Closed-Loop vs. Open-Loop Systems in Cartridge Filling

The cartridge-filling industry continues to evolve as automation drives precision, consistency, and profitability. Among the most debated topics is the choice between closed-loop and open-loop systems. Both approaches influence the efficiency, quality control, and long-term return on investment for manufacturers.

Closed-loop systems rely on continuous feedback to adjust performance in real time, while open-loop systems operate based on preset commands without real-time correction. This difference may seem minor, but in high-volume cartridge production, it often determines whether businesses achieve accuracy, minimize waste, and remain compliant with industry standards.

This blog explores both systems in detail, presenting their working mechanisms, advantages, and trade-offs. Backed by authentic insights and research from authoritative sources, including the National Institute of Standards and Technology, USDA.gov, and peer-reviewed publications from ScienceDirect (PDF), we'll examine how each approach impacts production outcomes.

Comprehensive Guide to Cartridge Filling Systems

Cartridge filling requires precision because even the smallest errors in dosage can lead to inconsistent customer experiences or compliance issues. Whether using oil, vape liquid, or concentrates, the filler system must strike a balance between speed, accuracy, and repeatability.

Cartridge fillers operate either on feedback-driven systems (closed-loop) or fixed-input systems (open-loop).

Errors in filling can result in wasted product, customer complaints, or even regulatory fines in sensitive industries.

Advanced machines incorporate automation to reduce manual oversight, but the effectiveness of automation depends heavily on the chosen loop system.

Why does this matter?

Selecting between open-loop and closed-loop systems is not just a technical choice. It directly affects profitability, product quality, and compliance. Understanding how these systems differ is the first step in making an informed decision.

Open-Loop Filling: Function and Process

Open-loop systems operate on pre-programmed commands. Once the machine is set, it dispenses according to its instructions without monitoring real-time performance or making automatic adjustments.

Open-loop systems are generally simpler, less expensive, and easier to set up.

They rely heavily on initial calibration, and performance depends on consistent environmental and material conditions.

If variables change, such as oil viscosity, temperature, or cartridge material, the system continues filling without compensation, which can lead to errors.

If a batch of oil is thicker due to lower temperature, an open-loop filler may underfill cartridges because it lacks sensors to detect the change in viscosity. This issue is well-documented in studies on automation control limits in manufacturing.

Key points about open-loop systems:

Lower upfront cost.

Minimal complexity in setup.

Higher reliance on stable material properties.

Greater risk of inconsistencies when conditions vary

Closed-Loop Filling: Function and Advantages

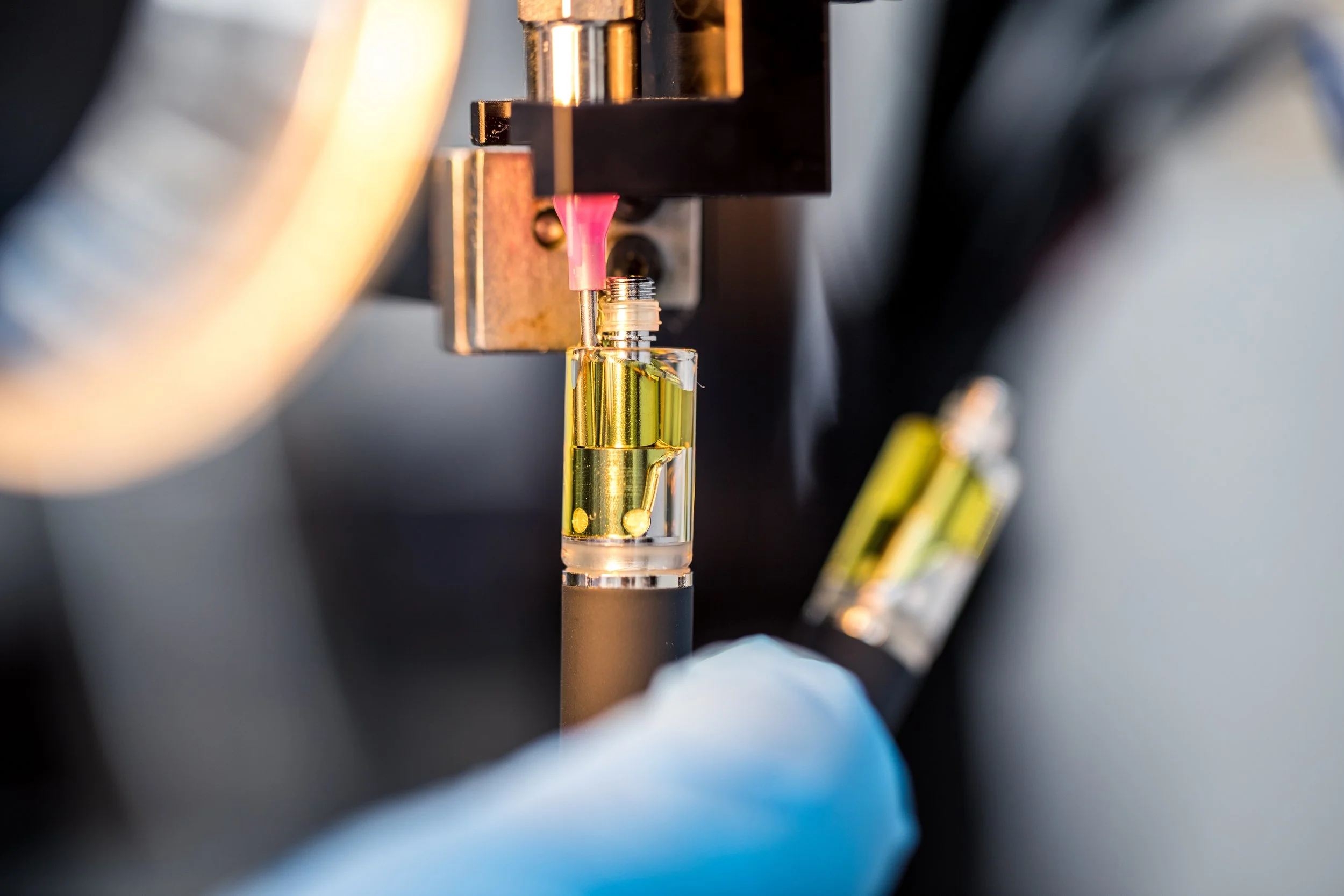

Closed-loop systems, by contrast, are designed to measure and adjust in real time. Using sensors and feedback mechanisms, these machines monitor performance continuously and correct errors instantly.

Closed-loop fillers detect variations in viscosity, temperature, or cartridge size, ensuring precise filling.

Adjustments are made immediately to maintain consistent fill levels.

These systems are often integrated with advanced automation and data collection tools.

The US Department of Energy highlights feedback-based automation as one of the key drivers of efficiency in modern manufacturing, underscoring why closed-loop systems outperform open-loop in dynamic environments.

Key benefits of closed-loop systems:

High precision and reduced product waste.

Better compliance with regulatory standards.

Real-time monitoring and analytics capabilities.

Scalability for high-volume production without compromising quality.

Evaluating Advantages Versus Disadvantages

While closed-loop systems offer advanced capabilities, both options have their strengths and trade-offs.

Open-loop advantages:

Lower initial cost.

Easier to maintain and repair.

Best for operations with stable and predictable inputs.

Open-loop disadvantages:

Susceptible to errors when external factors change.

Higher waste levels over time.

Less suited for high-volume or compliance-driven industries.

Closed-loop advantages:

Real-time error correction ensures consistent output.

Optimized for dynamic production environments.

A more substantial long-term ROI is achieved through reduced waste.

Closed-loop disadvantages:

Higher upfront investment.

More complex setup and training required.

Greater dependency on sensors and electronics for function.

Like in ensure consistent dosing in vape cartridge filling, the core value of closed-loop is maintaining accuracy batch after batch.

Studies from MIT on control systems confirm that closed-loop mechanisms outperform open-loop when variability is high, reinforcing the value of automation in complex production settings.

Real-World Applications and Insights

Different industries provide valuable case studies on the effectiveness of loop systems.

Vape and cartridge manufacturers: Closed-loop systems prevent underfilling or overfilling, improving compliance with quality standards.

Food and beverage industry: Open-loop systems are still used for consistent liquids, but feedback loops are increasingly preferred for complex packaging.

The pharmaceutical sector: Closed-loop control is often mandatory due to strict dosage requirements.

A National Library of Medicine publication confirms the use of feedback-based control systems in pharmaceutical filling to ensure accuracy and safety. This highlights the importance of closed-loop mechanisms in industries where dosage consistency has a significant impact on health outcomes.

Insights from industry adoption:

Companies that switched from open-loop to closed-loop reported significant reductions in product waste.

Manufacturers that leverage closed-loop systems often achieve compliance certifications more quickly.

Open-loop systems remain relevant in small-scale production where conditions are stable and margins are lower.

Finding the Optimal Cartridge Filling System for ROI

Return on investment (ROI) is often the deciding factor when choosing between open-loop and closed-loop filling systems. Businesses must evaluate both short-term affordability and long-term profitability to ensure sustainable growth and financial stability.

When open-loop makes sense:

Limited production runs with predictable inputs.

Lower capital budgets.

Small-scale operations with minimal compliance risk.

When closed-loop makes sense:

Large-scale production environments.

High-value or compliance-heavy industries.

Businesses aiming to reduce waste and optimize throughput.

The US EPA notes that reducing waste not only improves sustainability but also increases profitability, which aligns closely with the advantages of closed-loop systems.

ROI considerations:

Open-loop: low initial cost, higher risk of waste.

Closed-loop: higher initial cost, long-term savings through efficiency.

Cartridge Filling Automation: The Road Ahead

As the demand for cartridges grows, automation technologies will continue to evolve. Closed-loop systems are expected to become the standard as industries push for higher accuracy, compliance, and scalability.

The integration of AI and machine learning will improve predictive maintenance.

T-enabled closed-loop systems will allow remote monitoring and diagnostics.

Hybrid systems may emerge, blending the cost-effectiveness of open-loop control with the benefits of limited feedback.

Research from ScienceDirect highlights the future role of adaptive automation in manufacturing, pointing toward a gradual industry-wide shift toward closed-loop dominance.

Trends shaping the future:

Increased regulatory demands favor closed-loop.

Greater emphasis on sustainability and waste reduction.

Growing preference for modular, scalable machines.

The Path Forward in Cartridge Filling

The choice between closed-loop and open-loop systems depends on production goals, budget, and compliance requirements. While open-loop systems can serve small-scale or stable production environments, closed-loop technology delivers superior consistency, waste reduction, and scalability for modern manufacturing.

Ultimately, this decision reflects the same growth mindset as starting a vape brand with the right filler investing in precision and automation to safeguard profitability and long-term success.

For businesses seeking to strike a balance between efficiency and profitability, closed-loop systems emerge as the forward-thinking solution. They enhance accuracy, streamline compliance, and strengthen long-term ROI. In today's market, where precision defines success, automation supported by continuous feedback is no longer optional; it's essential.

Partner with Sorting Robotics to explore advanced cartridge filling solutions designed to help your operation scale faster, reduce costs, and stay ahead of evolving industry demands.

Frequently Asked Questions

What is the main difference between closed-loop and open-loop systems?

Closed-loop systems utilize sensors and feedback for precision, whereas open-loop systems rely on preset controls that do not require adjustments.

Why do manufacturers prefer closed-loop systems?

They ensure higher accuracy, reduce waste, and maintain consistency, which is critical in regulated vape manufacturing.

Are open-loop systems still valuable for production?

Yes, they are cost-effective for smaller operations where precision requirements and compliance demands are limited.

How does closed-loop filling improve ROI?

By reducing product loss, maintaining uniformity, and lowering rework costs, closed-loop systems achieve faster payback.

Which system is better for compliance with regulations?

Closed-loop systems provide traceable data and precision, making them more aligned with evolving industry standards.