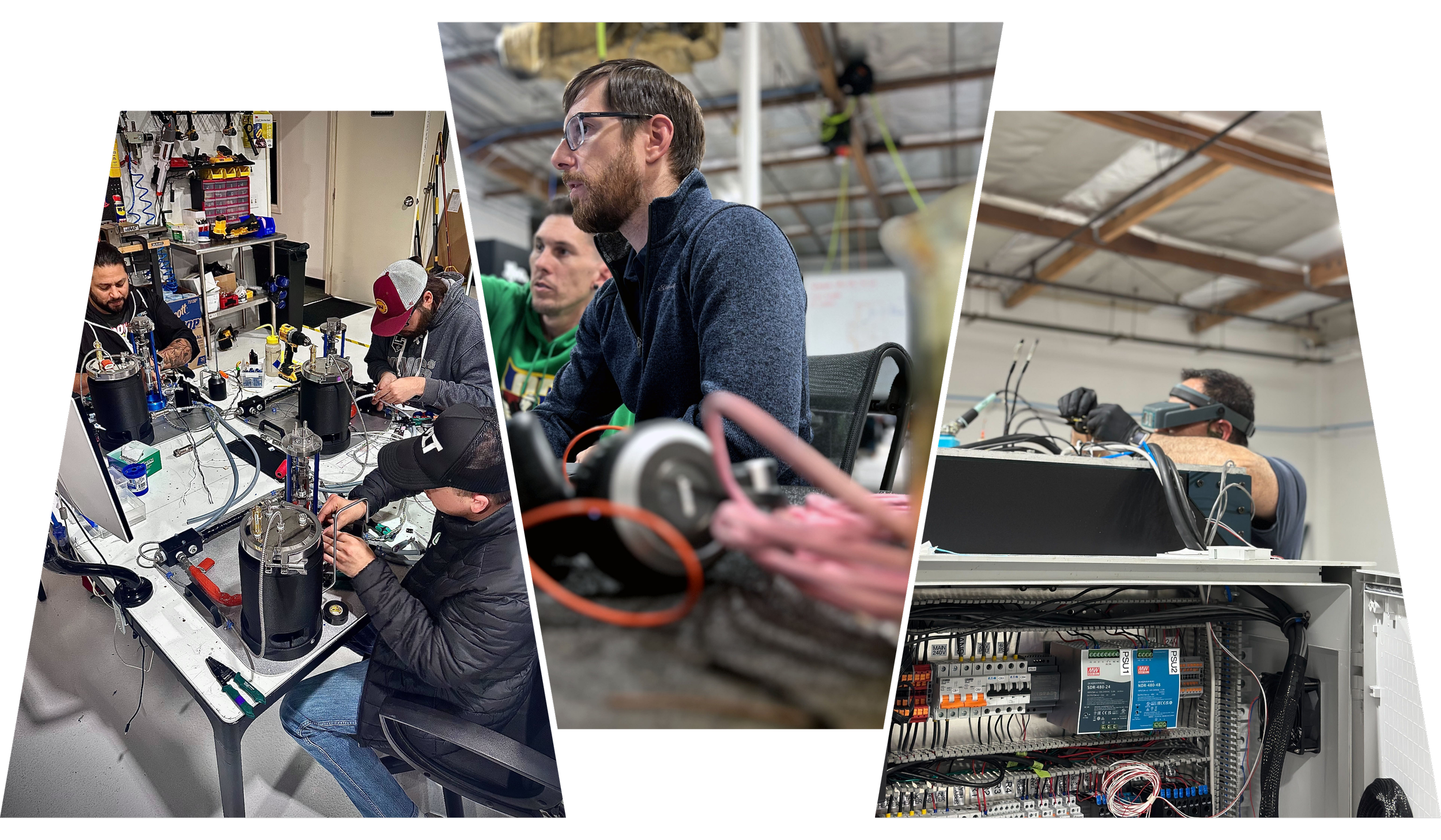

Custom Robotics and Automation for Cannabis Manufacturing.

We design, engineer, and integrate custom cannabis automation systems. From infused pre-rolls to packaging lines, we tailor to your production floor.

Cannabis-Focused Manufacturing Design and Robotics Consulting.

No two cannabis operations run the same and that’s exactly why off-brand automation doesn’t cut it. We design, build, and integrate custom robotics solutions tailored to your SKUs, facility layout, and throughput goals. Whether you're launching a new product line or scaling existing production, our team delivers cannabis-focused robotics integration that fits your operation and performs on day one.

Standard Automation Doesn’t Work for Cannabis.

Standard manufacturing robots built for traditional industries fail to meet the demands of cannabis production. They struggle with resin buildup, flower fragility, and pre-roll throughput. True efficiency comes from cannabis-focused robotics integration and custom automation developed through manufacturing design consulting.

Off-Brand Robotics Don’t Fit Cannabis Production

Poor System Fit Creates Hidden Labor Costs

When machines aren’t designed for cannabis, operators are left modifying equipment, adjusting workflows, and adding manual labor to compensate. These patchwork solutions increase costs, reduce efficiency, and undermine the promise of automation. True robotics integration requires systems built to fit your process from the start.

High Labor Dependency Creates Bottlenecks

Relying on manual labor to run cannabis production lines leads to missed targets, inconsistent output, and rising costs. Our robotics consulting and manufacturing design services replace high-labor tasks with automated systems engineered to scale as your business grows.

Bespoke Solutions

Custom Machines & Modifications

-

Our approach starts with in-person manufacturing design consulting. We study your SKUs, evaluate throughput demands, and map your facility layout. Then we build automation that matches it all. From nozzle engineering to full system layouts, you get consistent, high-speed performance.

-

We adapt mechanics, software, and UI to match your SOPs, floorplan, and product specs. Whether you’re running hybrid concentrates, odd-sized wraps, or changing formats, your automation stays compatible and scalable.

End-to-End Line Integration

-

We handle the mechanical, electrical, and software integration between machines so your line runs like one system instead of five disconnected units. From loading trays to finished goods, we make automation feel seamless.

-

System integration means more than hardware alignment. We coordinate mechanical handoffs, software logic, and machine timing to match your production targets. Every connection is engineered for throughput, space, and labor efficiency.

Product Development Work

-

Prototyping with us means real engineering, not one-off hacks. We work with your team to design, build, and iterate hardware for new product formats. Every system is built to evolve from testing to repeatable, high-throughput production.

-

We work with your team from early design through launch. That means refining product specs, assessing manufacturability, and building automation strategies that scale. Your best ideas shouldn’t get blocked by bad tooling or limited systems.

Built With Experience.

Proven in the Field.

Nova Farms

"Expanded product line with minimal effort. Nova's infused preroll and blunt filling (infusion) is going very well.”

Rise Copacking

“Amongst everyone in the space, Sorting Robotics was by far the most data-driven team I’ve worked with. They didn’t just look at metrics — they understood them, analyzed them, and helped us build the right ones.”

Motiff Labs

“They helped us expand grow into the canadian infused pre-roll market and are always open to improvements."

Flow Distribution

“Sometimes the machine works so well it actually catches up to our pre-roll machine. Once we dialed in our process, it's been running smooth every day; it just fits right into the workflow.”

Delta Munchies

Check out our case study with Delta Munchies!

More Testimonials

Hear from other satisfied clients!

Ready to Build the Line You Actually Need?

Let’s talk about what’s slowing you down — and build the solution together.

Check Out Our Robots

Jiko+

Go beyond the basics with Jiko+: automation that adapts to your growing business needs.

LAKA Production Data

Native Production Analytics software and Real Time Monitoring - included on all Sorting Robotics solutions.

Stardust

With Stardust, infuse, coat, and create premium products faster and more consistently.