Custom Robotics Integration Services for Manufacturers

Custom robotics integration helps overcome labor shortages, improve efficiency, and ensure consistent product quality. The cannabis trimming machines market reached approximately $120 million in 2023 and is expected to surge to nearly $450 million by 2032, highlighting the fast-growing adoption of automated solutions across the industry.

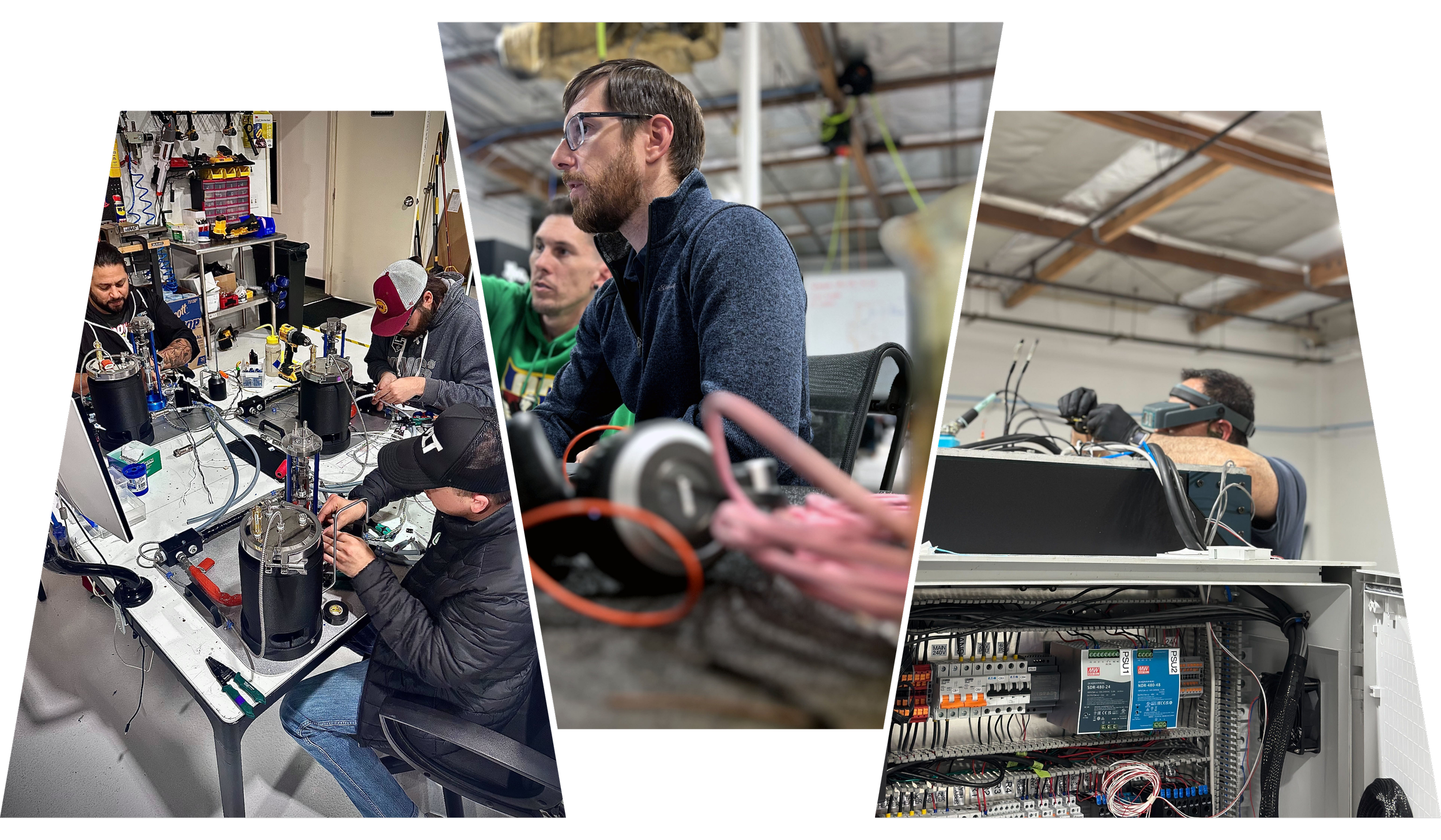

Sorting Robotics specializes in AI-driven, precision-engineered systems tailored for cannabis production. Our custom automation solutions seamlessly integrate into your facility, enhance efficiency, reduce labor costs, and ensure your product quality exceeds the competition.

Why Cannabis Producers Prefer Custom Robotics Solutions in 2026

According to the National Cannabis Industry Association, labor shortages in 2021 created a significant risk for cannabis operators. As a producer, you need to make sure your production is integrated with smart automation to face these challenges head-on.

Here are some of the most common issues that custom automation can solve:

Overcome Labor Shortages & Reduce Costs

The cannabis industry struggles with labor shortages and rising wages. Manual trimming and sorting require intensive effort, often causing delays and increasing expenses. Automation reduces the need for manual labor and cuts operational costs.

Ensure Consistent & High-Quality Products

Quality consistency is crucial for brand reputation and customer trust. Manual handling can cause uneven trimming and packaging, whereas robotics delivers precise and uniform processing that preserves product integrity.

Increase Production Speed Without Losing Quality

Speed to market affects profitability. Manual processes are slow and prone to mistakes. Automated systems speed up production while adapting to plant differences, maintaining quality even at higher volumes.

Why Sorting Robotics Is the Trusted Partner for Cannabis Automation

With the cannabis vertical farming market set to grow from USD 526M in 2024 to USD 1.6B by 2030, producers are turning to precision robotics to stay competitive. Boost your production, elevate quality, and claim a bigger share of the booming cannabis market with Sorting Robotics' advanced automation solutions built for your operation.

No two cannabis operations are alike. Sorting Robotics designs and builds robotic systems that align with your specific facility layout, product types, and production volumes. Whether you need sorting, trimming, or packaging robots, our custom solutions integrate seamlessly to complement your existing processes and scale alongside your business growth.

Customized Robotics Tailored to Your Unique Workflow

Proven Success in Streamlining Cannabis Operations

Sorting Robotics has a track record of successfully deploying custom automation systems for cannabis producers. Our clients experience measurable improvements in efficiency, quality control, and compliance. We tailor every robotics solution based on your facility's unique needs, workflow, and production goals to ensure maximum impact.

NASA-Level Engineering Meets AI-Powered Innovation

Our engineering team includes experts who have worked on NASA projects, bringing unmatched precision and reliability to our robotics designs. Sorting Robotics employs advanced AI algorithms that enhance automation accuracy and decision-making.

Comprehensive Custom Automation Services for Cannabis Producers

The cannabis packaging equipment market is rapidly growing, projected to rise from $1.9 billion in 2025 to $8.9 billion by 2035. Automated solutions already make up over 64% of this market, proving that automation is essential to stay competitive.

Sorting Robotics provides end-to-end services that cover every aspect of custom robotics integration in cannabis production. Here's what our custom integration brings to your cannabis business:

Custom Machines & Modifications

-

After assessment, our engineering team designs custom robotic systems optimized for your cannabis production environment. Using AI and robotics technology, we develop equipment that handles delicate plant material efficiently and consistently, reducing waste and boosting output.

End-to-End Line Integration

-

Our custom robotics solutions do more than automate tasks; they connect your hardware with your existing software systems, including manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms.

-

Item descriptioOur process begins with a detailed consultation to understand your production challenges, goals, and facility capabilities. We assess workflows and pinpoint areas where automation will yield the greatest benefits.n

Product Development Work

-

We incorporate advanced sensors and software analytics into our systems, providing detailed production data in real time. This transparency helps you monitor performance, identify bottlenecks, and make informed decisions to improve your operations continuously.

-

Beyond installation, Sorting Robotics offers thorough training to your staff to ensure smooth adoption of new technologies. Our dedicated support team provides ongoing assistance and system upgrades to maintain optimal performance as your business evolves.

Built With Experience.

Proven in the Field.

Nova Farms

"Expanded product line with minimal effort. Nova's infused preroll and blunt filling (infusion) is going very well.”

Rise Copacking

“Amongst everyone in the space, Sorting Robotics was by far the most data-driven team I’ve worked with. They didn’t just look at metrics — they understood them, analyzed them, and helped us build the right ones.”

Motiff Labs

“They helped us expand grow into the canadian infused pre-roll market and are always open to improvements."

Flow Distribution

“Sometimes the machine works so well it actually catches up to our pre-roll machine. Once we dialed in our process, it's been running smooth every day; it just fits right into the workflow.”

Delta Munchies

Check out our case study with Delta Munchies!

More Testimonials

Hear from other satisfied clients!

Ready to Build the Line You Actually Need?

Let’s talk about what’s slowing you down — and build the solution together.

How Our Custom Cannabis Robotics Integration Works

Our integration process is designed to be straightforward and minimally disruptive, allowing you to transition smoothly to automated cannabis production.

Here's how we help streamline your cannabis production line:

Personalized Consultation and Production Assessment

We start by engaging with your team to review your current processes and goals. This stage includes site visits, workflow analysis, and technology evaluation to create a roadmap for automation tailored to your needs.

Custom Design and Prototyping to Fit Your Goals

Next, we develop detailed designs and prototypes of the robotics systems, incorporating client feedback to refine the solution. This iterative approach ensures that the final product meets your production requirements.

Professional Installation and Seamless Automation Integration

Our experienced engineers manage installation and make sure all robotic systems integrate flawlessly with your facility's hardware and software. We minimize downtime and disruption by coordinating closely with your production schedule.

Thorough Testing, Training, and Launch Support

Before going live, we perform rigorous testing to validate system performance under real production conditions. We then provide comprehensive training to your operators and maintenance teams, followed by hands-on support during the launch phase.

Continuous Upgrades and Dedicated Support

Automation needs to evolve. Sorting Robotics remains your partner with ongoing system upgrades, troubleshooting, and performance optimization to keep your operations running at peak efficiency.

The Benefits You'll Gain from Our Custom Robotics Integration

Investing in custom cannabis robotics delivers multiple advantages that drive your business forward. Here's how your business can get the edge over the competition with Sorting Robotics:

Accelerate Production and Increase Throughput

Automating manual tasks speeds up your entire production line, enabling higher volumes without sacrificing quality. Faster throughput means you can meet growing demand and seize new market opportunities.

Improve Product Quality and Consistency

Our robotics systems provide precise handling and processing, reducing variability and improving overall product uniformity. Consistent quality helps build customer loyalty and meets stringent regulatory requirements.

Reduce Labor Costs and Minimize Errors

Custom automation lowers your reliance on manual labor, reducing labor expenses and the risk of human error. This leads to cost savings and more reliable production output.

Scale Easily as Your Business Grows

Sorting Robotics designs flexible systems that adapt to expanding operations. As your production needs evolve, your robotics can scale accordingly without costly overhauls.

Gain Insights with Advanced Data Analytics

With integrated real-time monitoring and analytics, you gain valuable insights into your production processes. Data-driven decisions help you optimize performance and reduce downtime.

Not Just Cannabis, Our Robotics Integrates Across Diverse Industries

Agriculture and Horticulture

Our automated systems manage planting, sorting, and packing for delicate crops without damaging them. This allows growers to increase yield, reduce manual labor needs, and meet seasonal demands.

Logistics, Warehousing, and Fulfillment

From automated picking to palletizing and real-time inventory tracking, we make fulfillment faster and more accurate. Sorting Robotics solutions connect directly to WMS and ERP systems for a seamless operation.

Cosmetics and Personal Care

We create robots for precise filling, capping, and labeling of cosmetics and skincare products. These systems keep packaging uniform while meeting the demands of fast-moving production schedules.

Healthcare and Rehabilitation

We design automation for sterile transport, medication dispensing, and rehabilitation aids. Our solutions help improve patient care efficiency while supporting healthcare staff with time-saving tools.

Education, Research, and Laboratory Automation

Our robotics handles sample preparation, liquid handling, and repetitive lab tasks. By automating these processes, we help researchers save time, reduce errors, and focus on innovation.

Frequently Asked Questions

At Sorting Robotics, we design automation systems that go beyond cannabis production. Our precision-engineered robotics handle delicate, high-volume, and repetitive tasks across many sectors. Here are some of the top industries where our solutions deliver measurable results:

Food and Beverage

We build robotics that handle portioning, filling, sorting, and hygienic packaging with consistent accuracy. Our systems use food-safe materials and washdown-ready designs to meet strict safety standards while keeping production moving without delays.

Pharmaceuticals and Medical Devices

From cleanroom-ready packaging to precise dosing and inspection, our robots maintain regulatory compliance while improving output. Sorting Robotics provides full data traceability to help you meet safety requirements and achieve faster time-to-market.

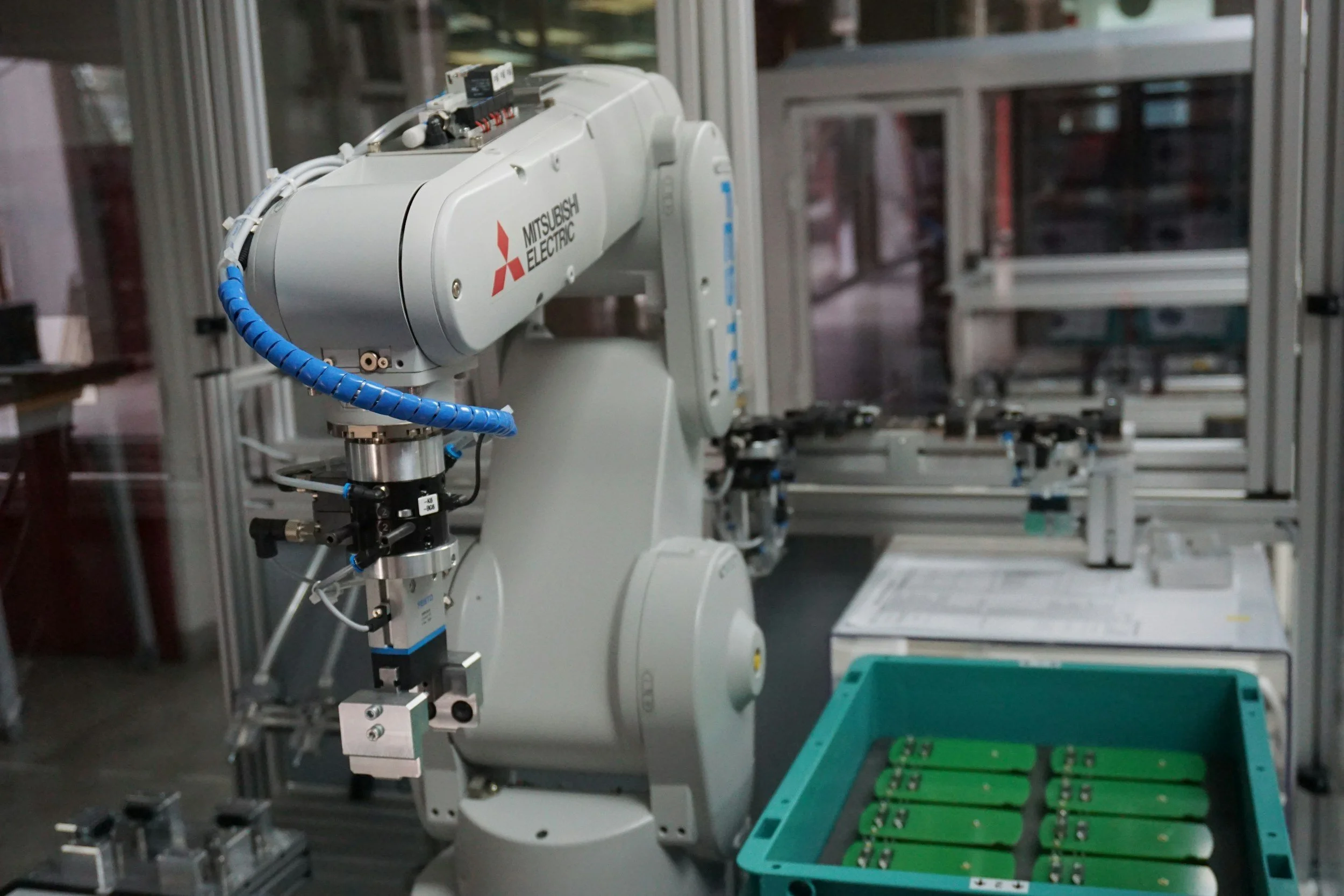

Electronics and Semiconductor Manufacturing

Our high-precision pick-and-place systems handle small, delicate parts with repeatable accuracy. We integrate vision-guided inspection tools to reduce defects and speed up assembly lines without sacrificing quality.

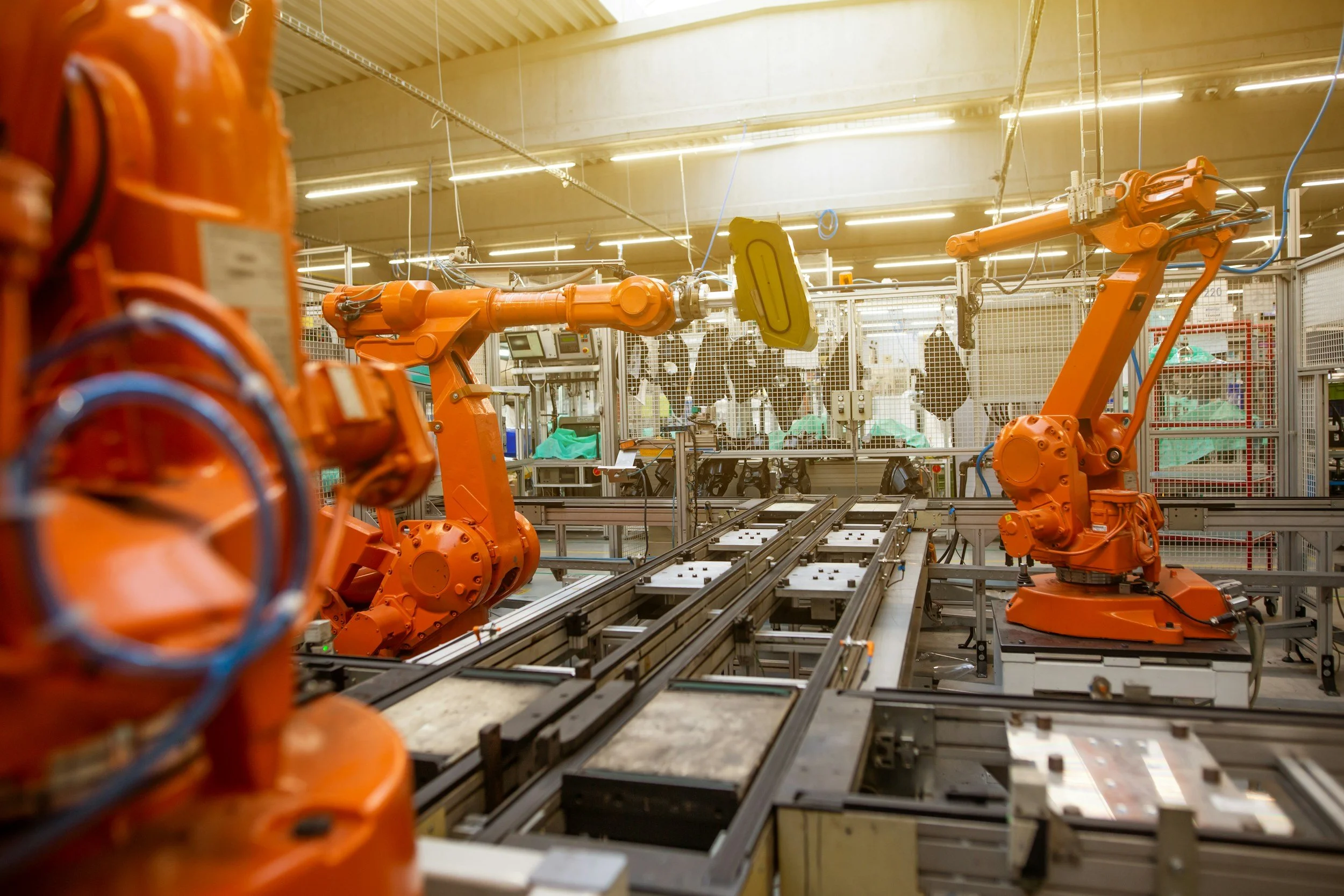

Automotive and General Manufacturing

We deliver robotics that automate assembly, part handling, and quality checks to keep production consistent and costs under control. Our systems integrate smoothly into existing workflows, reducing downtime and improving throughput.

Aerospace

We provide specialized robotics for drilling, fastening, and inspection processes that meet strict aerospace quality standards. Our solutions help streamline complex assembly while maintaining the highest levels of safety and accuracy.

-

Custom robotics automates labor-intensive tasks like trimming, sorting, and packaging, boosting efficiency, reducing errors, and ensuring consistent product quality.

-

No. Our custom robotics solutions are designed to integrate smoothly with your existing workflows and software, minimizing downtime during installation.

-

Implementation time varies by facility size and complexity but typically ranges from a few weeks to a few months, including design, installation, and staff training.

-

Yes. Custom systems use AI and adaptable engineering to process various strains and plant sizes while maintaining product integrity.

-

Ongoing support includes training, maintenance, software updates, and troubleshooting to ensure optimal system performance.

-

Automation reduces reliance on manual labor for repetitive tasks, lowering labor costs while improving speed and accuracy across your production line.

Take Your Cannabis Production to the Next Level with Automation

Discover how Sorting Robotics' custom cannabis robotics integration services can revolutionize your production line. Connect with our expert team for a consultation tailored to your facility's unique needs. Future-proof your cannabis business with automation solutions that deliver speed, quality, and scalability.

Contact Sorting Robotics now and start your journey toward more innovative, more efficient cannabis production!

Check Out Our Robots

Jiko+

Go beyond the basics with Jiko+: automation that adapts to your growing business needs.

LAKA Production Data

Native Production Analytics software and Real Time Monitoring - included on all Sorting Robotics solutions.

Stardust

With Stardust, infuse, coat, and create premium products faster and more consistently.