AI-Vision & Sensor System Consulting for Cannabis Sorting

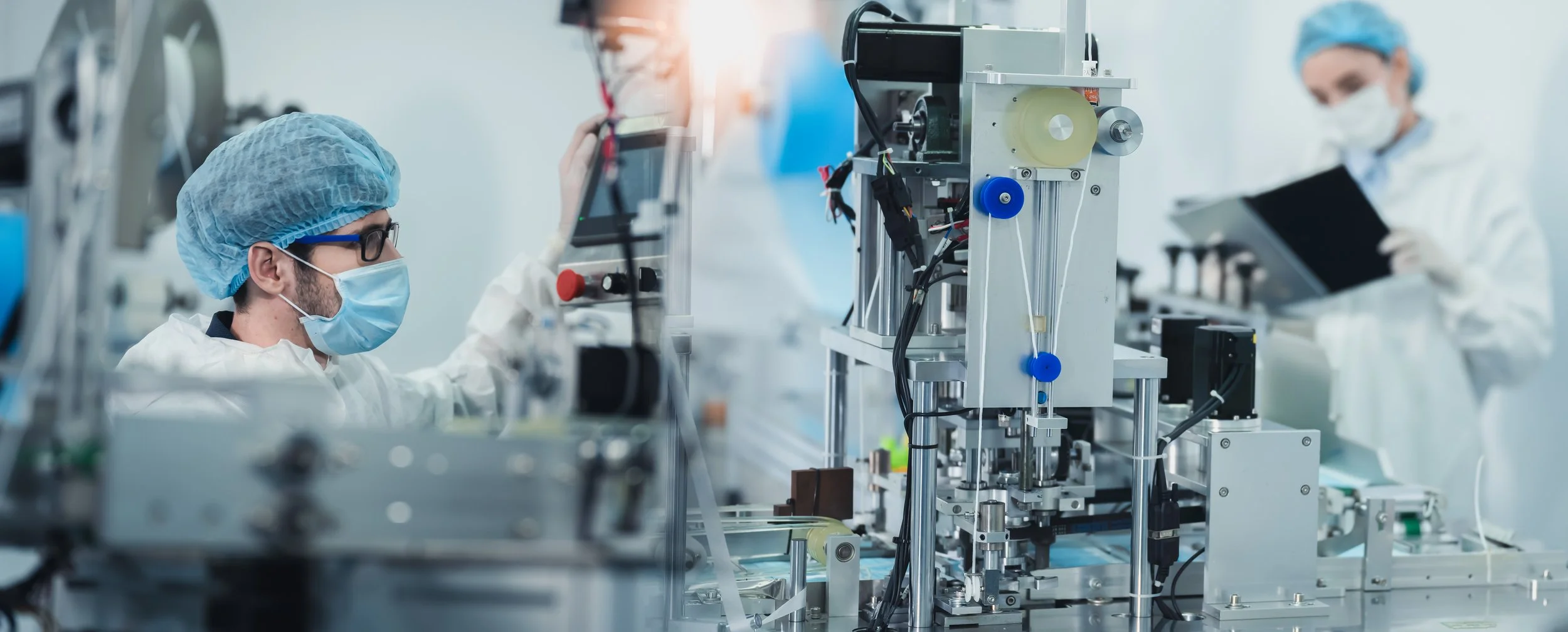

In the cannabis industry, product quality determines market reputation, regulatory compliance, and customer loyalty. AI-vision and sensor systems now play a key role in automating cannabis sorting, ensuring only the highest-quality buds reach consumers.

According to MarketsandMarkets (2024), the machine vision market in agriculture is projected to grow at a CAGR of about 8.3% from 2025 to 2030, rising from USD 15.83 billion to USD 23.63 billion, driven by demand for precision and consistency (source). For cannabis businesses, adopting AI-driven sorting technology isn't just about speed; it's about accuracy, compliance, and cost efficiency.

This article explains how expert consulting helps operators select, integrate, and optimize AI-vision and sensor systems for maximum ROI.

What Is AI-Vision & Sensor System Consulting in Cannabis?

AI-vision and sensor system consulting is the professional guidance cannabis operators receive to select, configure, and optimize camera- and sensor-based automation for product sorting.

AI-vision systems use high-resolution cameras, advanced optics, and machine learning algorithms to identify quality attributes in cannabis, such as bud size, color uniformity, and visible defects. Sensor systems enhance this by measuring properties invisible to the naked eye, such as moisture content or density.

Consultants bridge the gap between hardware capability and operational goals, ensuring the chosen system is both cannabis-specific and scalable.

The National Institute of Standards and Technology (NIST) notes that AI-vision systems can achieve up to 99% accuracy in defect detection in regulated agricultural sectors.

Why not buy an AI-vision system without consulting?

Because cannabis has unique morphology, trichome structures, and compliance thresholds that generic agricultural systems may not detect accurately. Without consulting, misaligned specs can lead to expensive misclassifications and wasted product.

Why AI-Vision Matters for Cannabis Sorting

AI-vision matters because it delivers consistency and efficiency far beyond human capability. A Journal of Food Engineering study found that AI-vision sorting reduced manual inspection labor by 70% in comparable agricultural processes.

In cannabis, even small variances in bud appearance or contaminant presence can affect perceived quality, potency labeling, and legal compliance. AI-vision prevents subjective errors, detects anomalies in milliseconds, and maintains uniform grading standards across large volumes.

How does AI-vision improve compliance in cannabis?

By enforcing precise grading rules and flagging defects, AI-vision reduces the risk of non-compliant products reaching packaging, avoiding potential recalls and fines.

How Sensor Systems Enhance Cannabis Sorting Accuracy

Sensor systems add quantitative precision to AI-vision's visual analysis. They can measure:

Moisture content (preventing mold risk)

Weight (ensuring accurate dosing in packaging)

Density (categorizing buds for premium or pre-roll product streams)

Spectral signatures (detecting contaminants invisible to human eyes)

The USDA Agricultural Research Service found that integrating multi-sensor data with vision systems increases decision accuracy by up to 20% in sorting applications.

In cannabis sorting, this dual-layer approach means each product is evaluated on both physical appearance and internal quality metrics, ensuring end-to-end consistency.

Which sensors are most valuable for cannabis sorting?

Moisture, weight, hyperspectral, and density sensors deliver the most significant impact because they directly influence quality, safety, and compliance.

Additional Types of Sensors for Cannabis Applications

Beyond the core sensors, cannabis sorting can also benefit from:

Near-infrared (NIR) spectroscopy detects chemical composition and residual solvents.

Thermal sensors identify improper curing by detecting uneven heat patterns.

3D laser profiling measures bud volume for packaging optimization.

These sensors expand the sorting criteria, enabling premium segmentation and process optimization.

Key Benefits of AI-Vision & Sensor Consulting in Cannabis

Consultants provide value by aligning system capability with business outcomes:

Benefits, Operational Impact & Examples

| Benefit | Impact on Operations | Example |

|---|---|---|

| Improved product consistency | Uniform grading standards | 90%+ of buds meet premium criteria |

| Waste reduction | Fewer rejections post-packaging | Defect detection pre-processing |

| Higher throughput | 2–3× manual speed | 400+ lbs/day sorted |

| Compliance assurance | Detect contaminants early | Mold detection before curing |

| Scalability | Modular system upgrades | Add sensors as volume grows |

The Automation Federation reports that professional integration planning can increase ROI by 30–40% compared to ad-hoc adoption, similar to scale vape output without growing team strategies..

Can consulting really impact long-term ROI?

Yes, optimal calibration and integration reduce downtime, lower error rates, and extend equipment lifespan, increasing return over multiple harvest cycles.

The Consulting Process for AI-Vision & Sensor Systems

Consulting ensures systems aren't just purchased. They're deployed to their maximum potential.

Typical Process:

Operational audit: Map current sorting workflow, defect types, and volume.

Technology recommendation: Identify AI-vision models, sensor types, and specifications.

Integration blueprint: Plan conveyor speed, lighting control, and data integration.

Pilot deployment: Test under real production conditions.

Performance tuning: Adjust detection thresholds and data triggers.

Staff training: Ensure operators can maintain calibration and handle data outputs.

The International Society of Automation confirms that structured commissioning reduces integration errors by over 50%, paralleling findings in fast track training tips for new vape filling operators about training’s impact on ROI..

How long does consulting typically take?

Between 2–6 weeks, depending on facility complexity, volume, and system sophistication.

Challenges in Cannabis AI- Vision & Sensor Implementation

Common hurdles include:

Lighting variability: inconsistent brightness can skew detection accuracy.

Product morphology differences: strain-specific bud traits require retraining models.

Sensor drift: gradual deviation in readings needs preventive recalibration.

Data overload: operators must filter out irrelevant metrics from meaningful ones.

MIT CSAIL found that uncontrolled lighting can reduce AI-vision accuracy by up to 15%.

How do consultants solve lighting and calibration issues?

By designing fixed-illumination environments, scheduling routine calibrations, and implementing automated self-check protocols in the software.

Calculating ROI for AI-Vision & Sensor Systems in Cannabis

ROI depends on:

Labor hours replaced.

Waste reduction in grams per batch.

Downgrade rate reduction (premium vs. trim).

Throughput increases.

Example:

System cost: $200,000

Labor savings: $90,000/year

Waste savings: $20,000/year

Increased premium output: $50,000/year

Annual benefit = $160,000

ROI = 80% per year → payback in ~15 months.

This reflects similar ROI principles found in vape machine ROI breaking even faster than expected.

What's a realistic ROI timeline?

For most mid-sized operators: 12–18 months, sometimes under a year, with high throughput.

Case Study 1: AI-Vision Boost in a Mid-Sized Facility

Before: 4 manual graders, 200 lbs/day, 10% rejects.

After: AI-vision + sensors, one operator, 500 lbs/day, 3% rejects.

ROI achieved in 10 months, labor cost reduced by 65%.

Case Study 2: Multi-Site Cannabis Brand

A multi-state operator deployed Sorting Robotics AI-vision systems across 3 facilities.

Results:

Consistent grading standards across all sites.

95% reduction in compliance defects.

Annual savings: $450,000 in labor + $120,000 in recovered premium product.

Future Trends in AI-Vision & Sensor Cannabis Sorting

Emerging trends likely to impact consulting:

Edge AI processing: faster, on-device decision making without cloud latency.

Self-learning models: continuous improvement based on new strain data.

Integrated compliance reporting: automatic generation of QC audit trails for regulators.

Automated SKU routing: sorting directly into strain-specific packaging lines.

These advancements mirror insights in closed vs open loop cartridge filling where feedback systems drive future scalability.

How Sorting Robotics Delivers Expert AI-Vision Consulting

Sorting Robotics specializes in cannabis-specific automation, offering:

On-site operational analysis.

Tailored hardware/software recommendations.

Full integration with conveyors, lighting, and compliance software.

Post-deployment performance tracking and retraining.

Unlike generic vendors, Sorting Robotics focuses exclusively on cannabis, just as starting a vape brand with the right filler shows the value of cannabis-first equipment design.

What makes Sorting Robotics consulting unique?

Its cannabis-first design approach ensures calibration accuracy for trichome-rich products, variable strains, and strict packaging laws.

Optimize Cannabis Sorting with AI-Vision Consulting Through SortingRobotics

In cannabis, precision and consistency directly affect profitability and brand strength. AI-vision and sensor systems can deliver those qualities at industrial speed but only if selected, configured, and maintained correctly. Consulting ensures that technology fits your process, maximizes ROI, and scales with your growth.

Ready to improve sorting accuracy and efficiency? Contact Sorting Robotics today to schedule a Robotics Consulting Services and transform your cannabis processing workflow.

Frequently Asked Questions

What's the main advantage of AI-vision in cannabis sorting?

AI-vision delivers consistent, high-speed quality control, reducing labor costs and protecting brand reputation.

How do sensor systems complement AI-vision?

Sensors add internal quality metrics like moisture and density to visual inspections, increasing decision accuracy.

Can small cannabis businesses benefit from AI-vision consulting?

Yes, scaled solutions can still cut costs and improve compliance for smaller operators.

How often should AI-vision systems be recalibrated?

Most require quarterly calibration to maintain 95%+ detection accuracy.

Does AI-vision comply with cannabis regulations?

Yes, when properly configured, it improves compliance by detecting non-conforming products before packaging.