Cannabis Automation: A Comprehensive Guide

If you are exploring ways to cut labor costs, increase throughput, or bring consistency to your cannabis production line, you are in the right place. Whether you run a craft grow or a large-scale facility, the pressure to automate is real, and the options can feel overwhelming. We built this guide to walk you through every stage of cannabis automation so you can make informed decisions for your operation.

Cannabis automation is the application of robotics, IoT sensors, AI, and machine-controlled systems to every phase of cannabis production, from cultivation and harvesting through extraction, pre-roll manufacturing, packaging, and compliance tracking. According to Flowhub, 2026: the U.S. cannabis market is projected to reach nearly $47 billion, yet the industry supports only 425,002 full-time equivalent jobs, creating persistent labor shortages that make automation essential for competitive viability.

Across this guide, we trace the full production lifecycle. We start with the market forces and operational pain points pushing producers toward automation, then move into cultivation systems that control light, climate, and nutrients with precision. From there, we cover how vision systems and robotic trimmers are redefining harvest efficiency, followed by post-harvest processing where automated drying, curing, and extraction protect product quality and worker safety. We then break down the fastest-growing segment (pre-roll production and infusion automation, including specialty formats like hash holes and kief coating) before examining packaging, filling, labeling, and compliance tracking. Finally, we look at the underlying technologies powering these systems and how to evaluate automation for your specific operation.

Legalization momentum, labor shortages, and price compression are forcing cannabis producers to adopt automation or fall behind.

Cultivation automation integrates LED lighting, HVAC, CO2, and fertigation systems to reduce operating costs and stabilize growing environments.

Vision-based harvest timing and robotic trimming replace subjective human assessment with data-driven precision at scale.

Automated drying, curing, and extraction systems preserve terpene profiles, improve safety, and maximize throughput.

Pre-roll automation slashes per-unit costs, enables specialty infusion formats, and delivers payback periods as short as three to six months.

Packaging and filling automation handles weighing, cartridge filling, labeling, tax stamping, and tamper-evident sealing across all product types.

Automation strengthens consistency, reduces waste, cuts labor costs, and improves worker safety across every production stage.

Seed-to-sale tracking and automated compliance reporting minimize regulatory risk and audit exposure.

IoT, AI, computer vision, and cloud-based platforms form the technological foundation enabling connected, remotely managed operations.

Evaluating your operation's specific bottlenecks is the first step toward choosing the right automation systems.

Quick Tip

Start by auditing your highest-cost, most repetitive production step; that single bottleneck is where automation will deliver the fastest return and the clearest proof of concept for broader adoption.

We begin by examining the market dynamics, regulatory shifts, and operational challenges that have made automation a necessity rather than a luxury for cannabis producers at every scale.

Why Is Automation Reshaping the Cannabis Industry?

Automation is reshaping the cannabis industry because exponential market growth, changing legislation, and rising consumer demand have outpaced what manual labor can sustain. The cannabis industry has experienced rapid expansion over the past several years, and that trajectory shows no signs of slowing. According to Flowhub's 2026 Cannabis Industry Statistics, the U.S. cannabis market is projected to reach nearly $47 billion in 2026, while cannabis added approximately $149 billion to the broader economy in 2025.

This growth creates enormous pressure on cultivators and producers. With adult-use cannabis now legal in 24 states (Flowhub, 2026), the regulatory patchwork alone demands operational precision that manual processes struggle to deliver. Although the industry supports 425,002 full-time equivalent jobs according to the same Flowhub report, persistent labor shortages continue to widen the gap between production capacity and consumer demand.

Automation has revolutionized industries relying on human labor, and cannabis is following that same pattern. When a 2025 RollPros analysis found that manual pre-roll production costs $1.60 per joint compared to $0.50 per joint with automated systems, generating monthly savings exceeding $16,000, the financial argument became difficult to ignore. Payback periods of just 3 to 6 months make these investments accessible even for mid-sized operations. For an industry defined by tight margins and complex compliance requirements, automation is not a luxury; it is the clearest path to competitive viability.

The market forces behind this shift and the specific challenges producers face without automation reveal why adoption is accelerating across every segment of the supply chain.

What Market Forces Are Driving Cannabis Automation Adoption?

The primary market forces driving cannabis automation adoption are surging sales volume, expanding legalization, rising labor costs, and the operational complexity of indoor growing. Legal marijuana sales have climbed steadily as new state markets open, and the CBD oil market has added further demand across product categories.

Indoor growing introduces complex environmental variables, including precise temperature, humidity, and light control, that multiply the number of decisions producers must make each day. When managed manually, these variables become bottlenecks that limit throughput and increase error rates. Labor costs compound the problem; as the workforce struggles to keep pace with demand, every hour spent on repetitive manual tasks represents margin lost to inefficiency.

As reported by mg Magazine in its coverage of next-generation pre-roll automation solutions, producers are increasingly turning to automated systems to bridge the gap between what their teams can do and what the market requires. This convergence of rising demand, regulatory complexity, and workforce constraints makes automation adoption less of a strategic choice and more of an operational necessity.

What Challenges Do Cannabis Producers Face Without Automation?

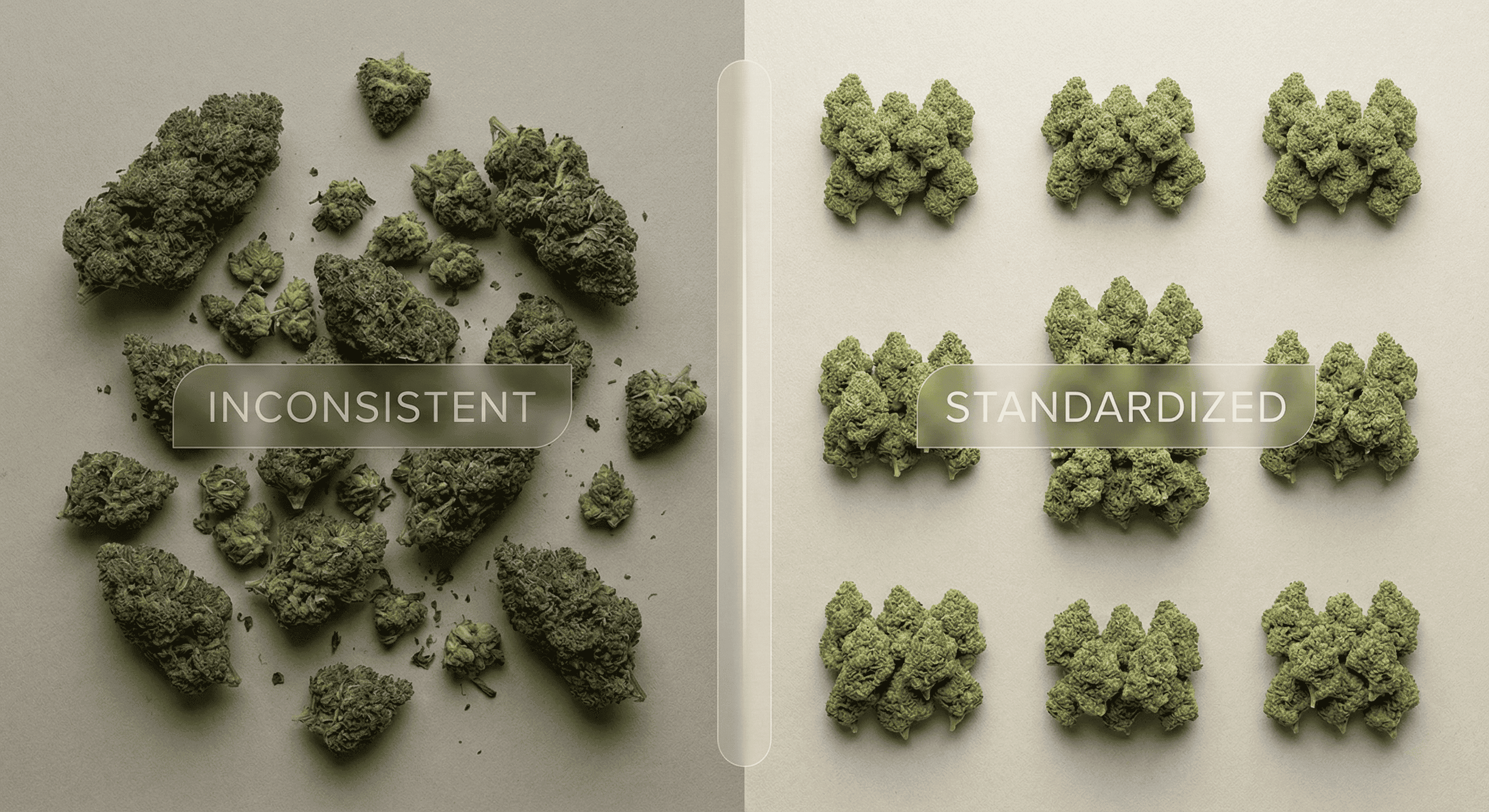

Cannabis growers face various operational challenges without automation, including crop waste, quality control failures, production bottlenecks, and safety hazards. Manual processes expose operations to human error at every stage, from cultivation through extraction and packaging.

Without automated environmental monitoring, conditions that promote mold, powdery mildew, and pests can go undetected until significant crop damage has occurred. The quality of product directly affects value and reputation, yet hand-managed workflows make consistency nearly impossible to maintain at scale. Key pain points include:

Crop waste from inconsistent handling: Overfilling, underfilling, and improper packing increase material loss.

Quality control gaps: Human inspection misses defects that automated vision systems catch reliably.

Production bottlenecks: Manual packaging systems create chokepoints that limit daily output.

Safety hazards in extraction: Workers handling solvents and operating pressurized equipment face injury risk that closed-loop automated systems eliminate.

Each of these challenges compounds as operations scale, turning manageable inefficiencies into serious financial liabilities. The sections that follow examine exactly how automation addresses these pain points, starting with cultivation and moving through every stage of the production lifecycle.

How Does Cultivation Automation Improve Growing Conditions?

Cultivation automation allows for precise control over environmental factors that directly determine plant health, cannabinoid production, and yield consistency. Intelligent software can be utilized in every aspect of a grow operation, from light spectrum management to nutrient delivery. By coordinating lighting, climate, fertigation, and ventilation into a unified system, automated cultivation removes the guesswork that leads to crop loss and inconsistent harvests.

The subsections below break down each core technology: LED lighting systems, HVAC and CO2 climate control, automated fertigation, and ventilation.

How Do Automated LED Lighting Systems Optimize Cannabis Growth?

LED lights give growers power to control light spectrum, intensity, and photoperiod with precision that manual systems cannot match. Spectral tuning adjusts the ratio of red, blue, UV, and IR wavelengths to match each cannabis growth stage. During vegetative growth, higher blue-spectrum output promotes compact, healthy foliage. In the flowering stage, UV and IR supercharge trichome and resin production.

Key capabilities of automated LED lighting include:

Dimming schedules that ramp intensity gradually, mimicking natural sunrise and sunset cycles.

Lighting scheduling that adjusts photoperiod automatically as plants transition between growth stages.

Samsung LM301H LEDs, which deliver high photosynthetic photon efficacy for maximizing photosynthesis per watt consumed.

Light schedule and intensity adjust to each cannabis growth stage without manual intervention. For most indoor cultivators, automated LED control is the single highest-impact upgrade because light is the primary driver of photosynthesis and, ultimately, flower quality.

How Do HVAC and CO2 Systems Automate Climate Control?

Integrated HVAC and CO2 systems can be automated to maintain optimal airflow, temperature, humidity, and CO2 levels throughout the grow cycle. CO2 levels trigger photosynthesis in plants; when concentration drops below the 800 to 1,200 ppm target range, automated sensors detect the deviation and signal supplemental CO2 injection.

According to the Resource Innovation Institute's 2021 Automation and Controls for Cannabis Cultivation best practices guide, integrated control of HVAC, lighting, and water management systems can reduce operating costs by 15% over traditional manual approaches. The same guide found that active energy management practices offer systematic structures that can generate savings of up to 30%.

IoT technology allows remote monitoring of grow room conditions through cloud-based dashboards. A 2024 study published in SoftwareX described SmartGrow DataControl, an IoT architecture that combines wireless sensors with open-source databases using standardized protocols including TCP/IP, MQTT, HTTP, and Web Socket to monitor temperature, humidity, CO2 levels, and light intensity in cannabis cultivations.

Automated sensors detect deviations in environmental conditions and trigger corrective responses in seconds, not hours. Real-time monitoring eliminates the lag between a climate fluctuation and a human operator noticing it. For operations scaling beyond a single room, this level of responsiveness is not a luxury; it is a prerequisite for consistent canopy conditions.

What Role Does Automated Fertigation Play in Cannabis Cultivation?

Fertigation is the application of fertilizers directly into the irrigation network, delivering nutrients and water simultaneously to each plant. An automated fertigation system uses wireless sensors to determine temperature, electrical conductivity (EC), and moisture level at the root zone in real time.

Based on these readings, the system adjusts nutrient concentration and irrigation volume without manual mixing or guesswork. Automated fertigation integrates into the broader environmental control system, coordinating nutrient delivery with lighting schedules and climate conditions. When light intensity increases, for example, water uptake rises, and the fertigation system compensates automatically.

This closed-loop approach eliminates the inconsistency of hand-mixing nutrients and reduces both overfeeding waste and underfeeding stress.

How Does Automated Ventilation Strengthen Cannabis Plants?

Automated airflow strengthens plant stems by simulating natural wind stress, which encourages thicker, more resilient stalks capable of supporting heavy flower clusters. Beyond structural benefits, automated ventilation reduces instances of mold and powdery mildew by preventing stagnant microclimates where moisture accumulates on leaf surfaces.

Consistent air circulation also keeps pests from establishing, since many common cannabis pests thrive in still, humid conditions. Automated airflow facilitates temperature and humidity homeostasis across the entire canopy, eliminating hot spots near lights and cold zones near walls.

Ventilation is often overlooked compared to lighting or climate control, yet it is the connective tissue that makes every other environmental system perform at its best. With cultivation conditions optimized across light, climate, nutrients, and airflow, the next critical phase is determining exactly when to harvest for peak potency.

What Cannabis Harvesting Processes Can Be Automated?

Cannabis harvesting processes that can be automated include maturity detection, harvest timing, trimming, and bucking. Trichomes turn from clear to milky or cloudy as cannabis flower matures, and vision systems can be programmed to detect these indicators of maturity with far greater precision than the human eye. A patented machine learning algorithm now sees cannabis at a level of detail that cultivators cannot match through visual inspection alone.

Cannabis cultivators should not rely solely on traditional methods to harvest. Computer vision and machine learning have introduced objective, data-driven approaches that remove guesswork from the harvest window, while robotic flower trimmers handle the labor-intensive work of separating usable flower from plant material. Together, these technologies bridge the gap between cultivation and post-harvest processing.

How Do Vision Systems Detect Optimal Harvest Timing?

A computer vision system analyzes trichome maturity by capturing high-resolution images of cannabis flower surfaces and measuring color, opacity, and structural changes at the microscopic level. A global cannabis dataset trains machine learning models to recognize the precise visual signatures that correlate with peak cannabinoid and terpene content.

Rather than relying on a single grower's experience or a magnifying loupe, these AI-powered systems evaluate thousands of data points per plant. AI technology replaces subjective human harvest assessment with consistent, repeatable analysis. When trichomes shift from transparent to the optimal milky-white stage, the system flags the plant for harvest. This integrated workflow, where computer vision feeds directly into harvest timing decisions, ensures cultivators capture peak potency instead of harvesting too early or too late.

For operations running multiple cultivars with different maturation rates, this kind of automated detection is particularly valuable because it eliminates the bottleneck of having a single expert evaluate every plant manually.

What Does Automated Trimming Look Like in Practice?

Automated trimmers feature AI technology that scans the entire cannabis plant to distinguish flower from leaf, stem, and stalk. AI technology guarantees precision trimming by mapping each bud's geometry before any blade engages, minimizing waste and maximizing yield from every plant.

Bucking is the process of removing leaves, stalks, and stems from flower, and automated systems handle this step at the front of the trimming line. Once bucked, cannabis moves into robotic flower trimmers that combine precision, speed, and consistency. According to a 2024 analysis of robotic trimming efficiency, robotic systems process hundreds of pounds per hour, while manual trimmers handle only 2 to 3 pounds per shift.

This throughput difference matters for both craft growers and large-scale producers. Craft operations benefit from precision trimming that preserves trichome-rich surfaces, while large-scale facilities gain the volume needed to meet market demand without expanding headcount. Automated trimming machines deliver the same cut quality on the thousandth pound as they do on the first, which is something no manual team can sustain across a full harvest cycle.

Once trimming is complete, cannabis flower moves into post-harvest processing, where automated drying, curing, and extraction systems take over to preserve the quality established during harvest.

How Is Post-Harvest Cannabis Processing Automated?

Post-harvest automation covers every stage from drying through extraction, including material handling and biomass management. These processes accumulate significant labor costs when performed manually, since each step requires careful environmental monitoring, precise timing, and repetitive physical work. Automating drying, curing, extraction, and material handling reduces human error while preserving the quality of cannabis flower at scale.

The subsections below break down how each post-harvest stage benefits from automation, starting with drying and curing before moving into extraction safety and material handling.

How Do Automated Drying Systems Preserve Cannabis Quality?

Automated drying systems create a controlled environment with precise regulation of temperature, humidity, and airflow. The initial drying process takes about a week, during which even minor fluctuations can degrade terpenes or promote mold growth. Manual monitoring struggles to maintain the narrow environmental windows that premium cannabis flower demands.

Automated systems offer precise control over these environmental factors through IoT-connected sensors that track conditions continuously. When temperature or humidity drifts outside target ranges, the system triggers corrective adjustments without human intervention. This level of responsiveness protects volatile terpene profiles that would otherwise be lost to excess heat or uneven airflow. For operations processing large volumes, the ability to monitor storage conditions across multiple drying rooms simultaneously eliminates the inconsistency that comes with manual spot-checks.

What Does Automated Curing Involve?

Automated curing uses sensors to monitor moisture content throughout a process that takes an additional several weeks after initial drying. Curing directly influences flavor and potency, making consistency at this stage critical for product quality.

Automation ensures consistency at all stages of curing by maintaining steady environmental parameters that manual processes cannot replicate over multi-week timelines. Sensors detect when moisture levels inside containers reach target ranges, triggering ventilation cycles or sealing adjustments automatically. Without this precision, batches within the same harvest can develop uneven potency or off-flavors. For producers managing dozens or hundreds of curing containers, automated monitoring replaces the guesswork of manual "burping" schedules with data-driven decisions that protect product value.

How Does Extraction Automation Improve Safety and Efficiency?

Extraction automation improves safety by removing human workers from the danger zone and improves efficiency through precise control over critical process parameters. CBD can be extracted by ethanol, CO2, or oil extraction methods, while closed-loop hydrocarbon extraction utilizes an extractor vessel closed to the outside atmosphere with solvents like butane and propane. Each method carries distinct risks that automated controls help mitigate.

Automated controls reduce operator error and remove the need for mechanical valves that require manual operation near volatile solvents. This is the strongest safety argument in cannabis automation: when workers interact directly with pressurized hydrocarbon systems, a single mistake can cause explosions or toxic exposure.

Automated extraction systems also maximize throughput. According to 2024 product specifications from Luna Technologies, fully automated BHO extraction systems can process up to 700 lbs of fresh-frozen material per day. For CO2 extraction, the extraktLAB e-180 supercritical CO2 extractor offers a capacity of 180 liters, positioning it among the highest-throughput CO2 systems available.

Luna Technologies BHO

Method: Hydrocarbon (BHO)

Daily Capacity: 700 lbs fresh-frozen material

extraktLAB e-180

Method: Supercritical CO2

Daily Capacity: 180 liters

The gap between these two approaches reflects a fundamental trade-off: BHO systems deliver higher raw throughput, while supercritical CO2 extraction avoids residual solvent concerns entirely. For most producers, the choice depends on target product type and risk tolerance rather than pure volume.

What Material Handling Processes Can Be Automated?

Automated systems handle grinding, de-seeding, and pelletizing of hemp biomass after primary processing is complete. These steps prepare raw material for secondary product lines and reduce waste across the operation.

Leftover stalks, seeds, and leaves can be transformed into biofuel, fiber products, and oils rather than being discarded. Automated biomass management reduces waste by sorting and processing these byproducts at speeds that make secondary revenue streams economically viable. Without automation, the labor cost of manually separating and processing residual plant material often exceeds the value of the resulting products, leaving usable biomass on the cutting room floor.

From drying and curing through extraction and material handling, post-harvest automation addresses the most labor-intensive and quality-sensitive stages of cannabis production. The next phase of the production lifecycle, pre-roll manufacturing, builds directly on these processed inputs.

How Does Automation Transform Pre-Roll Production?

Automation transforms pre-roll production by minimizing labor costs, maximizing output, and ensuring consistent quality across every cone size and product type. The financial impact is substantial. According to a 2025 RollPros analysis on pre-roll automation ROI, manual production costs $1.60 per joint with 500 daily output and 10% waste, while automated production costs $0.50 per joint with 3,000 daily output and only 2% waste. That comparison translates to monthly savings exceeding $16,000, giving a $75,000 machine a payback period under 5 months.

Labor remains one of the most expensive line items in cannabis production. A single trained machine operator can replace multiple manual workers, reducing payroll by tens of thousands of dollars annually. High-output pre-roll machines consistently produce more than 3,000 joints per day, compared to 300 to 500 for even a skilled manual team, according to the same RollPros report. For producers navigating price compression, this efficiency gap is no longer optional to close.

The subsections below cover the specific equipment stages: cone making and filling, infusion and specialty processes, and robotic packing that finishes each pre-roll for retail.

What Equipment Automates Cone Making and Filling?

The equipment that automates cone making and filling includes auto preform cone makers and dedicated cone filling systems. An auto preform cone maker cuts and forms cones directly from paper reels and card reels, eliminating the need to purchase pre-made cones. Systems like the AutoCone produce pre-rolled cannabis joints at scale with repeatable precision. For operations with tighter budgets, the AutoCone Lite has a lower capital outlay compared to standard automated pre-roll technology while still handling consistent cone filling. Once formed, pre-made cones are filled with cannabis using vibratory or tamping mechanisms that pack each unit to a target weight. This two-stage workflow, forming then filling, allows producers to handle a variety of cone sizes without manual intervention.

How Are Pre-Roll Infusion and Specialty Processes Automated?

Pre-roll infusion and specialty processes are automated through dedicated machines that eliminate the variability of hand processes for hash holes, donut joints, and kief-coated products. This is the fastest-growing segment in pre-rolls; according to a 2025 Sorting Robotics analysis on rosin and hash hole infusion, the infused pre-roll category is climbing toward 20% of market share, with demand growing 15% annually. A 2024 consumer survey cited in the same report found that 65% of consumers prefer infused pre-rolls for potency.

Manual hash hole production is costly and slow. Each joint takes 5 to 10 minutes by hand, with 30 to 40% concentrate waste from inconsistent placement. According to the same 2025 Sorting Robotics report, manual hash hole production costs average $5 per joint, while automated systems reduce this to $0.10 per joint. A case study of Blenz Cannabis demonstrated that scaling hash hole production from 5,000 to 20,000 units monthly using automation saved $15,000 in labor costs and increased revenue by 18%.

Automated systems also apply consistent kief coating to pre-rolls. Kief coating robots create kief-coated products with repeatable precision, using kief glue to bond the outer layer evenly across joints and blunts. Consistency improvements from automation are measurable; the 2025 Sorting Robotics report found a 25% improvement in customer satisfaction when producers switched to automated production. For any operation producing infused or specialty pre-rolls at volume, automation is the only realistic path to margin-positive scaling.

How Do Robotic Packing Machines Finish Pre-Roll Production?

Robotic packing machines place finished pre-rolls into packaging formats such as Kush Tubes, trays, pouches, childproof bags, and jars. Before packing, systems like the Autotwist Pre Roll Finishing automatically twist-finish filled pre-rolls, sealing the open end without manual handling. This final stage connects directly to downstream packaging lines, where sealed pre-rolls move into labeled, compliance-ready containers. By automating this last step, producers eliminate a common manual bottleneck and maintain the consistency established throughout the filling and infusion stages.

With pre-roll production fully automated from cone forming through packing, the next logical step is broader cannabis packaging and filling automation across all product types.

What Cannabis Packaging and Filling Processes Can Be Automated?

Cannabis packaging and filling automation covers weighing, bag filling, jar filling, cartridge filling, tax stamping, labelling, wrapping, cartoning, and overwrapping. Automated systems handle various product formats and packaging types, from flower jars to vape cartridges to edible pouches. Manual packaging systems create bottlenecks that slow production and introduce inconsistency, while robotic packaging solutions streamline operations and enhance brand image through uniform presentation.

According to a 2024 Global Market Insights report, the global cannabis packaging market was valued at USD 2.2 billion in 2024 and is estimated to grow at a CAGR of 17.4% from 2025 to 2034. This growth reflects surging demand for compliant, branded packaging at scale. A 2024 Paxiom article on automated cannabis packaging noted that pre-roll machines produce thousands of perfect joints per hour, and multi-head weigh fillers measure product to within one-tenth of a gram.

For operators still relying on hand-packing, these precision benchmarks are difficult to match without significant labor overhead. Packaging automation is where production speed meets shelf-ready presentation, and the subsections below break down the core systems involved.

How Do Automated Weighing and Batching Systems Work?

The Green Vault Systems Precision Batcher weighs out batches, checks finished batch weight, and dispenses product into packages in a single automated workflow. This type of precision batcher ensures product weight compliance by verifying each unit before it moves downstream.

According to a 2024 Paxiom report, many cannabis check weighers use EMFR (electromagnetic force restoration) technology, which relies on precise electronic measurements unaffected by external influences. This makes EMFR-equipped systems significantly more accurate at tiny weight tolerances than conventional load-cell alternatives. For operations managing dozens of SKUs across flower, edibles, and concentrates, automated weighing and batching eliminates the manual bottleneck where compliance violations most often occur.

How Does Cartridge Filling Automation Improve Throughput?

Cartridge filling machines ensure precise fill volumes for cannabis oil and vape products, eliminating the underfills and overfills common in manual workflows. Cartridge filling integrates with extraction output, creating an end-to-end workflow from concentrate production to finished vape cartridge.

According to a 2024 Paxiom overview of packaging advancements, complete automation lines handle the entire process from start to finish: flowers can be weighed, bottled or bagged, sealed, capped, labeled, and case packed. The same principle applies to cartridge filling, where automated systems meter exact volumes of cannabis oil into hundreds or thousands of cartridges per hour. This connection between extraction and cartridge filling is often overlooked, but it represents one of the highest-throughput opportunities in cannabis packaging. When extraction runs faster than your filling line can package, revenue sits idle.

What Tax Stamping and Labelling Automation Is Available?

Automated tax stampers attach tax stamps in various positions on cannabis packaging. A typical tax stamper produces 100 packs per minute and uses hot melt or PVA glue, depending on the substrate and regulatory requirement. Automated labelling systems apply wraparound, top, or bottom labels to bottles, jars, cans, and containers at comparable speeds.

In regulated markets where every unit requires a tax stamp and compliant label, manual application is one of the slowest tasks on the packaging line. Automating these steps removes a persistent compliance risk while maintaining the throughput established upstream in weighing and filling. Together, these packaging subsystems connect directly to the broader compliance and data management requirements that automated tracking platforms enforce across the production lifecycle.

What Are the Core Benefits of Cannabis Automation?

The core benefits of cannabis automation span four critical areas: consistency and quality control, labor cost reduction, worker safety, and scalability. Automation combines data from multiple sources, analyzes operational variables in real time, and presents actionable insights that drive measurable improvements across the production lifecycle.

While earlier sections explored what can be automated at each stage, this section consolidates why these investments matter. Each benefit reinforces the others; consistent quality reduces waste, lower labor costs free capital for expansion, safer environments reduce liability, and scalable systems support long-term growth.

How Does Automation Ensure Consistency and Quality Control?

Automation guarantees consistent growth and quality by removing subjective human judgment from critical inspection points. Automated processes ensure each plant receives the same level of care, while automated sensors detect deviations and trigger corrective actions before defects compound.

Vision-based quality control represents the most significant advancement in this area. According to a 2024 article from Twister Trimmer on automated grading in cannabis, advanced AI vision systems inspect every square millimeter of cannabis flower for quality metrics such as trichome density, color, size, and potential defects. This level of granularity is impossible to sustain manually. Automated processes minimize the risk of impurities and inconsistencies by applying identical standards to every unit, whether the run produces 100 or 100,000 items.

Real-time monitoring through sensors creates a continuous feedback loop. When environmental or product parameters drift outside acceptable ranges, corrective actions engage immediately rather than after a batch is compromised. For any operation where brand reputation depends on product uniformity, automated quality control is the single most impactful investment.

How Does Automation Reduce Labor Costs and Increase Efficiency?

Automation reduces labor costs and maximizes efficiency by replacing repetitive manual tasks with precise, high-throughput machinery. Automation minimizes human error, reduces the need for manual labor, and helps reduce waste across every production stage.

According to a 2025 analysis from RollPros on pre-roll automation ROI, high-output automated machines consistently produce more than 3,000 joints per day, compared to 300 to 500 for a skilled manual team. Replacing multiple manual workers with a single trained machine operator can reduce payroll costs by tens of thousands of dollars annually.

Production automation also helps reduce waste. Hand-processed products often vary in weight, fill level, or infusion placement, resulting in material loss and compliance risk. Automated systems eliminate this variability, producing uniform output with minimal product loss. For operations under price compression, the efficiency gains from automation often represent the difference between profitability and margin erosion.

How Does Automation Improve Worker Safety?

Automation reduces risks by removing human workers from hazardous processes. Machines, robots, and closed-loop systems manage chemical handling, solvent exposure, and other dangerous tasks that would otherwise require direct human contact.

Automated extraction systems provide the clearest example. Closed-loop hydrocarbon extraction involves volatile solvents such as butane and propane. An automated extraction system removes human workers from the danger zone by controlling pressure, temperature, and solvent flow through programmed sequences rather than manual valve adjustments. Automated systems also detect potential safety hazards, including gas leaks, pressure anomalies, and temperature spikes, and respond to them before conditions become dangerous.

Beyond extraction, safety hazard detection extends to cultivation environments where chemical handling for pest control and nutrient management poses respiratory and dermal risks. Automating these processes is not just an operational improvement; it is a liability reduction strategy that protects both workers and the business.

How Does Automation Enable Scalable Cannabis Operations?

Automation enables scalability for both craft growers and large-scale producers by decoupling production capacity from headcount. Companies can expand systems incrementally or modify configurations to match demand without proportional labor increases.

Bespoke machinery and factory layout planning allow operations to maximize use of available factory space while building in room for production expansion. A craft operation producing 5,000 units monthly can scale to 20,000 or more by adding modular automated equipment rather than tripling its workforce. This flexibility applies across cultivation, processing, and packaging.

Thoughtful layout planning also matters. Facilities designed around automated workflows minimize material handling distances, reduce bottlenecks, and create clear pathways for future equipment additions. For any cannabis business planning beyond its current volume, investing in automation architecture now prevents costly facility redesigns later.

With consistency, cost efficiency, safety, and scalability established as the foundational advantages, the next section examines how automation supports the compliance and data management requirements that regulate every aspect of licensed cannabis operations.

How Does Automation Support Cannabis Compliance and Data Management?

Automation supports cannabis compliance and data management by tracking cultivation conditions, recording chemical inputs, and integrating with seed-to-sale reporting systems to minimize human error. Regulatory compliance is a cornerstone of legal cannabis operations, and automated compliance management is essential for meeting state requirements while maintaining operational integrity. Because each state enforces distinct regulatory standards, automated systems provide the record-keeping consistency that manual processes cannot reliably deliver.

Seed-to-sale tracking platforms like Metrc serve as compliance reporting tools, enabling licensed businesses to track plant actions, inventory movements, and sales data for regulatory purposes. According to Metrc, integration of inventory management systems with their platform ensures both compliance and seamless inventory control, while businesses can leverage that data alongside external systems for production planning, demand forecasting, and fulfillment strategies. Automated data collection reduces compliance risk by minimizing human error in data entry and documentation, which directly supports auditing and reporting requirements.

Beyond digital tracking, physical compliance measures also benefit from automation. Modern packaging systems include sensors that detect and reject containers with missing or inadequate tamper-evident seals, according to a 2024 Paxiom report on automated cannabis packaging advancements. This combination of digital record-keeping and physical quality verification creates a comprehensive compliance framework. For operators navigating complex regulatory environments, investing in compliance automation is not optional; it is the most reliable way to protect licenses and avoid costly violations.

What Data Do Automated Systems Track for Regulatory Purposes?

Automated systems track pesticide usage, water quality, cultivation conditions, and pest control measures across the entire cannabis lifecycle. Metrc's seed-to-sale tracking system monitors every stage, from mother plants and cloning through vegetative and flowering phases, harvesting, processing, packaging, and final consumer sale. By maintaining compliant records at each stage, businesses keep inventory traceable from seed to sale.

A comprehensive data trail satisfies regulatory audits because automation combines data from multiple sources into a single, verifiable record. Key data points tracked for regulatory purposes include:

Pesticide application types, volumes, and timing

Water quality metrics and irrigation records

Environmental conditions such as temperature, humidity, and CO2 levels

Pest control measures and integrated pest management actions

Inventory movements and chain-of-custody transfers

This level of granular documentation would be nearly impossible to maintain accurately through manual record-keeping alone, which is precisely why regulators increasingly expect digital tracking infrastructure.

How Does Automated Testing Verify Product Quality and Potency?

Automated testing helps producers verify the quality, potency, and purity of cannabis products before they reach consumers. Cannabis consumers search for high-quality products, and automation ensures consistency at all stages of production, from flower grading through final packaging inspection.

Advanced vision systems represent one of the most impactful testing innovations. According to a 2024 Twister Trimmer report, automated sorting systems operate up to 100 times faster than manual sorting while inspecting every square millimeter of cannabis flower for quality metrics like trichome density, color, size, and defects. This speed advantage is critical for producers scaling output without sacrificing product standards.

Automated quality verification extends beyond visual inspection to weight validation, potency testing integration, and contamination screening. When these systems flag inconsistencies, corrective actions happen immediately rather than after an entire batch has been compromised. For any operation prioritizing consumer trust, automated testing is the quality verification endpoint that connects production consistency to regulatory compliance.

What Technologies Power Cannabis Automation Systems?

Cannabis automation systems are powered by a convergence of IoT, AI, computer vision, machine learning, PLCs, and cloud-based controls. Industry 4.0 integrates IoT with advanced communications protocols to create connected ecosystems where sensors, controllers, and analytics platforms share data seamlessly. Computer vision powers precision detection and analysis across cultivation, harvesting, and quality control workflows. Machine learning improves system accuracy over time by training on operational datasets that grow with each production cycle.

These technologies work in layers. PLCs execute real-time automation commands on the facility floor, while cloud-based controls aggregate data for remote oversight and long-term optimization. Understanding how each layer functions reveals why modern cannabis operations can achieve levels of precision and consistency that manual processes cannot match.

How Do IoT and Cloud-Based Controls Enable Remote Management?

IoT technology provides cannabis operators with real-time insight and control over every connected system in their facility. Wireless sensors feed real-time data to centralized dashboards, covering variables such as temperature, humidity, CO2 levels, light intensity, and nutrient delivery. This data streamlines decision-making by consolidating environmental readings into a single interface accessible from any location.

A 2024 academic study published in SoftwareX documented SmartGrow DataControl, an IoT architecture designed specifically for monitoring environmental and physiological parameters in cannabis cultivation. The system combines wireless devices with open-source databases using standardized communication protocols, including TCP/IP, MQTT, HTTP, and Web Socket, to maximize energy efficiency and data reliability.

Cloud-based controls extend this capability beyond on-site monitoring. Operators can adjust setpoints, review historical trends, and receive alerts remotely, which is particularly valuable for multi-facility operations. For most cannabis producers, IoT represents the foundational technology layer; without it, higher-level tools like AI and machine learning have no data to work with.

How Are AI and Computer Vision Used in Cannabis Operations?

AI and computer vision supercharge cannabis production by replacing subjective human assessment with data-driven precision. Computer vision systems analyze cannabis flowers at a granular level, assessing quality metrics that include:

Trichome density and maturity stage

Color consistency across the canopy

Bud size and structural uniformity

Surface defects, mold indicators, or contamination

A patented machine learning algorithm trained on a global cannabis dataset enables these systems to "see" cannabis with increasing accuracy over each cycle. According to a 2024 analysis from Twister Trimmer, automated sorting systems powered by AI vision can operate up to 100 times faster than manual sorting while maintaining accuracy. PLCs execute the resulting automation commands in real time, translating AI decisions into physical actions on the production line.

Beyond quality control, AI and computer vision are reshaping how cannabis is produced at scale. These technologies are no longer experimental; they represent the operational standard that separates high-performing facilities from those still relying on manual inspection. Operators who integrate AI early gain compounding advantages as their machine learning models improve with each production run.

With these core technologies established, the next step is understanding how to evaluate and implement the right automation strategy for a specific cannabis operation.

How Should You Approach Cannabis Automation?

Cannabis automation solutions should be customized for your business, not adopted as one-size-fits-all packages. The right combination of equipment depends on your operation size, product mix, and growth goals. An automation assessment helps evaluate which processes will deliver the fastest ROI and which can wait.

For most cannabis operators, the smartest approach is to start with the highest-labor, highest-waste bottleneck in your production line and automate that first. Specialty processes like pre-roll infusion and hash hole production often represent the steepest labor cost differential between manual and automated methods, making them ideal starting points for operators in those categories.

Can Sorting Robotics Help With Cannabis Automation?

Sorting Robotics builds cannabis automation machines that specialize in specialty pre-roll and infusion automation. Sorting Robotics automates pre-roll infusion using Jiko, hash holes and donut making using Jiko+, cartridge filling using Omni, and kief coating for joints, blunts, and kief-coated products using MoonGlue & Stardust.

The results speak for themselves. According to a 2025 case study, the Blenz Cannabis operation scaled hash hole production from 5,000 to 20,000 units monthly using Sorting Robotics automation, saving $15,000 in labor costs and increasing revenue by 18%. The Jiko+ Donut Maker produces 800 pre-rolls per hour with 99.9% dosing accuracy, while reducing per-unit labor costs from $5 to $0.10 per hash hole.

These gains matter because infused pre-rolls are climbing toward 20% of market share with 15% annual growth, and 65% of consumers prefer infused pre-rolls for potency according to 2024 survey data.

Sorting Robotics offers an automation assessment to help cannabis businesses identify where bespoke machinery can deliver the greatest impact across their specific production workflow.

What Are the Key Takeaways About Cannabis Automation We Covered?

Cannabis automation spans the entire production lifecycle, from cultivation and harvesting through processing, pre-rolls, packaging, and compliance. The right automation combination depends on your operation's specific needs, but several core lessons apply across all scales:

Cultivation automation using IoT sensors, HVAC integration, and automated fertigation creates precise environmental control that reduces operating costs and improves crop consistency.

Harvesting and trimming automation replaces the most labor-intensive manual processes with AI-guided vision systems and robotic trimmers.

Post-harvest processing, including drying, curing, and extraction, benefits from closed-loop automation that improves both safety and yield.

Pre-roll production, particularly specialty infusion processes like hash holes and kief coating, offers some of the highest ROI opportunities due to extreme labor cost differentials.

Packaging and compliance automation ensures regulatory adherence through seed-to-sale tracking while eliminating bottlenecks in weighing, filling, and labeling.

Technologies like AI, computer vision, and cloud-based IoT platforms are accelerating what is possible at every stage.

The financial case for cannabis automation is compelling, with rapid payback periods and significant ongoing efficiency gains. As legalization expands and price compression intensifies, automation is no longer optional for competitive cannabis producers. Prioritize the processes with the highest labor costs and waste rates, invest in customized solutions that fit your operation, and scale from there.