How to Pick the Right Tray Size for Your Vape Carts

Selecting the right tray size for filling vape cartridges is more than a technical choice. It is a decision that shapes efficiency, consistency, and cost control in cannabis production facilities. A poorly matched tray can cause misaligned cartridges, uneven fills, or unexpected downtime that disrupts output.

The U.S. vape cartridge market continues to grow as one of the most dominant cannabis product categories. According to the National Institute for Cannabis Investors, vape cartridges were the second-largest product category in cannabis retail, capturing over 24% of total sales across major U.S. markets by Q1 2024. This scale of demand underscores the importance of tray precision and compatibility in meeting production targets without compromising quality.

This guide explains how to select trays that optimize filling performance. Topics include cartridge compatibility, tray materials, alignment accuracy, and long-term maintenance.If you’re scaling operations, tray precision is just as critical as investing in the right vape cartridge filling machine

How Do You Determine the Right Tray Size for Your Cartridges?

Choosing the proper tray size requires understanding the dimensions and behavior of your specific cartridge types. Here's what you need to know before selecting a tray.

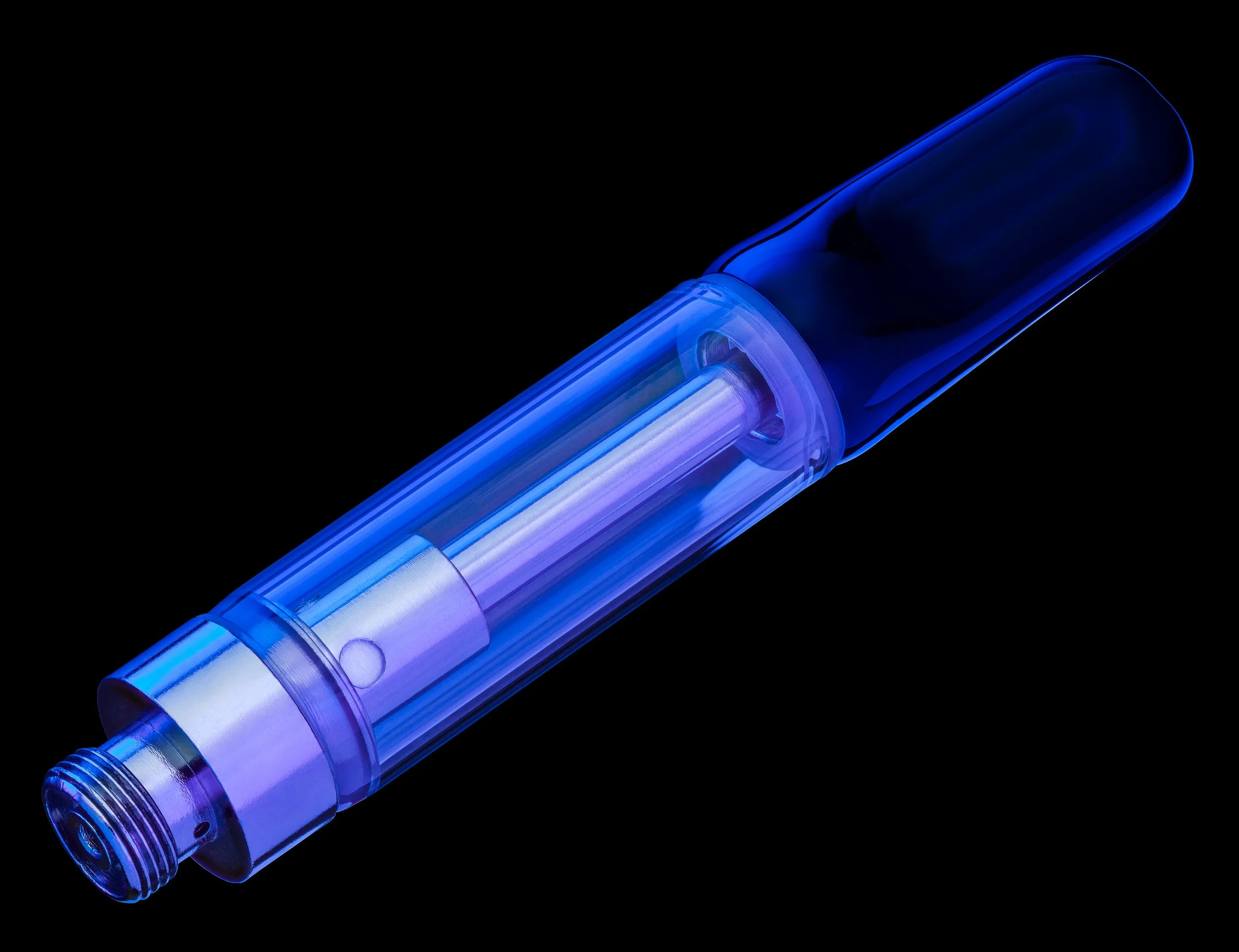

Cartridge Size Compatibility

Different cartridge volumes demand different tray sizes:

0.3mL (third gram): Best suited for compact trays (for example, 5 inches by 7 inches) during testing or R&D batches.

0.5mL (half gram): A standard across many facilities. Medium trays (7 inches by 11 inches) are commonly used.

1.0mL (full gram): Requires oversized trays (12 inches by 12 inches or more) to handle larger production runs.

Vape cartridges represent roughly 25% of total cannabis sales, making them one of the most significant product segments in the U.S. market. Meanwhile, the global market for vape cartridges continues to expand rapidly, valued at USD 1.81 billion in 2024 and expected to reach USD 6.0 billion by 2030. These trends underscore the need for precise and scalable tray solutions to handle high-volume, high-demand formats efficiently just like automated filling systems improve accuracy and reduce waste in vape oil filling in large-scale labs.

Aligning with Production Volume

Your daily production target directly affects the tray size and capacity you should use:

Low volume (fewer than 500 carts per day): Semi-automated systems work best with compact trays.

High volume (more than 1000 carts per day): Full automation pairs well with oversized, 100-slot trays.

Just like how to automate kief coated pre roll production, upgrading tray formats for vape carts is all about scaling without sacrificing quality.

Matching the Machine: System Compatibility

Automated systems: These typically require proprietary, high-precision trays. Each tray holds 100 cartridges and supports various cartridge sizes.

Semi-automated systems: These allow for flexible tray formats but may require manual alignment.

Manual systems: Generic trays are often used, though they may lack the consistency needed for larger-scale processes.

What Tray Design Features Help Improve Fill Accuracy?

Beyond size, the structure and materials of your trays play a massive role in workflow, cartridge stability, and maintenance. Let's examine the design and material options that matter most.

Design Features That Improve Efficiency

Curved Edges: Helps prevent cartridge tipping and oil spillage during movement.

Tool Compartments: Slots for syringes, caps, or torque tools streamline workflows.

Raised Walls (1 to 2 cm): Prevents carts from slipping or tipping, particularly useful for live resin.

Comparing Tray Materials

| Material | Pros | Cons |

|---|---|---|

| Metal (Aluminum, Stainless Steel) | Highly durable, easy to sanitize | Higher cost |

| Plastic (Polycarbonate) | Lightweight, affordable | Scratches easily, may warp over time |

| Silicone | Flexible, slip-resistant | Not suited for high-heat environments |

Industry resources highlight that stainless steel trays are highly effective at maintaining hygiene during cannabis processing. Stainless steel is easy to sanitize, helping prevent cross-contamination between batches or strains, and is favored in regulatory settings where sanitation is strict. For example, the Massachusetts cannabis control regulations require that products be handled on food-grade stainless steel surfaces, thereby minimizing contamination risks.

Cartridge Stability and Slot Precision

Engineering research indicates that even minor misalignments lead to degraded performance and increased operational errors. For example, journal bearings experience reduced fluid film thickness and increased wear under misaligned conditions. Applying this principle in vape cartridge filling underscores the value of precision-fit trays, particularly those with machine-vision validation or custom-cut slots for 510-thread cartridges, to mitigate filling errors.

How Can You Select and Maintain the Right Tray for Long-Term Use?

Even with a well-matched tray, incorrect implementation or poor maintenance can lead to inefficient filling cycles. Here's how to optimize tray usage on the floor.

Match Tray to Cartridge and Use Case

| Cartridge Size | Suggested Tray | System Type | Use Case |

|---|---|---|---|

| 0.3mL | 5 inches by 7 inches | Semi-automated | R&D or small batches |

| 0.5mL | 7 inches by 11 inches | Automated | Standard production |

| 1.0mL | 12 inches by 12 inches or more | Automated | High-volume runs |

Test with Dry Run Mode (if available)

Use tray alignment checks without oil to verify:

Fit and stability of cartridges

Alignment accuracy with nozzles

No need to waste distillate during testing

Maintenance and Storage

Cleaning: Use 91% or higher isopropyl alcohol to remove oil and residue

Storage: Keep trays dry and away from UV exposure to prevent material degradation

Regulatory standards emphasize the importance of cleaning processing equipment at regular intervals to prevent contamination and ensure operational precision. Applying this standard to vape cartridge trays supports optimal alignment and hygiene, which are essential for maintaining fill accuracy and minimizing production errors.

Organization Tips

Use color-coded or labeled trays for different cartridge types.

Assign each tray a software profile in automation platforms to reduce manual entry errors.

What Common Problems Do Brands Face With Tray Selection?

Choosing the wrong tray leads to a host of operational headaches. But most can be prevented with a few proactive decisions.

Mismatched Tray and Cartridge Sizes

Issue: Causes tipping, underfilling, or leaks.

Solution: Use adjustable, precision-fit trays and machine vision alignment.

Residue and Hygiene

Issue: Sticky residue causes misalignment and makes cleaning difficult.

Solution: Use stainless steel trays and a consistent cleaning routine.

Scaling Without Errors

Issue: Manual trays slow throughput and reduce consistency.

Solution: Oversized trays with automated alignment ensure uniform performance.

Just as brands struggle with tray mismatches, pre-roll producers often face similar issues with kief coating mistakes or oil infusion. The solution in both cases is automation and precision.

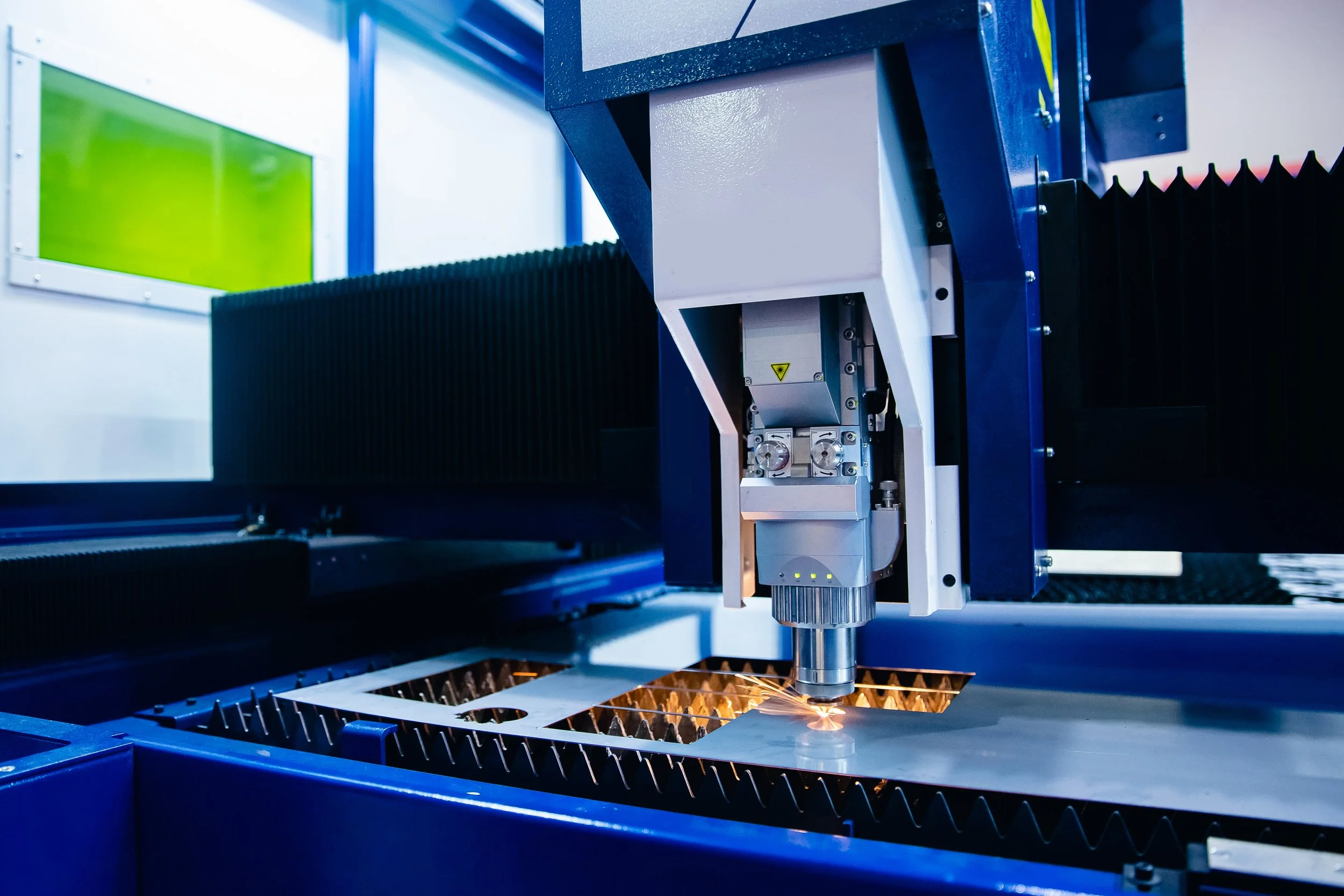

Why Do Automation and Precision Matter in Tray Design?

Advanced vape filling systems rely on high-quality trays to achieve speed and precision. Poor tray design leads to misalignment, spillage, and material waste.

Efficiency

Automation platforms equipped with high-capacity trays (capable of holding 100 cartridges) are capable of performing batch fills in under 75 seconds. For high-throughput labs, this can equate to thousands of extra carts filled per shift.

Safety

Using non-porous materials like stainless steel ensures that trays remain compliant with hygiene standards, reducing cross-contamination and microbial growth.

Technology

Modern platforms pair trays with software and sensor-driven alignment features. This reduces human error and optimizes every batch with machine-specific settings.

Optimizing Tray Size for Vape Cart Precision

From cartridge volume and production scale to tray material and machine alignment, every element of tray selection plays a critical role in vape cartridge filling efficiency. The right tray minimizes errors, improves hygiene, and supports both small-batch and high-volume operations through more intelligent automation and precision.

Ready to streamline your workflow and scale with confidence? Contact Sorting Robotics at +1 (747) 298-7429 or visit www.sortingrobotics.com to request a personalized demo and explore our optimized tray solutions.

Frequently Asked Questions

How do I determine the right tray size for my vape cartridges?

The tray size depends on the cartridge volume (0.3mL, 0.5mL, or 1.0mL) and your production volume. Compact trays are suitable for small batches and R&D, medium trays fit standard production, and oversized trays handle high-volume runs. Machine and system compatibility also influence the choice.

What tray materials are best for vape cartridge filling trays?

Stainless steel is highly durable and easy to sanitize, making it an ideal material for maintaining hygiene and ensuring regulatory compliance. Plastic trays are lightweight and affordable, but can scratch and warp. Silicone trays are flexible with slip resistance but are not suitable for high-heat environments.

Why is cartridge and slot alignment critical in tray selection?

Precise alignment prevents operational errors, such as misfilling, and reduces wear. Tray designs with custom-cut slots or machine-vision validation help ensure stable cartridge positioning and consistent fill quality.

How does tray size impact production efficiency?

Using the proper tray size, matched to the production volume and cartridge type, optimizes filling speed, reduces downtime, and enhances consistency. For example, high-volume production benefits from 100-slot, oversized trays that are compatible with automated systems.

How should I maintain and clean vape cartridge trays?

Regular cleaning with 91% or higher isopropyl alcohol removes residue and prevents contamination. Trays should be kept dry and stored away from UV exposure to avoid material degradation and maintain operational precision.

What common problems arise from poor tray selection?

Issues include cartridge tipping, leaks, underfilling, difficulty in cleaning due to residue buildup, and slowed throughput. Choosing adjustable, precision-fit trays and maintaining strict cleaning routines can mitigate these problems.