Seamless Integration of Jiko, Stardust & Omni into Production Lines

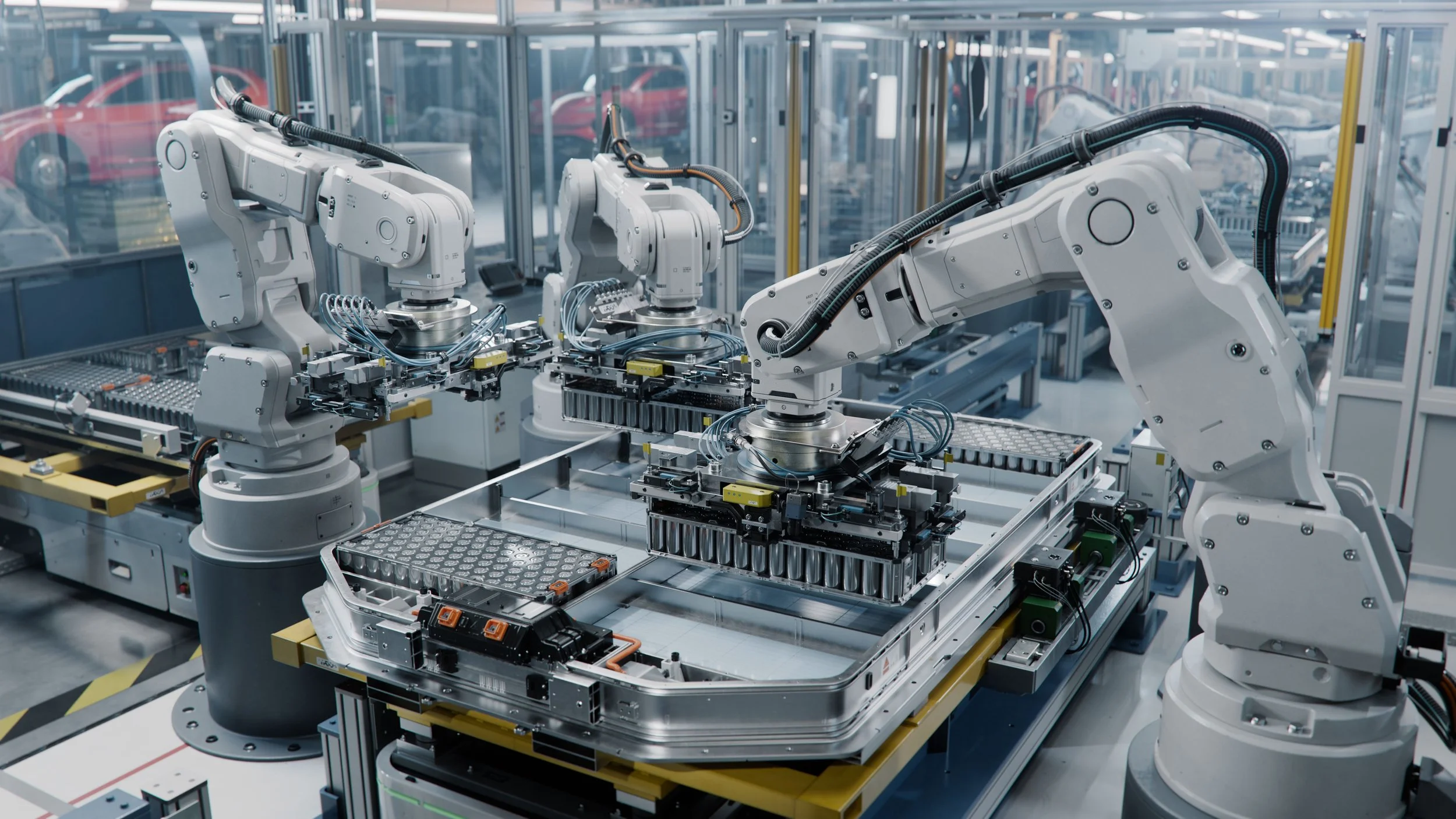

The cannabis industry is rapidly evolving, with automation technologies playing a crucial role in streamlining production, enhancing quality, and driving scalability. As demand grows, integrating advanced automation systems becomes essential to maintain consistent product standards. Innovations like Sorting Robotics' Jiko, Stardust, and Omni offer cutting-edge solutions for automating key production steps. However, optimizing their benefits requires seamless integration and expert consulting.

Machine Design’s 2025 Feature on Sorting Robotics Highlights how Jiko infuses concentrates into pre-rolls and how Stardust applies coatings, like kief, with robotic precision, reducing costs and improving consistency.

In this guide, we explain how these systems can be effectively incorporated into production lines to maximize efficiency, consistency, and return on investment.

What is Jiko, Stardust & Omni Integration in Cannabis Production?

The integration of Jiko, Stardust, and Omni into cannabis production lines involves combining these automation systems with existing production infrastructure to enhance operations.

Jiko automates the pre-roll infusion process, ensuring precise dosing with high throughput.

Stardust provides automated key coating, delivering consistent product quality while maintaining speed.

Omni optimizes vape cartridge filling, ensuring precise and consistent dosing for cannabis concentrates.

Each system is designed to seamlessly integrate with conveyors, packaging lines, and other critical components of the production process, making them essential for businesses looking to scale without compromising on quality.

The Midwestern Hemp Research Collaborative (2022–2026) investigates agronomic factors crucial for industrial hemp production; this research platform could serve as a model for future investigations into automation integration.

Why Is Integration So Important for Cannabis Production?

Integrating Jiko, Stardust, and Omni into production lines offers substantial operational advantages that go beyond just automation.

1. Increased Operational Efficiency

Automation of tasks that traditionally required significant labor, such as pre-roll infusion, kief coating, and cartridge filling, results in faster production speeds and lower labor costs. For instance, Jiko can infuse up to 1,000 joints per hour, and Stardust can coat up to 1,500 joints per hour, far exceeding manual production capacities. The vape cartridge filling machine’s efficiency directly translates to increased throughput, enabling manufacturers to meet rising consumer demand.

2. Consistency & Quality Assurance

Cannabis products, particularly pre-rolls and vape cartridges, are sensitive to variation in appearance, potency, and quality. Even minor deviations can affect both product efficacy and regulatory compliance. By integrating Jiko, Stardust, and Omni, cannabis businesses can ensure uniformity in every batch. These systems utilize precision automation to maintain consistent quality, providing peace of mind that every product adheres to the company's quality standards.

3. Scalability

As cannabis businesses grow, so do their operational needs. Integrating automation allows companies to scale production lines without significantly increasing labor costs. With these systems, businesses can handle large volumes of production while maintaining the same level of quality control. Automation enables companies to meet demand spikes without the need to hire additional staff, thus optimizing profitability and operational scalability.

NIST research highlights that automated manufacturing technologies can significantly enhance production scalability and efficiency.

How Integration Improves Compliance and Reduces Risk

Compliance is a critical factor in the cannabis industry, where strict regulations govern every aspect of production. Automation technologies like Jiko, Stardust, and Omni can help companies avoid common pitfalls that lead to non-compliance:

Precise Dosing and Infusion: Jiko's precision dosing technology ensures that every infused pre-roll is accurately dosed, reducing the risk of label inaccuracies or misbranding. By automating this process, businesses can meet legal requirements while avoiding costly mistakes.

Kief Coating Compliance: Stardust's kief coating system ensures that the application of kief is uniform, reducing the risk of contamination or uneven product quality that might violate regulations.

Consistent Cartridge Filling: Omni's ability to precisely fill vape cartridges automatically ensures consistent potency across batches, an essential aspect of meeting both legal requirements and consumer expectations.

These automation systems provide an audit trail of the production process, supporting compliance reporting and minimizing the likelihood of costly fines or product recalls.

The Importance of Expert Consulting for Integration

While the individual capabilities of Jiko and Stardust, Omni are impressive, their successful integration into existing production lines requires careful planning and expert consultation. Consulting ensures these technologies are not only compatible with your systems but are optimized for your specific operational goals, often involving custom machinery design for Jiko and Stardust beyond standard configurations.

Why Choose Expert Consulting?

Expert consultants help businesses:

Select the Right System Configuration: With an understanding of each company's unique workflow and production requirements, consultants can recommend the best configuration of Jiko, Stardust, and Omni to maximize efficiency.

Ensure Seamless Integration: Consultants ensure these systems are effectively integrated into existing production lines, reducing downtime and minimizing disruptions during installation.

Optimize System Performance: Ongoing consulting helps businesses fine-tune these systems to meet evolving production needs, ensuring they continue to perform at peak levels as demand grows.

Key Benefits of Expert Consulting for Automation Integration

Based on industry case studies and vendor-reported results, expert consulting can significantly improve automation outcomes in cannabis manufacturing:

Benefits, Operational Impact & Examples

| Benefit | Impact on Operations | Example |

|---|---|---|

| Improved Product Consistency | Uniform product quality across batches | Vendors report over 95% of pre-rolls meeting premium criteria |

| Reduced Waste | Fewer rejections post-processing, minimizing product loss | Up to 15% waste reduction during pre-roll infusion (case study data) |

| Increased Throughput | Significant speed improvements in production | Systems can process up to 1,500 joints/hour, depending on configuration |

| Compliance Assurance | Automatic adherence to legal standards | Reduced risk of non-compliance through consistent testing |

| Scalability | Easily scalable systems to grow with demand | Modular upgrades to handle increasing production volume |

While U.S. government research on specific automation systems like Jiko, Stardust, and Omni is limited, the USDA–NIFA’s Industrial Hemp Program and projects like the Midwestern Hemp Research Collaborative highlight strong federal support for innovations in hemp production. This broader research framework creates fertile ground for integrating advanced automation to enhance efficiency and compliance.

The Integration Process: What to Expect

Integrating Jiko, Stardust, and Omni into your production lines involves a step-by-step approach, with expert consultants guiding the process at each stage:

Operational Audit: Analyzing current workflows and identifying inefficiencies.

Technology Assessment: Determining the ideal configuration of Jiko, Stardust, and Omni for your production needs.

System Integration Blueprint: Developing a plan for integrating automation systems with existing equipment.

Pilot Testing: Running a pilot deployment to test system performance in real-world conditions.

Ongoing Performance Optimization: Continuously adjusting system settings to ensure peak performance as production needs change.

Transform Your Production with Sorting Robotics Automation

Integrating Jiko, Stardust, and Omni into cannabis production lines provides clear advantages in efficiency, consistency, and compliance. However, the key to maximizing these benefits lies in expert consulting to ensure smooth integration and ongoing optimization.

At Sorting Robotics, we specialize in helping cannabis businesses integrate these automation systems into their workflows, enhancing productivity, reducing waste, and ensuring compliance. If you're ready to scale your cannabis production with precision and efficiency, contact Sorting Robotics today for Robotics Integration Services and begin transforming your cannabis manufacturing operations.

Frequently Asked Questions

What are Jiko, Stardust, and Omni, and what specific functions do they serve in cannabis production?

Jiko is an automated pre-roll infusion robot that precisely controls temperature and pressure for concentrate dosing inside cannabis pre-rolls. Stardust is the world’s first automated kief coating robot that applies an even coat of concentrate and powder (kief, THCa diamonds, bubble hash) onto pre-rolls in a fully enclosed environment with HEPA filtration.Omni is a desktop vape cartridge filling machine that ensures fast, accurate, and repeatable filling of vape cartridges to exact specifications.

How do these machines integrate into existing cannabis production lines?

They are designed to be interoperable, allowing robotic arms or conveyor systems to transfer products between machines seamlessly without manual handling. The systems communicate digitally, enabling a fully automated workflow that stitches together all stages of pre-roll and vape cartridge production, reducing labor and increasing throughput.

What efficiency and quality benefits do Jiko, Stardust, and Omni bring?

These machines provide consistent dosing, uniform coating, and precise filling, reducing manual errors, waste, and variability. Stardust can coat 900-1200 pre-rolls per hour, and the combined automation triples output while improving product consistency and brand reliability.

What safety features are incorporated to protect operators and maintain product quality?

Stardust operates inside a fully enclosed cabinet with vacuum extraction, HEPA filtration, and air quality monitoring to contain cannabis dust and vapors. This minimizes operator exposure to airborne particulates, which is crucial for workplace safety in cannabis manufacturing facilities.

Is technical support and training provided for integrating these systems?

Yes, manufacturers like Sorting Robotics offer comprehensive setup assistance, on-site training, routine maintenance guidance, and continuous support to ensure smooth implementation and reliable operation within production lines. The systems are designed to be user-friendly and plug-and-play ready.