Developing End-Of-Arm Tools & Accessories for Cannabis Robotics

The cannabis industry, a rapidly expanding sector in the global economy, is projected to surpass $134 billion in annual sales by 2030, according to the Grand View Research. This surge in demand has placed unprecedented pressure on manufacturers to produce at scale while preserving product quality and meeting stringent regulatory requirements. Automation technologies, particularly End-of-Arm Tooling (EOAT), have emerged as essential components in achieving these goals.

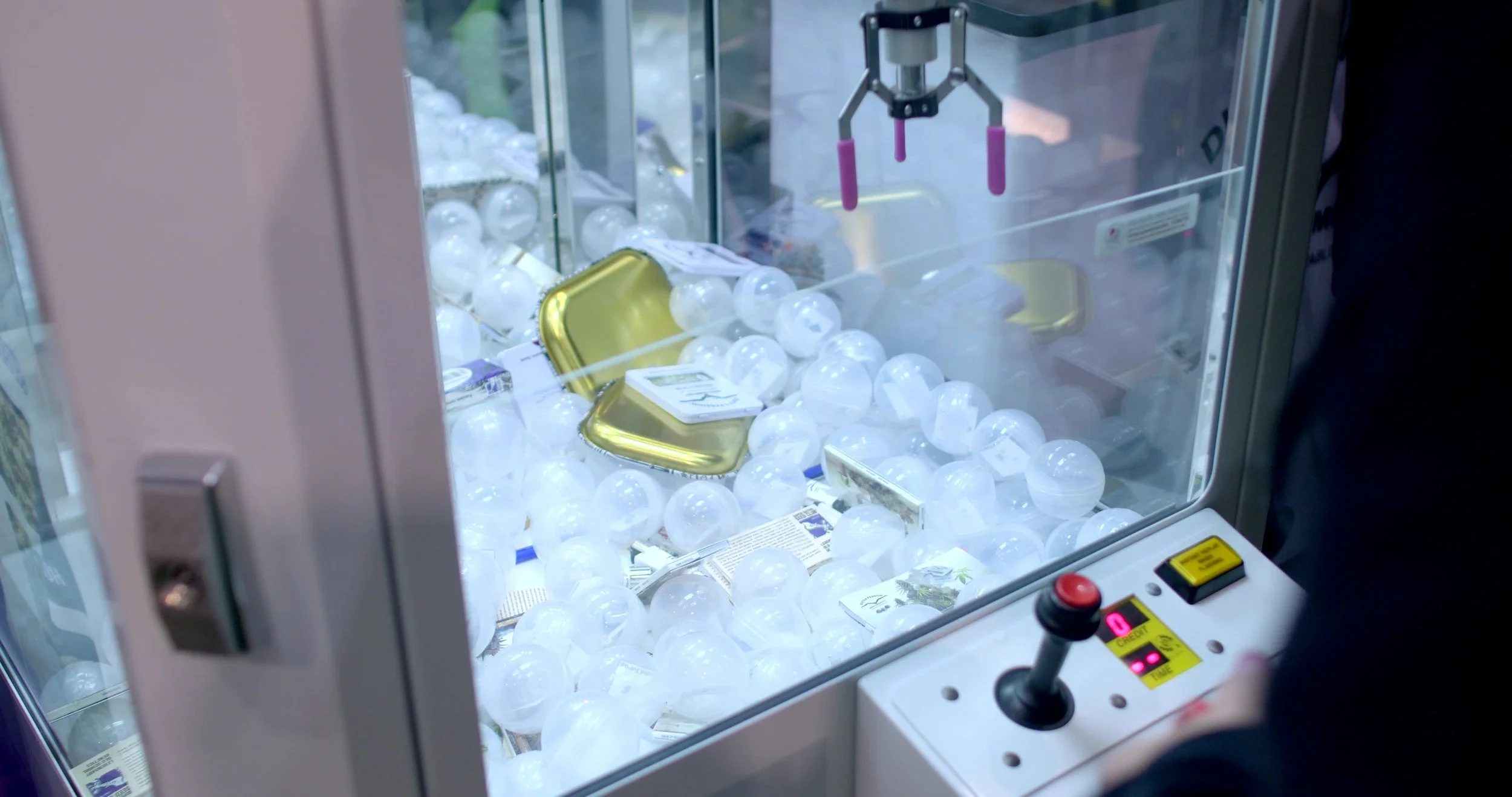

EOAT serves as the direct interface between robotic systems and cannabis products, enabling precise handling for tasks such as trimming, Stardust kief coating, pre-roll infusion, and packaging. By enhancing accuracy, reducing waste, and increasing throughput, these tools are redefining efficiency in cannabis manufacturing.

In this guide, we will examine the principles behind EOAT design, its most impactful applications in cannabis production, and the future innovations poised to shape the next generation of automated processing.

What is EOAT In Cannabis Robotics

End-of-Arm Tooling (EOAT) plays a crucial role in the success of cannabis robotics. It serves as the robotic arm's "hand," performing a wide range of tasks with precision and efficiency. EOAT includes devices such as grippers, cutting tools, and dispensing systems, designed to handle delicate cannabis products, including buds and pre-rolls.

EOAT enhances automation by improving precision, speed, and adaptability, which is vital for streamlining complex cannabis manufacturing processes.

How Does EOAT Improve Cannabis Manufacturing?

EOAT is essential for optimizing the efficiency of cannabis production lines. By using specialized grippers and dispensing systems, cannabis robots can handle sensitive materials without damaging them, ensuring a higher quality of output. This ability to automate previously manual tasks has been shown to reduce human error significantly, as robots can operate consistently and efficiently.

Custom robotics and automation for cannabis manufacturing is crucial because automation technologies, including robotics, have significantly lowered labor costs, increased production efficiency, and improved product consistency across cannabis cultivation and processing. These advancements have transformed previously manual operations, such as extraction and irrigation, into near-turnkey processes, enabling producers to scale operations, enhance profitability, and maintain product integrity in a competitive market.

Why EOAT Matters for Cannabis Production

Cannabis production involves delicate materials and stringent quality requirements, making generic EOAT unsuitable. Custom EOAT, as developed by Sorting Robotics, addresses challenges like:

Delicate Handling: Prevents damage to buds or trichomes during trimming or coating.

Precision: Ensures accurate dosing in infusion or consistent cutting in trimming.

Scalability: Supports high-throughput operations, reducing labor costs by up to 30%.

These capabilities make EOAT a linchpin for cannabis automation, enabling manufacturers to meet regulatory standards and consumer expectations.

Key Considerations in Developing EOAT for Cannabis Robotics

Designing End-of-Arm Tooling (EOAT) for cannabis robotics necessitates a comprehensive understanding of the unique demands within the cannabis production environment. The following factors are pivotal:

Application Requirements

EOAT must be tailored to the specific tasks within cannabis production:

Trimming: Utilize cutting tools with precise blades to ensure accurate weed removal or bud trimming.

Kief Coating: Employ grippers or applicators that facilitate uniform coating.

Infusion: Incorporate dispensing nozzles capable of injecting concentrates.

Material Characteristics

Cannabis materials exhibit variability in texture, weight, and fragility:

Shape: Buds and pre-rolls possess irregular shapes, necessitating adaptive grippers.

Material: Sticky trichomes or oily concentrates require non-stick coatings or vacuum grippers to prevent residue buildup.

Weight: Lightweight buds demand gentle handling, while heavier packages may require robust mechanical grippers.

Process Parameters

Cannabis processes necessitate specific speed, force, and precision:

High-Speed Operations: Lightweight EOAT is essential for rapid trimming or coating.

Precision Tasks: Sensors are crucial for accurate dosing or cutting.

Force Requirements: Designs must balance the need for robust cutting of tough stems with the gentle handling required for delicate buds.

Payload and Reach

EOAT must align with the robot's payload and reach:

Payload: The weight of EOAT, including grippers or blades, must remain within the robot's capacity to avoid overloading.

Reach: Designs should avoid singularity points, ensuring smooth operation in confined greenhouse spaces.

Environmental Factors

Cannabis production environments, such as greenhouses, present unique challenges:

Humidity: EOAT should utilize corrosion-resistant materials to withstand high humidity levels.

Residue: Non-stick surfaces are essential to prevent trichome or resin buildup, ensuring consistent performance.

Cleanliness: EOAT designs must minimize crevices to facilitate easy cleaning, adhering to regulatory standards.

Types of EOAT for Cannabis Robotics

End-of-Arm Tooling (EOAT) serves as the critical interface between robotic systems and cannabis production processes. The selection of appropriate EOAT components is essential for optimizing efficiency, precision, and adaptability in tasks such as trimming, coating, infusion, and packaging.

Grippers

Grippers are fundamental EOAT components designed to handle various cannabis products, each tailored to specific material properties and task requirements:

Vacuum Grippers: Utilize suction to securely handle flat or smooth cannabis packages, ensuring non-marring grips suitable for packaging finished pre-rolls.

Mechanical Grippers: Employ adaptive fingers to grasp irregularly shaped items like buds, providing secure handling during processes such as kief application.

Magnetic Grippers: Ideal for handling metal containers in packaging lines, offering enhanced speed and precision in operations.

Cutting Tools

Cutting tools are employed to perform precise trimming and processing of cannabis materials:

Blades: Specialized blades, such as S-shaped designs, are utilized for efficient weed removal or bud trimming, achieving high precision in cutting tasks.

Rotary Cutters: Feature adjustable speeds to accommodate various trimming requirements, ensuring consistent results in cannabis processing.

Dispensing Nozzles

Dispensing nozzles are crucial for the accurate application of substances in cannabis production:

Infusion Systems: Deliver precise doses of concentrates, ensuring uniform pre-roll infusion and maintaining product consistency.

Adhesive Applicators: Apply water-based adhesives evenly for kief coating, facilitating uniform application across products.

Sensor-Equipped EOAT

Integrating sensors into EOAT enhances the precision and adaptability of robotic systems:

Vision Sensors: Enable precise weed detection or bud positioning, facilitating accurate processing and minimizing errors.

Force Sensors: Ensure gentle handling of delicate materials, preventing damage during trimming or packaging processes.

The integration of sensors provides real-time feedback, enhancing the accuracy and adaptability of cannabis robotics systems.

Future Trends in Cannabis EOAT

Advancements in adaptive mechanisms, AI integration, sustainability, and modular design drive the evolution of End-of-Arm Tooling (EOAT) in cannabis robotics. These innovations aim to enhance precision, efficiency, and scalability in cannabis production processes.

Adaptive Grippers with Embedded Sensors

Adaptive grippers equipped with embedded sensors, such as magnetic or pressure sensors, are increasingly utilized in cannabis robotics. These grippers dynamically adjust their grip force and configuration based on the shape, size, and weight of the cannabis products, ensuring delicate handling and reducing product damage during tasks like trimming or packaging. Research indicates that soft robotic grippers, which can modulate their grip modes through embedded sensing and actuation mechanisms, enable gentle yet secure handling of irregular, flexible, and fragile items in unstructured environments.

AI and Vision Integration for Enhanced Precision

The integration of AI-driven EOAT systems with advanced vision technologies, including multi-dimensional (4D) vision, supports real-time detection and classification of cannabis materials such as buds and leaves. This enhances precision in sorting and handling within greenhouse or processing environments. Studies in agricultural robotics highlight the use of eye-in-hand sensing frameworks combined with AI for autonomous recognition and manipulation of crops in dense and complex vegetation, improving operational efficiency and reducing human intervention.

Sustainable and Energy-Efficient Design

Future EOAT solutions focus on sustainability by employing eco-friendly materials and energy-efficient actuators, aligning with industry goals for reducing environmental impact. Energy-saving features in robotic end effectors, including passive adaptive gripping mechanisms that consume power only during actuation, contribute to lowering operational energy requirements while maintaining performance.

Modular and Reconfigurable Systems

Modular EOAT platforms allow rapid reconfiguration to perform diverse tasks such as trimming, coating with kief or concentrates, and packaging. This flexibility enables manufacturers to adapt quickly to changing production demands and product variations without extensive equipment downtime or replacement. Recent developments in modular gripper design emphasize ease of customization and tool interchangeability to maximize operational versatility and throughput..

Ready to Innovate Your Cannabis Production?

End-of-Arm Tooling (EOAT) is revolutionizing cannabis production by automating delicate tasks such as trimming, coating, and infusion. The integration of adaptive grippers, AI-driven sensor systems, and modular designs enhances precision and scalability, while sustainable materials and energy-efficient actuators contribute to eco-friendly operations. These advancements not only streamline production but also ensure consistent product quality and compliance with industry standards.

Embrace the future of cannabis manufacturing by integrating custom EOAT solutions tailored to your specific needs. Contact Sorting Robotics today to explore how our innovative EOAT designs can enhance your production processes, improve product quality, and contribute to a more sustainable and efficient operation. Our team is dedicated to providing cutting-edge Robotics Manufacturing Services that align with the latest industry trends and technological advancements.

Frequently Asked Questions

What is End-Of-Arm Tooling (EOAT) in cannabis robotics?

EOAT refers to the specialized devices attached to the end of a robotic arm that allow it to interact with cannabis products and perform specific tasks such as gripping, cutting, or packaging. These tools can be grippers, cutters, dispensers, or multi-functional devices explicitly designed for soft, delicate, or irregularly shaped cannabis items.

How do I choose the right EOAT for cannabis robotics applications?

Selection depends on the specific task (e.g., picking, placing, trimming), the physical characteristics of cannabis products (size, shape, weight, and delicacy), the robot's payload capacity, and environmental factors like humidity or dust. Compatibility between the EOAT and the robotic arm is crucial to ensure smooth operation and safety.

Can EOATs be customized for unique cannabis processing needs?

Yes, EOATs can be custom-designed to handle the unique requirements of cannabis robotics, such as delicate handling of flower buds, trimming branches, or precise dosing for packaging. Custom tooling helps increase efficiency and protect product integrity during automated processes.

What types of EOAT power and control options are available for cannabis robotics?

EOATs can be powered and controlled electrically, pneumatically, or hydraulically. Pneumatic and electric grippers are common for tasks requiring variable force and delicate handling, especially important for cannabis products to avoid damage during manipulation.

How do EOATs improve the efficiency and quality of cannabis packaging?

EOATs enable precise, consistent handling and placement of cannabis products, reducing manual labor and packaging errors. They can handle soft, irregular shapes gently, maintain hygiene standards, and speed up the packaging process, ultimately improving throughput and reducing costs.