Common Cartridge Filling Mistakes (and How Omni Solves Them)

Filling vape cartridges may seem simple, but in large-scale cannabis production, even small mistakes can cause leaks, clogs, or inconsistent dosing. These issues lead to wasted oil, product recalls, and frustrated customers. According to Research, consumer satisfaction in the e-cigarette and vape sector is strongly influenced by product quality and reliability, which means filling precision directly impacts both yield and brand reputation.

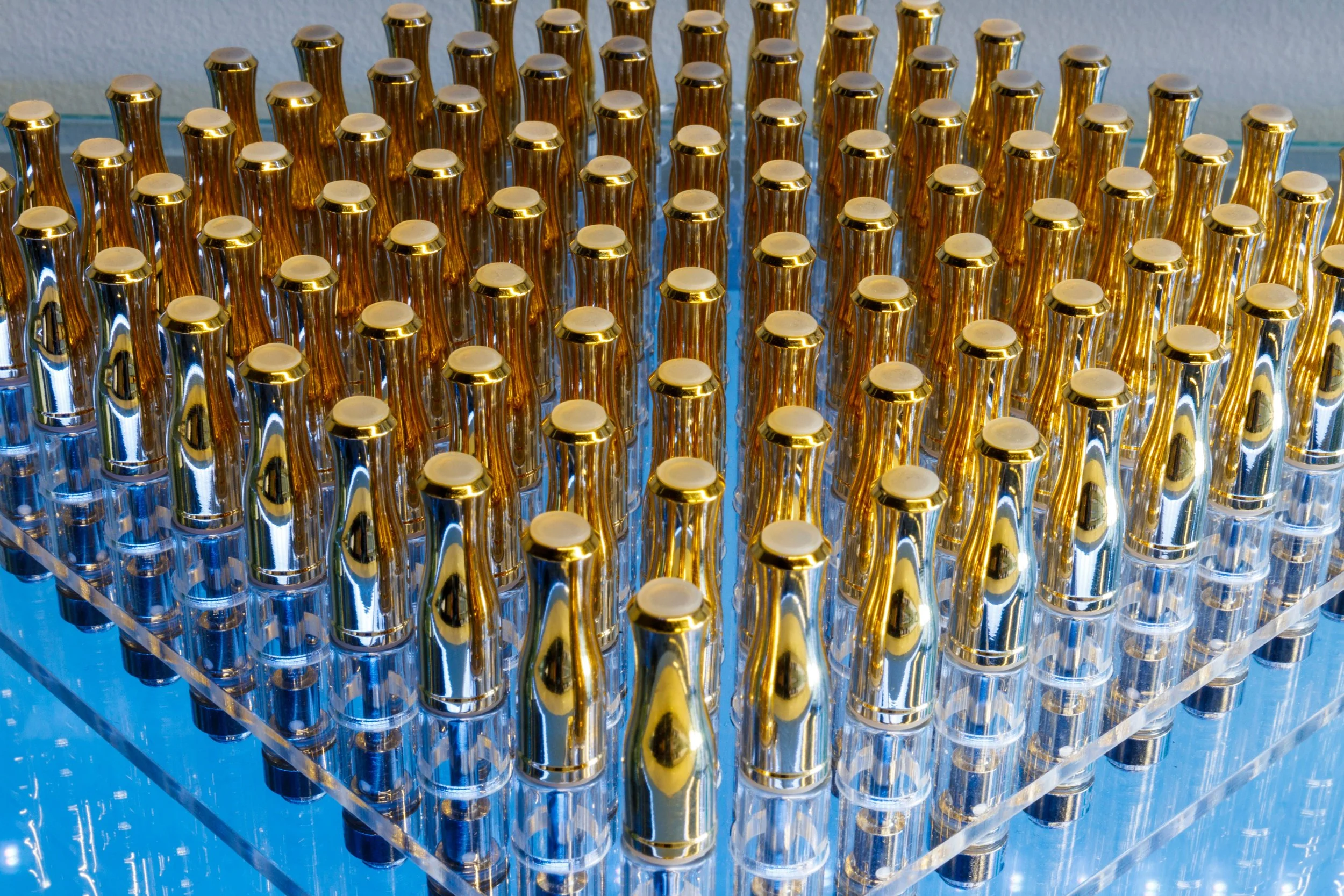

This blog highlights the most common mistakes in cartridge filling. It explains how the Omni-Filler desktop vape cartridge filling machine from Sorting Robotics solves them, helping cannabis brands improve accuracy, reduce waste, and scale with confidence.

Common Cartridge Filling Mistakes

Minor dosing errors can create waste, compliance risks, and inconsistent product quality. Meanwhile, the vape cartridge market is rapidly expanding, valued at USD 1.81 billion in 2024 and projected to reach USD 6.0 billion by 2030, making precise and scalable operations more essential than ever for meeting demand without sacrificing quality. These insights underscore why every detail, from cartridge filling to temperature, pressure, and viscosity management, as well as equipment reliability, has a direct impact on yield, efficiency, and consumer trust.

Below are the most common mistakes in cartridge filling, along with how the Omni automated filling system addresses them.

Mistake 1: Inconsistent Dosing

Manual or low-grade filling equipment often struggles to maintain exact fill levels. Some cartridges end up underfilled, while others overflow, which can harm compliance, yield, and consumer trust—issues that stem directly from the difference between manual and automatic cartridge filling

How Omni Solves It: Omni delivers precise dosing control down to the microliter level, ensuring every cartridge meets exact specifications. This eliminates human error and protects brand reliability.

Mistake 2: Oil Leaks and Seal Failures

Thick oils can often leak during filling if temperature or volume isn't properly controlled. Leaks reduce margins and damage consumer perception, which is why many operators follow best practices from how to avoid leaks and clogs when filling vape carts to protect both yield and brand reputation.

How Omni Solves It: Omni-Filler's precision filling system helps stabilize oils during dispensing, minimizing dripping and ensuring clean fills.

Mistake 3: Clogging with High-Viscosity Oils

Rosin, live resin, and other sticky extracts can clog needles, slowing production and requiring frequent maintenance.

How Omni Solves It: Omni-Filler's precision filling capabilities help enable smooth, consistent fills. This reduces clogs, waste, and downtime.

Mistake 4: Slow Throughput in Scaling Operations

Hand-filling or outdated machines can't keep pace with demand. Bottlenecks delay deliveries and reduce profitability.

How Omni Solves It: Omni fills hundreds of cartridges per hour with consistent accuracy. Automation reduces labor dependency and maintains scalable output without compromising quality.

Mistake 5: Poor Cleanability and Cross-Contamination

Residual oil inside filling systems can cause cross-contamination between SKUs and lengthen cleaning downtime. Poor sanitation is also a compliance risk in regulated markets.

How Omni Solves It: Omni is designed with easy-to-clean pathways and tool-free disassembly, allowing faster SKU changes and improved compliance with hygiene standards.

Maintenance and Long-Term Reliability

Omni-Filler is designed to deliver consistent performance. Key features include:

Durable build: Stainless steel components withstand continuous high-volume use.

Non-stick flow paths: Reduce residue buildup and minimize clogging.

Tool-free maintenance: Quick disassembly makes cleaning fast and simple.

Shorter cleaning cycles: Routine sanitation takes minutes, not hours.

Lower operating costs: Less downtime and fewer replacement parts help maintain a strong ROI.

Operator Training and Support

Omni is built to simplify onboarding and daily operation, reducing the need for specialized technical expertise:

Intuitive interface: Easy-to-use controls shorten the learning curve for new staff.

Guided onboarding & remote support: Ensure quick setup and minimal downtime.

Real-time monitoring: Alerts operators to performance issues early, preventing costly errors.

Future-Proof Technology

Omni is engineered to keep pace with an evolving cannabis industry, protecting your investment long-term:

Modular design: Scales and adapts as production volumes increase.

Broad compatibility: Works with a wide range of cartridge sizes, formats, and oil types.

Continuous software updates: Add new features and optimize performance without costly hardware replacements.

Why Cartridge Filling Precision Matters

Cartridge filling isn't just about efficiency; it directly affects compliance, customer trust, and profitability. Precision at this stage safeguards brands in several key ways:

Prevents compliance violations: Accurate dosing ensures every cartridge meets legal volume requirements in regulated cannabis markets.

Delivers a consistent consumer experience: Uniform fill levels protect product quality and brand reputation, building repeat customer loyalty.

Reduces waste and boosts margins: Less spillage, fewer rejects, and tighter control over oil usage translate into stronger profitability.

How Omni Improves ROI for Cannabis Brands

Omni isn't just about automation; it's about turning precision into profit. By streamlining workflows and eliminating common production pitfalls, the system delivers measurable returns:

Labor efficiency: One trained operator can oversee high-throughput filling, cutting labor costs and reducing staffing bottlenecks.

Reduced waste: Microliter-level dosing accuracy ensures minimal oil loss, protecting margins on every batch.

Scalable growth: Omni adapts to expanding production demands, supporting everything from pilot runs to enterprise-scale output without sacrificing quality.

Integration and Ease of Use

Omni is designed to integrate seamlessly into existing workflows, requiring no complex setup or lengthy training. Its plug-and-play design allows operators to get up and running quickly, while the intuitive touchscreen interface simplifies adjustments and monitoring.

Real-time production tracking through LAKA, Sorting Robotics' native production analytics software included with all their solutions, keeps managers informed, and Omni-Filler's high-precision filling makes it a strong fit for cannabis facilities looking to scale with confidence.

Why Omni is the Smarter Choice

From dosing errors to clogs and contamination risks, cartridge filling mistakes cost cannabis brands time, money, and reputation. The Omni automated filling system is engineered to eliminate these challenges with precision dosing, heat control, high throughput, and easy maintenance.

Upgrade your cartridge production with Omni from Sorting Robotics. Visit us today to schedule a demo and discover how automation can enhance your filling process.

Frequently Asked Questions

1. What cartridge sizes can Omni handle?

Omni-Filler is designed for high-precision vape cartridge filling, with flexibility across production needs.

2. Can Omni fill disposable vape pens as well as cartridges?

Yes. Omni is designed to work with standard cartridges and disposable all-in-one vape pens, making it versatile for different SKUs.

3. How does Omni maintain accuracy over long production runs?

Its precision dosing system and real-time monitoring ensure consistency even during continuous, high-throughput operation.

4. Does Omni require a dedicated operator?

No. Omni's automation allows one operator to manage multiple production tasks, freeing staff for higher-value work.

5. What facility setup is needed to install Omni?

Omni requires only standard electrical connections and a clean workspace, with no special infrastructure or major renovations needed.