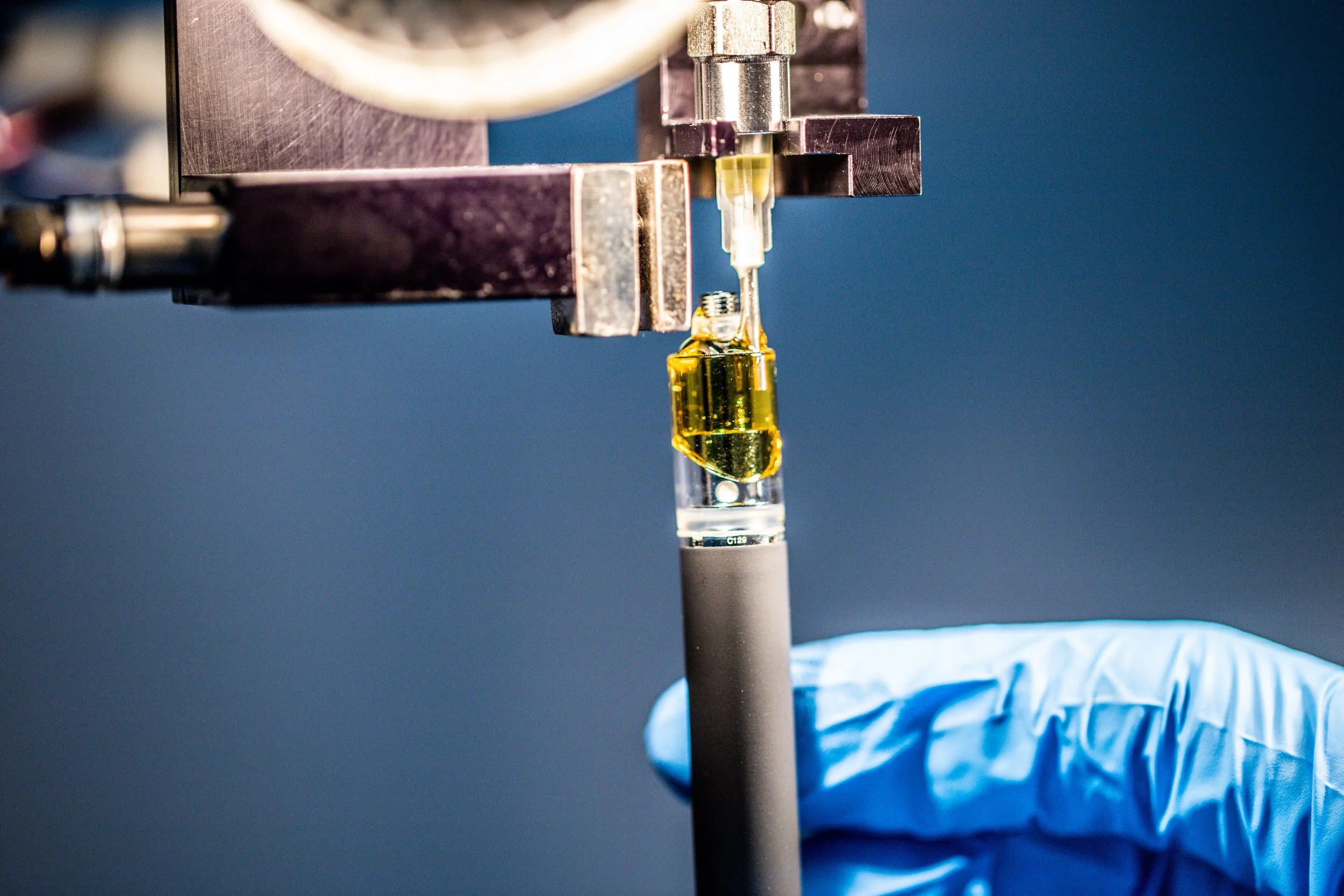

How Oil Thickness Changes Your Cartridge Fill Rate

Filling vape cartridges may seem straightforward, but anyone who has worked with different oils knows it can quickly become tricky. One of the primary factors that affects how quickly and accurately cartridges are filled is the thickness of the oil, also known as viscosity.

Thicker oils flow slowly, which can slow down production and create inconsistencies. Thinner oils move quickly but can lead to leaks or overfills if not handled carefully.

A technical study on e-liquid viscosity shows that liquids with higher VG content are noticeably thicker, while heat makes them thinner. It also found that flavor additives can alter the flow of the liquid. The study warns that liquids that are too thin are more likely to leak from cartridges, which brings up the importance of understanding viscosity to maintain a consistent and efficient filling process.

This blog explains how oil thickness affects cartridge fill rates, the factors that influence viscosity, and provides practical tips to improve efficiency. Read on to understand how to balance speed, precision, and quality to ensure a smooth and reliable cartridge filling process.

What is Oil Viscosity and Its Role in Cartridge Filling

Oil viscosity is simply how thick or thin an oil is. You can think of it like honey versus water, as honey is thick and moves slowly, while water is thin and flows quickly. In vape cartridges, oil viscosity is important because it affects how fast the oil can be filled into each cartridge and whether the filling process is clean and precise.

Definition of Viscosity and How It’s Measured

Viscosity measures how resistant a liquid is to flow. The thicker the oil, the higher the viscosity. In labs or production facilities, viscosity can be measured using special tools like a viscometer, which shows how easily the oil moves at a certain temperature. Knowing the viscosity helps operators adjust the filling speed and equipment settings to achieve the best results. This is why how viscosity affects vape cartridge filling is such a critical factor in production.

Types of Vape Oils: Distillates, Live Resin, Rosin

Not all vape oils have the same thickness, and typically, there are three types of vape oils:

Distillates: Technical insights from Cannabis Science & Technology show that distillates are thick, highly refined cannabis extracts with very high THC content and few other compounds. They’re viscous at room temperature, and often require heat or added terpenes impact vape cartridge performance to flow properly.

Live Resin: Made from freshly frozen cannabis plants to preserve terpenes and cannabinoids. This oil is more aromatic and flavorful and tends to be less viscous than distillate, making it easier to handle.

Rosin: A solventless extract created using heat and pressure. It’s often thick and sticky, offering a full-spectrum profile, but requires more care during filling due to its dense consistency.

Each type of oil requires different handling, so understanding the oil you are working with is crucial for a smooth cartridge filling process.

How Extraction Methods Affect Oil Consistency

The way an oil is made also affects its viscosity. Solvent-based extractions often produce oils that are thinner, whereas solventless methods, such as pressing or rosin, can yield thicker oils. Even the way an oil is stored, like keeping it cold or warm, can change how thick it feels. This is why operators must consider extraction methods and storage when preparing for filling.

How Oil Thickness Impacts Cartridge Fill Speed and Efficiency

Oil thickness plays a major role in how quickly cartridges can be filled. Thicker oils move slowly, while thinner oils flow more quickly, but both present unique challenges that impact production and quality.

Let’s break it down.

Thicker oils and slower fill rates

A study published in the National Institutes of Health's PubMed Central shows that thicker, high-viscosity oils can slow down filling machines, affect how smoothly the oil flows, and make it harder to fill cartridges accurately.

Thicker oils, like some distillates or live resins, have a slower flow through filling machines. This means each cartridge takes longer to fill, which can reduce overall production speed. The slow flow also increases the likelihood of air bubbles forming, which can result in uneven cartridge weights.

To manage thick oils, many manufacturers heat the oil slightly before filling. This reduces the viscosity, allowing it to flow more smoothly without compromising quality. Using the correct nozzle size and machine pressure also helps maintain a consistent fill rate. With proper preparation, even thick oils can be filled efficiently.

Thinner oils and risk of leaks

Thin oils flow quickly, which can speed up production significantly. However, the faster flow can create problems, such as overfilling or leaks, if the machine or cartridge is not suited for low-viscosity oils.

Thin oils also increase the chance of spillage during transfer, which can waste material and create cleanup issues. Manufacturers often adjust machine speed, nozzle diameter, and fill volume to prevent leaks. By controlling these factors, thin oils can be filled quickly while still keeping cartridges neat and properly sealed.

Balancing flow rate for precise fills

Finding the right balance between speed and accuracy is key. Neither too thick nor too thin is ideal without proper adjustments. Many producers monitor viscosity, temperature, and machine settings together to achieve precise fills consistently.

The goal is to maintain a smooth flow that matches the cartridge size and prevents air pockets or leaks. Testing small batches first can help determine the best combination of heat, pressure, and nozzle size for each oil type. This balance ensures efficient production while maintaining high-quality cartridges.

Factors That Influence Oil Viscosity in Cartridge Filling

Several factors can affect the thickness or viscosity of your vape oil, which directly impacts cartridge fill rates. The main influences include temperature, terpene content, additives, and storage conditions.

Let’s explore each in detail.

Temperature: heating oils for optimal flow

Temperature is one of the most important factors affecting oil viscosity. Warmer oils become thinner and flow more easily, which can speed up cartridge filling and reduce clogs. On the other hand, cold oils are thick, sticky, and slow to move through filling machines.

Most vape oils perform best when gently heated to 100–130°F.

Heating should be gradual to avoid damaging terpenes or cannabinoids.

Precision heating equipment helps maintain a consistent flow, preventing inconsistencies between cartridges.

Terpene content and natural thinning effects

Terpenes are naturally occurring compounds that give oils their aroma and flavor. They also thin out thick oils, making them easier to fill.

Oils with higher terpene levels are generally less viscous.

Low-terpene oils may require pre-heating or thinning to flow properly.

Knowing the terpene profile can help predict how the oil will behave during filling.

Additives and cutting agents for flow adjustment

Some manufacturers use additives or cutting agents to modify the thickness of the oil. These substances can make thick oils flow more easily and enhance production efficiency.

Common cutting agents include MCT oil or PG/VG blends.

Additives should be used carefully to avoid affecting taste or cartridge performance.

Proper dosing ensures consistent viscosity without compromising quality.

Storage and environmental effects on viscosity

The way oils are stored can also change their viscosity. Temperature fluctuations or exposure to light can cause oils to become thicker or thinner than expected.

Oils stored in cold conditions may solidify or slow down during filling.

High temperatures can thin oils too much, which can eventually lead to leaks.

Keeping oils in controlled environments helps maintain consistent flow.

Relevant fact: One way to control oil viscosity is through the use of terpenes. According to a 2023 study by the University of California, Davis, adding terpenes to cannabis oils can lower their viscosity. Thinner oils flow more easily and help achieve the right consistency for efficient cartridge filling and reducing the risk of clogs or uneven fills.

How To Maintain Proper Oil Thickness for High-Quality Vape Cartridges

Maintaining the right oil thickness is crucial for producing vape cartridges that fill consistently and perform well. If the oil is too thick, it can slow down production and clog filling machines. On the other hand, oil that is too thin can leak, overfill, or even affect the taste and user experience.

By carefully managing viscosity, manufacturers can enhance efficiency and product consistency while preserving the integrity of the oil.

Preventing Clogs and Machine Downtime

Clogs happen most often when thick oils are not properly prepared for filling.

To avoid this, you should:

Preheat thick oils slightly to make them flow easier without degrading terpenes or cannabinoids.

Use clean and well-maintained filling equipment. Residue buildup can worsen viscosity issues.

Check the nozzle size to match the oil’s thickness. Smaller nozzles may slow the filling process, while larger nozzles allow for smoother flow.

Achieving Consistent Cartridge Weight and Volume

One of the biggest challenges with varying oil thickness is maintaining uniform cartridge weight and volume. Uneven fills can frustrate consumers and harm your brand reputation.

To manage this:

Measure batches carefully before filling. Consistent amounts of oil in each reservoir help standardize output.

Calibrate your filling machines regularly to match oil viscosity. Even small adjustments can make a noticeable difference.

Monitor fill speed. Slower fills for thick oils often produce more accurate volumes, whereas faster fills are more suitable for thinner oils.

Avoiding Leaks, Waste, and Equipment Damage

Leaks are a common problem when oil is too thin or improperly heated. Similarly, overly thick oil can strain filling machines and cause damage. To prevent these issues:

Adjust the temperature carefully. Warm oils flow smoothly, but excessive heat can damage the cartridge or oil quality.

Check cartridge seals and gaskets before filling. Properly sealed cartridges prevent leaks even when oils are thin.

Use oil-specific filling equipment. Some machines are better suited for thicker oils, while others work best with thinner varieties.

When following these steps, you can expect fewer rejects and a longer lifespan for your filling equipment.

Supporting Shelf Life and User Experience

Oil thickness also impacts the final product after filling. If oil is too thin, it may settle or leak in storage. If too thick, it can affect vapor production.

To maintain a positive user experience:

Store cartridges at the right temperature to maintain stable oil consistency over time.

Blend oils carefully if using additives or terpenes. Uniform consistency prevents separation.

Test batches regularly to make sure viscosity stays within the ideal range for filling and use.

How You Can Use Temperature Control to Optimize Fill Rates

Temperature control can make filling vape cartridges much easier and faster. Thick oils move slowly, which can cause delays and uneven fills, while oils that flow too quickly may leak or overflow. Warming the oil to the right level helps it move smoothly, letting machines fill cartridges efficiently and consistently.

Adjusting the temperature also preserves the oil’s flavor, color, and potency. Small changes in temperature can have a significant impact on flow, so monitoring the temperature during filling helps reduce waste and prevent common mistakes. With the right heating approach, you can make sure your production stays fast without compromising quality.

Ideal Temperature Ranges for Various Oil Types

Different oils need different temperatures to flow correctly. Distillates typically perform best at temperatures between 120 and 150 degrees Fahrenheit, while live resin and rosin, which are thicker and richer in terpenes, may require temperatures of 140 to 170 degrees.

Heating oils too little can make them sluggish, slowing production, while overheating can cause leaks and affect flavor. Checking the temperature for each batch keeps the oil at the right thickness so every cartridge receives a consistent fill.

Benefits of Precision Heating Systems

Precision heating systems give you control over small temperature changes. They prevent overheating, which can damage terpenes, and reduce clogs in nozzles. Machines fill cartridges more accurately and waste less material. These systems also help maintain steady production, which is especially important for large batches.

Maintaining Speed, Consistency, and Product Integrity

Heating the oil evenly helps cartridges fill at the same pace. This balance keeps production fast and reliable, while protecting the oil’s flavor and potency. When temperature is controlled, batches stay uniform, machines run smoothly, and customers get a high-quality product every time.

How to Choose the Right Cartridge Filling Equipment for Different Oils

How to Choose the Right Cartridge Filling Equipment for Different Oils

Picking the right machine depends on oil type and viscosity. Thick oils like rosin require heated reservoirs and stronger pumps, while thinner oils like distillates need precision to avoid overfilling. For operators, how to choose the right vape cartridge filling machine ensures the best match for their production scale.

Here are some key points to guide you when choosing cartridge-filling equipment:

Machines for thick vs. thin oils: Thick oils, such as live resin or rosin, require equipment with stronger pumps or syringes that can push the oil without clogging. Thinner oils, such as distillates, flow easily but require precision to avoid overfilling or leaks.

Heated reservoirs and nozzles: Equipment with adjustable heating helps maintain proper oil viscosity during filling. You can control flow without overheating, which keeps the oil’s flavor and potency intact.

Automation level and batch size: For smaller batches, manual or semi-automatic machines may be enough. Larger production runs benefit from fully automatic systems that maintain consistent fills while reducing operator fatigue.

Ease of cleaning and maintenance: Machines that are easy to clean prevent buildup and contamination, especially when switching between different oils. This keeps production efficient and reduces downtime.

Precision controls: Look for equipment with adjustable settings for fill volume, speed, and temperature. This lets you fine-tune every batch for consistent, high-quality results.

Common Mistakes When Filling Cartridges With Different Oil Thicknesses

Filling vape cartridges can be tricky, especially when different oils behave differently. Small mistakes can slow down production, waste oil, and lower the quality of your cartridges.

Paying attention to these common pitfalls helps you keep the process smooth and consistent:

Overheating Oils and Degrading Terpenes

Heating oil can make it flow more easily, but too much heat can ruin the terpenes that give the oil its flavor and aroma. When terpenes break down, the oil can lose its taste, smell, and quality. Slowly adjusting the temperature and checking the oil often helps it stay smooth without losing its natural properties.

Using Incompatible Cartridges or Equipment

Not all cartridges or machines work well with every type of oil. Thick oils need stronger pumps, while thin oils require precision to avoid leaks. Using the wrong cartridge or equipment can cause spills, clogs, or wasted oil. Matching your oil type to the right tools keeps your fills clean and consistent.

Skipping Oil Prep or Pre-Heating

Some oils need a slight warming or stirring before filling. Skipping this step can make it difficult to push thick oils through the machine or cause uneven fills. Prepping your oil first helps it flow smoothly, fills cartridges evenly, and protects your equipment from stress.

Not Calibrating Machines for Specific Viscosities

Every oil has its own thickness, and machines need proper settings for accurate filling. Machines that are not calibrated can overfill, underfill, or leak. Regularly checking and adjusting settings ensures batches are uniform, reduces waste, and guarantees that every cartridge meets quality standards.

Tips to Improve Cartridge Fill Rate Without Compromising Quality

Improving your cartridge fill rate does not have to come at the cost of quality. Small changes in how you handle oil, equipment, and workflow can make a big difference. Here are practical tips to help you fill faster and smarter:

Pre-heat oils before filling: Gently warm thicker oils to make them flow more easily. This reduces resistance in the machine and keeps the fill even.

Mix oils for uniform consistency: Stir or gently blend oils if they have separated or settled. This ensures every cartridge receives the correct volume and prevents clogs.

Adjust machine settings for each batch: Fine-tune fill volume, speed, and pressure depending on the oil’s thickness. Small adjustments prevent leaks, overfills, and wasted product.

Use the right cartridge type: Match your oil viscosity with cartridges designed to handle it. Proper fit reduces spills and makes filling smoother.

Organize workflow for efficiency: Keep oil, cartridges, and equipment ready before starting a batch. A clean, organized workspace minimizes interruptions and keeps production moving.

Regularly maintain and clean machines: Remove buildup in nozzles, pumps, and reservoirs to prevent clogs. Clean equipment keeps oil flowing smoothly and maintains consistency.

Monitor batches closely: Watch fills during production. Spotting small issues early, like temperature drops or uneven flow, prevents mistakes from affecting the whole batch.

Use temperature monitoring tools: Thermometers, infrared sensors, or temperature-controlled filling stations help keep oil at the perfect viscosity.

Track batches and document settings: Record oil type, temperature, and machine adjustments. This creates a reference for future batches, improving efficiency and consistency.

Train operators on handling oils: Staff who know how to adjust machines and handle different viscosities work faster and make fewer mistakes.

Store and handle oils properly: Keep oils at the recommended temperature, away from light, and gently mix them before filling to maintain ideal flow.

Troubleshoot flow problems quickly: Learn to fix clogs, air bubbles, or uneven fills as they happen to avoid wasting oil or slowing production.

Follow safety and hygiene practices: Hot oils can be hazardous, and maintaining clean workspaces prevents contamination, which in turn keeps both fill rates and product quality high.

Boost Your Cartridge Fill Rate With Precise Oil Thickness Control

Filling vape cartridges quickly does not have to come at the cost of quality. Paying attention to oil thickness, controlling temperature, choosing the right equipment, and avoiding common mistakes keeps every batch smooth, consistent, and reliable. With the right preparation and machine settings, you can make sure every cartridge is filled accurately while preserving flavor, potency, and appearance.

At Sorting Robotics, we understand the challenges of working with oils of different viscosities. That is why we designed the Omni-Filler for high-precision cartridge filling and our pre-roll infusion machines for consistent, efficient production, so you can save time, reduce waste, and maintain consistent quality in every batch. Our solutions are built to help you achieve high-precision filling without the frustration of slow production or inconsistent results.

When you partner with Sorting Robotics, you get faster, smoother, and more reliable cartridge production that meets the high standards your customers expect. Take control of your cartridge production today with our automation systems. Get in touch with us today!

Frequently Asked Questions

What to do if cart oil is too thick?

If your cartridge oil is too thick, it may flow slowly or not vaporize properly. For manufacturers, warming the oil slightly can help reduce viscosity and improve filling. For consumers, gently warming the cartridge in your hands or placing it in a warm water bath (not hot) can make vaping easier. Avoid shaking aggressively or heating with open flames, as that can damage the cartridge or oil.

Why is my vape cart not full?

A cartridge may appear underfilled due to production variation, air bubbles, or settling of the oil over time. Some cartridges are intentionally not completely full to prevent leaks and allow expansion during heating. If a cartridge consistently appears underfilled and performance is affected, it may indicate a manufacturing issue.

How long are oil cartridges good for?

Most vape cartridges last 6 to 12 months if stored properly. Store them in a cool, dark place, away from direct sunlight and heat. Avoid leaving them in a hot car or near heat sources. Over time, oil may darken or thicken, and the flavor or potency may decrease.

What is cart oil supposed to look like?

High-quality cartridge oil is usually clear to amber in color. It should be free from debris or cloudiness. Thick oils may look darker and more viscous, while thinner oils may be more transparent. Changes in color over time are normal, but unusual cloudiness, sediment, or separation could indicate poor storage or contamination.

Is it bad to smoke a brown cart?

A brown cartridge does not automatically mean it is unsafe. Over time, oils can darken due to exposure to light, heat, or oxygen. This can slightly change flavor or potency, but many oils remain safe to vape if stored properly. However, if the oil is very dark, has a burnt smell, or shows unusual sediment, it may be degraded or contaminated, and it is safer not to use it.

Why is my cart not hitting but has airflow?

If your cartridge has airflow but does not produce vapor, common causes include thick oil, a clogged coil, or a weak battery connection. Thick or old oil may not vaporize well. Check that the battery is fully charged and connected correctly. Warming the cartridge gently can thin the oil and improve vapor production. Avoid forcing the cart or overheating, as that can damage the coil or battery.