How Batch Traceability Is Built Into Automated Cannabis Production Lines

Batch traceability in automated cannabis manufacturing is the ability to prove, using time-stamped records, which inputs, settings, operators, and packaging runs created each sellable batch. In regulated markets, the foundation is a compliant identifier and consistent tagging. California's CCTT–METRC guidance states that the licensee is responsible for assigning a unique identifier to each immature lot, flowering plant, harvest batch, production batch, and distinct cannabis product.

Automation can improve traceability by capturing key events as work occurs during receiving, processing, and packaging, reducing reliance on memory, handwritten notes, and spreadsheet reconciliation.

This guide breaks down the minimum data a traceable batch requires, where automated lines should capture it, and how to structure records that remain defensible during audits, investigations, and recalls.

Batch Traceability in Automated Cannabis Lines

Batch traceability becomes credible when “what happened” is captured as production happens, not reconstructed later.

What Batch Traceability Means on The Floor

A traceable batch is one you can follow forward into finished units shipped, and backward into every input lot and process step that touched it. In practice, your records should be able to answer: which source lots were used, which recipe version and setpoints ran, which line and shift executed the run, and which packaging outputs left the facility.

Why Automation Changes Traceability Quality

Manual workflows often depend on people remembering to scan, write down changes, and keep labels aligned during busy hours. Automated lines can reduce that exposure by logging timestamps, machine states, and recipe parameters directly from equipment events. Integrating a vape cartridge filling machine into your workflow allows for precise data logging that maps well to the GS1 'Identify, Capture, Share’ approach, where consistent identifiers and automated data capture can help keep traceability data complete and usable across systems.

What is batch traceability in cannabis manufacturing?

Batch traceability is the ability to track a production batch forward into shipped packages and backward into inputs, process steps, and documented events, using records that hold up during compliance review.

The Identifiers That Anchor Traceability

Cannabis batch identifiers showing Metrc UIDs and internal batch IDs across automated production

Traceability systems stay stable when identifiers remain consistent from raw inputs to shipped packages, even as the product is split, merged, staged, reworked, and repackaged.

Unique Identifiers from State Track-and-Trace

In most regulated programs, the state-facing identifier is the compliance anchor. In an automated facility, the operational objective is straightforward: every reportable object must be taggable at the moment it is created, received, combined, or packaged. Traceability often breaks when “temporary” unlabeled containers or “we’ll fix it later” batch creation becomes normal operating behavior.

Internal Batch IDs That Survive Through Processing

State identifiers keep you compliant. Internal IDs keep you operational. Internal batch IDs maintain continuity through intermediate states that the state system may not represent cleanly, such as work-in-process totes, split lots, merge events, staging buffers, rework loops, and partial pulls. A disciplined internal scheme also makes performance measurable at the batch level, including yield, downtime, defects, and changeover loss.

Labeling at The Right Granularity

Traceability breaks when the granularity is wrong.

Too broad can make risk hard to isolate, leading to over-holds or over-recalls.

Too narrow a label can create label overload, increasing the chance that the workflow gets skipped under pressure.

A practical balance is batch or lot-level IDs for materials and processing, and package-level IDs for finished goods, with tighter granularity used only where risk, process structure, or rules require it.

Do I need both internal batch ids and Metrc UIDs

In many facilities, yes. Internal batch IDs support operations, scheduling, and analytics, while state identifiers support required reporting and external traceability expectations.

Data Capture Points Across an Automated Line

materials move, transform, or become sellable.

Receiving and Material Staging

Traceability begins at receiving, not at production. Each inbound lot should record:

Item and supplier lot

Quantity received

Quarantine or release status

Storage location

Automation helps most when the workflow requires capture, such as:

Scan-then-weigh stations

Label printing

These steps cannot occur until the inbound lot is validated.

Transformation Events Inside Production Cells

Infusion, coating, filling, and packing are the highest-risk points because materials combine while units multiply quickly. For complex SKUs, an automated kief coating machine ensures that every unit is tracked during the application process. Strong capture should include:

Run identity and recipe version

Key settings used

Start/stop timestamps

Output counts and reject counts

Holds or exceptions

Operational discipline requires every split, merge, and rework loop to remain linked to the parent batch, keeping genealogy intact.

Packaging, Case Packing, and Shipping

Packaging is where a batch becomes revenue, and errors here are costly. Each production batch should track:

The packaging run that consumed it

Label version applied

Count produced, and any rejects

Transfer or shipment details

Semi-automated lines can enforce scan-to-pack logic, ensuring packages cannot be created without a valid batch reference.

Minimum Events to Log per Batch

At a minimum, capture:

Receiving

Batch creation and transformation events

Quality release or hold decisions

Packaging creation

Final shipment or transfer

Each event should be tied to identifiers, timestamps, and quantities.

Building a Clean Batch Record That Holds Up

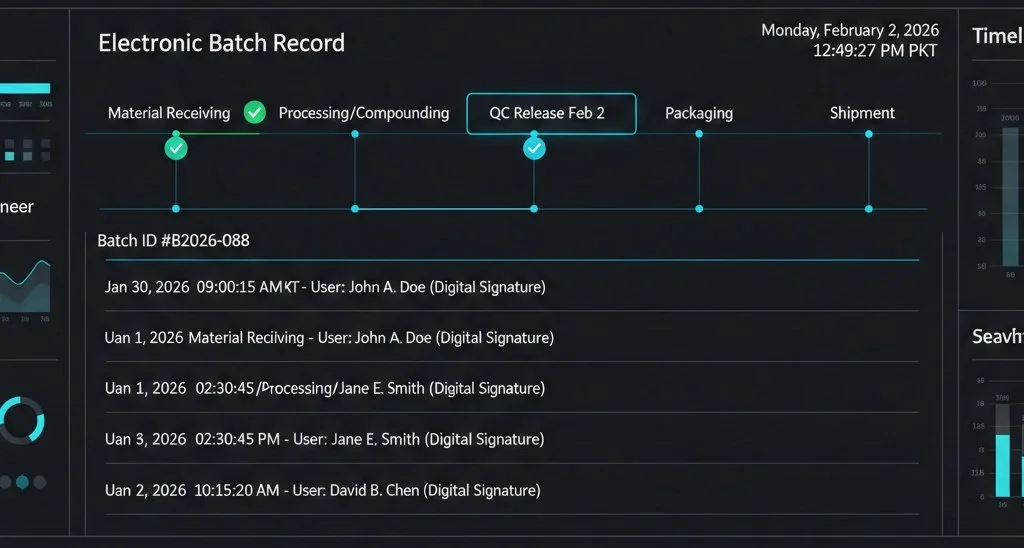

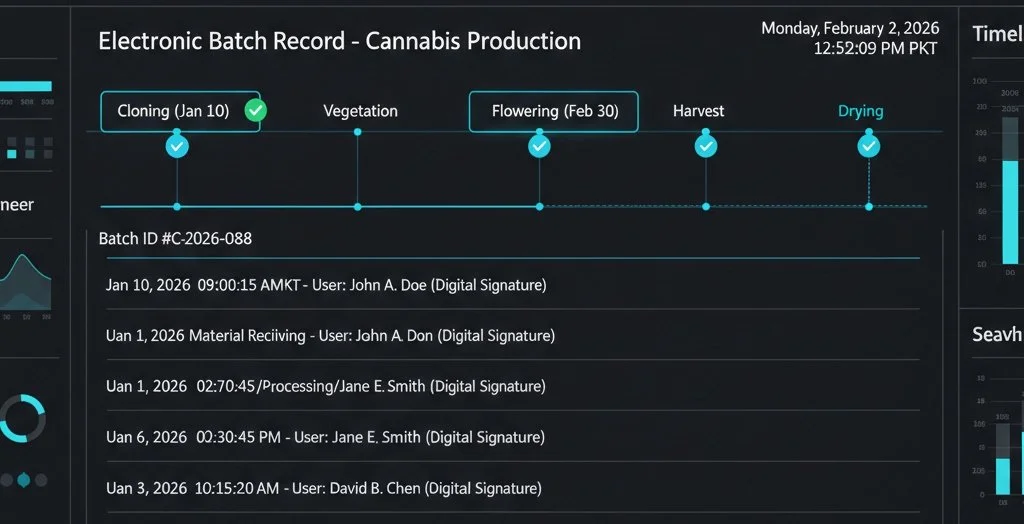

Electronic batch record timeline showing cannabis production events for audit and recall readiness

A strong system produces an electronic batch record that reads like a timestamped timeline, not a reconstructed story.

Recipe Control and Parameter Logging

Traceability tracks not only which lot but also under which conditions it was produced. For infused and coated products, capture:

Target dose and tolerance bands

Temperature windows

Timing and material-handling constraints

Both setpoints and actuals, when possible

This demonstrates that processes stayed within defined operating ranges, rather than relying on operator memory.

In-Process Checks and Exception Handling

A complete batch record includes what went wrong, not only what went right:

Holds, rejects, deviations, and rework

Structured events tied to the batch ID

Reason codes, disposition, and approvals

Automation helps by logging exceptions in real-time, reducing the need for after-the-fact gap-filling.

Linking Lab COAs to Production Batches

COAs are most defensible when attached to the exact production batch and flow forward into packaging lots.

Ensures one source of truth

Maintains batch genealogy, packaging linkage, and distribution footprint

Supports audits and recalls

Minimum Components of an Electronic Batch Record

Identifiers and material genealogy

Timestamps for each event

Recipe versions and key process parameters

Quality decisions

Packaging links and shipment references

Organize all of this as an event timeline, not a reconstructed narrative.

Making Traceability Hold Up in Audits and Recalls

Traceability only “counts” when you can produce the same answer every time, using system evidence, under time pressure. Audits and recalls test three things at once: completeness (nothing missing), linkage (everything connected), and speed (no reconstruction).

One-Step-Back and One-Step-Forward is The Baseline

At a minimum, you should be able to trace backward into direct inputs and forward into direct outputs and transfers without improvisation. In cannabis terms, that means clean material genealogy plus a clear record of where the product moved next.

Mock Recalls and Time-To-Answer

Mock recalls are the most practical stress test. Choose a batch, then produce three outputs without manual rebuilding:

Which finished packages were consumed in that batch

where those packages were transferred or shipped

Which adjacent batches could be implicated due to shared runs, rework, or packaging overlap

Automation helps when packaging and shipping events are captured during the process rather than reconciled after the shift. A robotic cannabis packaging systems ensures that every unit is accounted for in real-time.

Common Failure Modes in Automated Facilities

Many failures come from seams between systems rather than equipment performance. Common gaps include undisciplined receiving, unlabeled work-in-process containers, rework handled outside the system, and packaging runs created without hard links back to production batches. The usual fix is workflow enforcement: required scans to proceed, controlled label printing, and batch-close steps that cannot be skipped.

How fast should I be able to trace a batch during an audit

Fast enough to produce a complete backward-and-forward genealogy during the audit window without rebuilding the story from memory or spreadsheets.

A Practical Implementation Plan for Automated Traceability

Traceability implementations perform best when they begin with a tight scope, enforce the workflow end-to-end, and expand only once the records are consistently clean. The objective is not “more data.” It has fewer gaps, fewer exceptions, and faster answers.

Start With Two High-Volume Skus

Select SKUs that reflect real operating conditions: frequent enough to generate meaningful data, stable enough to standardize, and valuable enough that errors matter. Use them to lock batch definitions, event points, and label rules before expanding to the full catalog. For those producing specialty items, standardizing the make kief coated pre-rolls process is an excellent place to start as it involves multiple material inputs.

Map Events, Owners, and Systems

Traceability breaks when it is "everyone’s job." Assign clear ownership to each event point: receiving, batch creation, transformation, QC release, packaging, and shipping. Each owner should have a single, repeatable system action at that point, such as scan, weigh, approve, print, or close. The objective is a workflow where compliance is the default path, not an extra task.

Validate, Train, and Lock Sops

Even automated traceability depends on operator behavior at handoffs. Training should focus on the actions that create permanent records: starting a batch, changing a recipe, placing a lot on hold, executing rework, and closing a packaging run. Once those are stable, batch records become consistent and defensible.

How do I implement batch traceability without slowing the line

Start with a small SKU set, enforce scans only at the highest-risk handoffs, and automate machine parameter capture so operators are not required to manually "write the record."

Unlock Audit-Ready Production With Automation

Batch traceability is not only a compliance task; it can also serve as a production control system that reduces investigation time, isolates risk more quickly, and makes quality and throughput more measurable. When automated lines capture events and parameters as work is being done, the batch record becomes an operational asset for audits, customer confidence, and continuous improvement, not a report you rebuild under pressure.

You now have a practical operating model to define batch objects, choose identifiers, capture events at the right handoffs, and convert machine data into an electronic batch record that holds up when it matters.

Contact Sorting Robotics to map your traceability workflow, implement scan-to-pack automation, and build audit-ready batch records using our Jiko pre-roll infusion systems, Stardust kief coating machines, and custom automation solutions. Turn compliance into a competitive advantage while improving operational efficiency.

Frequently Asked Questions

How long should batch traceability records be retained?

Retention is typically driven by state rules, product type, and business risk; set a documented retention policy that meets the strictest jurisdiction you operate in.

Should traceability systems be cloud-based or on-premise?

Cloud is common for multi-site visibility and easier updates, while on-prem can appeal where connectivity and local control are priorities; many facilities use hybrid designs.

How do you handle rework without breaking batch genealogy?

Treat rework as a formal transformation event with its own identifier, linked back to the parent batch and forward to the new output batch.

What is the biggest operational risk to traceability in automated plants?

Work-in-process handling that happens outside the system, unlabeled containers, unscanned transfers, and informal rework loops.

How do multi-state operators keep traceability consistent across different rules?

Use a single internal batch model and event map across all sites, then translate the required reporting fields per state on top of that internal standard.