in Design

An effective system should grow with the business. Modular automation platforms allow operators to expand output without replacing existing equipment; for example, by adding new lanes, cartridges, or robotic arms as demand increases.

This scalability means that companies don’t have to overinvest early but can scale production steadily in line with market demand. Custom robotics manufacturing services also enable operators to build tailored systems that align with their production needs.

Materials and Durability of Automation Systems

Choosing the right materials in cannabis robotics isn’t just about longevity, it's about product safety, cleanability, and maintaining dosing accuracy. Here’s a breakdown of what makes automation hardware durable and reliable.

Stainless Steel Components

Stainless steel is the backbone of many food-grade and cannabis automation systems. It is:

Durable & Corrosion-Resistant: Grades like 304 and 316 stainless steel resist rust, oxidation, and damage even when exposed to acidic extracts, oils, moisture, or cleaning chemicals. That means less material fatigue and fewer component failures.

Cleanable & Hygienic: Its smooth, non-porous surface doesn’t trap residues, and withstands rigorous washdowns or sterilization, which helps prevent microbial contamination. According to industry sources, 304 stainless steel offers superior corrosion resistance and supports frequent sanitation without structural degradation.

Strength & Longevity: Stainless steel can endure mechanical stress, vibration, frequent cleaning, and even temperature swings better than many metals or lesser alloys. Its extended lifespan lowers replacement costs and downtime.

High-Grade Plastics and Seals

When handling oils, resins, extracts, or sticky concentrates, metal isn’t always enough, seals, gaskets, or some non-structural components must be plastic or polymeric. Key considerations are:

Chemical Compatibility: Plastics and elastomers must resist degradation, swelling, or leaching when in contact with cannabis oils, solvents, or cleaning agents. FDA-approved plastics (e.g., PTFE, HDPE, food-grade silicone) are often used to ensure safety.

Seal Integrity: Proper seals prevent leaks, maintain vacuum or pressure where needed, and avoid contamination. High-grade sealing materials ensure that dosing accuracy isn’t compromised by small leaks or material bleed.

Temperature Stability: Extracts can be heat-sensitive, and plastics and seals that degrade or deform with heat will compromise system performance. Good plastics retain shape under low and moderate heat and resist swelling in vapor or solvents.

Electronics and Heat Control Systems

Sensors, heat control, and electronic components are just as critical:

Accurate Temperature/Fan/Heat Control: Many cannabis extracts or infusions require precise temperature regulation. Too much heat can degrade cannabinoids or terpenes, too little might lead to incomplete infusion or curing. Good control systems keep processes within tight ranges.

Sensors & Feedback Loops: Weighing sensors, flow sensors, and thermocouples provide real-time monitoring. Feedback loops allow the system to self-correct, for example, adjusting dosage if flow slows or viscosity changes.

Reliability under Harsh Conditions: Electronics need to survive humidity, sticky vapors, mechanical vibration, and cleaning cycles. Designing for ingress protection, sealed electronics, and components rated for industrial duty helps maintain performance over time.

Installation and Setup of Cannabis Automation

Bringing automation into a cannabis facility isn’t just about unpacking a machine and turning it on. Successful adoption depends on preparing the right environment, following a careful setup process, and ensuring operators are trained. With proper planning, facilities can avoid costly mistakes and maximize uptime from day one.

Tools and Facility Requirements

Automation equipment often requires specific infrastructure before installation begins. Facilities should ensure:

Space: Dedicated floor area with clearance for safe operation and maintenance. Sufficient space also allows for smooth product flow and compliance inspections without disruption.

Power: Adequate electrical supply, often with dedicated circuits or higher voltage for industrial machinery (NFPA electrical standards). Many cannabis facilities also install surge protection and backup systems to avoid downtime from power fluctuations.

Ventilation: Proper airflow and extraction to maintain worker safety and product quality. Good ventilation also reduces dust buildup, which can affect both equipment performance and cleanroom compliance.

Tools & Consumables: Setup tools (wrenches, calibration weights) and compatible production inputs such as cones, cartridges, or seals. Keeping spares on hand ensures that calibration or testing isn’t delayed during installation.

Having these requirements ready reduces delays once the equipment arrives.

Step-by-Step Setup Process of Installation Process

The general setup process typically includes:

Delivery & Unpacking: Machines arrive in protective crates; careful handling prevents damage. Teams should check all components against the packing list to ensure nothing is missing before installation begins.

Positioning & Connections: Units are positioned and connected to power, ventilation, and software. Proper placement is critical for workflow efficiency and to minimize unnecessary operator movement during production.

Calibration: Fine-tuning dosing and alignment ensures compliance with GMP principles. Calibration should be repeated periodically, as temperature and material viscosity can cause shifts in dosing accuracy over time.

Test Runs: Pilot batches confirm throughput, dosing precision, and system stability. Running multiple test cycles also helps identify small inefficiencies that could become costly at full scale.

Operator Training: Staff are trained to run, clean, and troubleshoot equipment for consistent results. Well-trained operators can spot early signs of wear or misalignment, preventing downtime and reducing repair costs.

Common Setup Mistakes to Avoid

Even advanced machines can underperform if not installed or configured properly. Some of the most common mistakes include:

Poor positioning of feeders, sensors, or robotic arms often causes jams and rejected products. This misalignment is easy to overlook but can slow down the entire production line and reduce overall efficiency.

Failing to adjust temperature and pressure settings for different cannabis oil viscosities leads to inaccurate dosing and wasted material. Since extracts vary from thin distillates to thick rosins, fine-tuning viscosity settings is essential for smooth flow and consistent results.

Neglecting regular calibration results in inconsistent fill weights, dosage errors, and compliance risks. Skipping this step affects product quality and increases waste, as out-of-spec units cannot be sold.

Inadequate operator training often results in machines running less than full efficiency. Operators who don’t understand system functions are likelier to make mistakes, miss warning signs, or perform cleaning and maintenance incorrectly.

Ignoring preventive maintenance schedules can shorten the lifespan of expensive equipment. Simple tasks like lubrication, sensor cleaning, and part replacement may lead to breakdowns and costly downtime if overlooked.

Attention to these details prevents recurring quality problems.

Professional Installation Benefits

Although some teams attempt an in-house setup, professional installation provides clear benefits. Certified technicians ensure optimal alignment, validate warranties, and accelerate operator training. Industry case studies show that a professional setup helps equipment reach rated throughput faster, leading to higher ROI.

Professional installers also provide valuable insights on facility layout and workflow optimization that can improve efficiency beyond the machine itself.

Maintenance and Care for Cannabis Robots

Like any precision equipment, cannabis automation systems require regular maintenance to perform at their best. Developing a structured care plan, covering daily, weekly, and seasonal routines, ensures uptime, extends machine life, and keeps production compliant with regulations. Preventive care not only reduces downtime but also helps operators avoid costly emergency repairs.

Cleaning and Sanitizing Machines

Daily cleaning is essential, especially in cannabis facilities where oils, kief, or dust can quickly accumulate. Operators should:

Power down and unplug machines before cleaning.

Use manufacturer-approved cleaning agents to avoid corrosion or damage.

Wipe down stainless steel surfaces with food-safe sanitizers for GMP compliance.

Clean dosing nozzles, trays, and moving parts carefully to prevent buildup that can affect accuracy.

Deep cleaning should be scheduled weekly, including disassembly of parts like hoppers or cartridges. Regular sanitization protects product integrity and keeps equipment running smoothly.

Replacing Parts and Consumables

Some components wear out faster than others and should be monitored closely. Needles, gaskets, and filters are consumables that often require replacement after a set number of operating hours. Neglecting these replacements can lead to dosing inconsistencies, leaks, or contamination.

Maintaining an inventory of spare parts reduces downtime, ensuring machines return to operation quickly when replacements are needed. Manufacturers often provide recommended replacement intervals, and sticking to these guidelines can extend overall machine life.

Software Updates and Calibration

Automation isn’t just mechanical, it relies on software and sensors for accuracy. Keeping firmware up to date ensures machines benefit from the latest features, security patches, and performance improvements. Operators should also recalibrate dosing and alignment at scheduled intervals, especially when switching between product types.

Skipping calibration or running outdated software can lead to compliance risks and lost productivity. A routine that combines software updates, firmware checks, and calibration cycles is critical for long-term efficiency.

The Psychology of Automation in Cannabis

Automation in cannabis manufacturing isn’t just about efficiency and compliance, it also shapes how consumers and partners perceive a brand. In an industry where professionalism and trust are still being established, the way products are made can send powerful signals about quality and innovation.

From a consumer’s point of view, automation communicates professionalism. When dosing is precise, packaging is uniform, and product quality is consistent, customers feel they’re buying from a reliable brand.

Automation also strengthens consistency, which is highly valued. People want the next product they buy to feel the same as the last, same potency, same experience. Trust in quality is increasingly a deciding factor: according to a 2023 Edelman study, 88% of adult consumers globally say trust in brands is an important consideration when they make purchases.

Lastly, automation projects an image of innovation. It tells customers, investors, and regulators that a brand isn’t just keeping up, but pushing forward. Brands that adopt robotics and smart systems are seen as forward-thinking, scalable, and better prepared for long-term growth.

Regulations and Compliance for Automated Systems

By designing equipment around regulatory frameworks, producers reduce risks of fines, recalls, or product failures that could damage brand reputation.

Minimum Quality and Safety Standards

Automated systems must adhere to baseline standards for materials, construction, and safety. For example, Good Manufacturing Practices (GMP) outline procedures for cleanliness, documentation, and quality control in cannabis facilities (FDA GMP Overview). Likewise, OSHA regulations ensure that workers are protected from hazards such as high-voltage machinery, heat exposure, or repetitive strain injuries (OSHA Safety Standards).

Data Tracking for Compliance

One of automation’s biggest advantages is its ability to support audit-ready reporting. Machines equipped with sensors and software can log production data in real time, from batch weights to temperature records. This digital trail helps companies demonstrate compliance during inspections, while also reducing human error in record-keeping.

According to Deloitte, data automation can cut compliance reporting costs by up to 30% in highly regulated industries (Deloitte Compliance Report). For cannabis, where every milligram must be accounted for, this kind of traceability is essential.

Cannabis-Specific Regulations

Cannabis compliance isn’t one-size-fits-all. States impose unique rules on pre-rolls, concentrates, and vape products, from maximum potency levels to labeling and packaging requirements. For instance, California requires child-resistant, tamper-evident packaging for pre-rolls, while Colorado enforces strict dosing limits on edibles and infused products (NCSL Cannabis Laws).

Automation systems can be calibrated to meet these varying requirements, ensuring dosing accuracy and packaging consistency no matter the jurisdiction. By doing so, brands can scale into new markets without overhauling entire production lines.

Trends and Innovations in Cannabis Automation

As regulatory pressures increase and consumer expectations rise, innovations are emerging that push the boundaries of what robotics, AI, and smart systems can do. Below are some of the latest trends shaping the future:

AI, IoT, and Predictive Process Control: More cannabis manufacturers are using IoT sensors and AI to monitor extraction workflows, grow-room environments, and finishing processes. These systems allow real-time adjustments for temperature, humidity, and flow rates, reducing waste and improving product consistency.

Robotic Packaging Arms & Vision Systems: Packaging is undergoing a transformation. Automated arms equipped with computer vision are now capable of sorting, filling, sealing, and labeling with high precision.

Advanced Pre-Roll Infusion & Coating Robots: Innovations like Stardust (kief coating) and Jiko/Jiko+ (infusion) show how formerly manual, tedious tasks are being systematized.

Blockchain & Supply Chain Transparency: Traceability is a growing concern: from seed to sale, regulatory bodies and consumers want to know exactly what’s in products and how they were made.

Modular Systems and Flexible Automation for Small-Batch Producers: Not all innovations are for big-industry players. There’s a rise in modular automation platforms that allow smaller producers to scale up without huge upfront investments.

Cannabis Automation and Business Growth

For cannabis companies, automation is more than a tool for efficiency, it’s a growth enabler. By streamlining repetitive and labor-intensive processes, automation allows brands to scale production volumes without proportional increases in labor costs.

Automation also plays a crucial role in expanding product lines. From infused pre-rolls to vape cartridges and kief-coated products, automated systems provide the flexibility to introduce new SKUs without drastically overhauling operations. Modular and programmable equipment lets manufacturers switch between product types quickly, enabling brands to stay agile and respond to evolving consumer preferences.

Perhaps most importantly, automation supports entry into new markets. With precise dosing, reliable compliance reporting, and consistent quality, automated production gives businesses the credibility regulators demand and consumers trust.

Global Perspectives on Cannabis Automation

Below is a overlook at how these differences are unfolding.

North America’s Market Leadership

In the U.S. and Canada, automation adoption is advancing quickly. North America currently accounts for over 62% of the cannabis technology market revenue globally. Canada specifically is expected to increase its cannabis tech market from around USD 299.1 million in 2023 to USD 1,546.6 million by 2030, a CAGR of ~26.5%.

These figures are driven by fully legalized frameworks in Canada and a patchwork but expanding legal market in many U.S. states, strong regulatory requirements, and high investment in cultivation, processing, compliance, and packaging automation.

Europe and Compliance Standards

Europe has different incentives for automation: regulatory compliance (especially for medical cannabis), GMP and EU-GMP certifications, and stricter safety / quality standards are pushing innovation. In another case, North Macedonia’s Pharmarolly installed a CO₂ extraction system under EU-GMP standards.

These kinds of regulatory requirements (cleanability, documentation, process control) mean that automated and highly controlled systems are almost required for operators who want access to EU medical cannabis markets.

Emerging Markets in LATAM and Asia

Adoption in Latin America and Asia is growing, though often from a lower base, and frequently focused first on medical cannabis or specifically regulated extracts. The LATAM cannabis market is expected to reach USD 4.72 billion in 2025, with a CAGR of about 4.18% through 2030.

For testing automation globally, North America leads in share, Europe is significant, and Asia-Pacific is showing some of the fastest growth rates in recent forecasts. In many LATAM countries, regulatory clarity is advancing, which opens opportunities for more sophisticated automation.

From Manual to Modern: Start Your Automation Journey

Automation has become a cornerstone of modern cannabis manufacturing, transforming how pre-rolls, vape cartridges, and infused products are produced. From efficiency gains and labor savings to improved dosing accuracy and compliance tracking, robotics and automated systems are reshaping the industry’s future.

If you’re ready to explore what automation can do for your cannabis business, now is the time to take the next step. Sorting Robotics offers cutting-edge solutions designed to boost efficiency, ensure compliance, and help brands scale production without sacrificing quality.

Book a demo with Sorting Robotics today and see firsthand how intelligent automation can transform your operations.

Frequently Asked Questions

What ROI can cannabis automation deliver?

Cannabis automation often delivers strong returns by reducing labor costs, increasing throughput, and minimizing waste. According to Deloitte, automation in regulated industries can cut compliance and reporting costs by up to 30%, further adding to ROI. Many cannabis businesses report payback periods of 12–24 months for major automation investments.

How hard is it to train operators?

Most modern cannabis automation systems are designed with user-friendly touchscreens, pre-programmed workflows, and simple calibration steps. Training often takes only a few days, with vendors typically offering on-site support, manuals, and digital resources.

Do automated systems meet compliance?

Yes. Automation is built around Good Manufacturing Practices (GMP) and often designed to align with FDA and OSHA requirements. Many machines use food-grade stainless steel and FDA-approved plastics, ensuring compliance in handling cannabis extracts and pre-rolls.

What kind of maintenance is needed?

Routine maintenance typically includes daily cleaning of contact parts, weekly inspections of seals and gaskets, and periodic calibration of dosing systems. Components like needles, filters, or belts may require replacement depending on usage. Seasonal maintenance usually involves software updates and deeper servicing to ensure long-term reliability.

Will automation work with existing pre-rolls?

Yes. Many pre-roll infusion and packaging systems are designed for flexibility, handling different cone sizes, blunt wraps, and even tubes. Adjustable feeders, customizable dosing settings, and interchangeable parts make it easier to adapt machines to different product SKUs.

Is automation suitable for small businesses?

While automation is often associated with large enterprises, it can also benefit small craft cannabis producers. Compact, modular systems allow smaller operators to scale gradually without overwhelming upfront costs. For example, desktop vape cartridge fillers or small-batch pre-roll machines can help craft brands improve consistency and reduce labor while maintaining artisanal quality.