Scaling Your Cannabis Production with Jiko's Modular Automation

Cannabis brands pushing past their first production milestones often discover an uncomfortable truth: infused pre-rolls sell fast, but scaling them manually creates chaos. With the infused pre-roll category generating over $1.75 billion in sales in just the first half of 2024 alone, according to MJBizDaily and Headset data, the pressure to meet demand is immense.

When you are producing small batches, a team of dedicated technicians can maintain quality through sheer focus and artistry. However, as demand climbs, the math stops working. More workers mean more variability in the final product. More batches mean more inconsistency between shifts. Somewhere between hiring your fifth infusion technician and fielding your tenth customer complaint about uneven burns, the operational cracks begin to show.

The solution isn't simply working harder; it is about changing the infrastructure of your production.

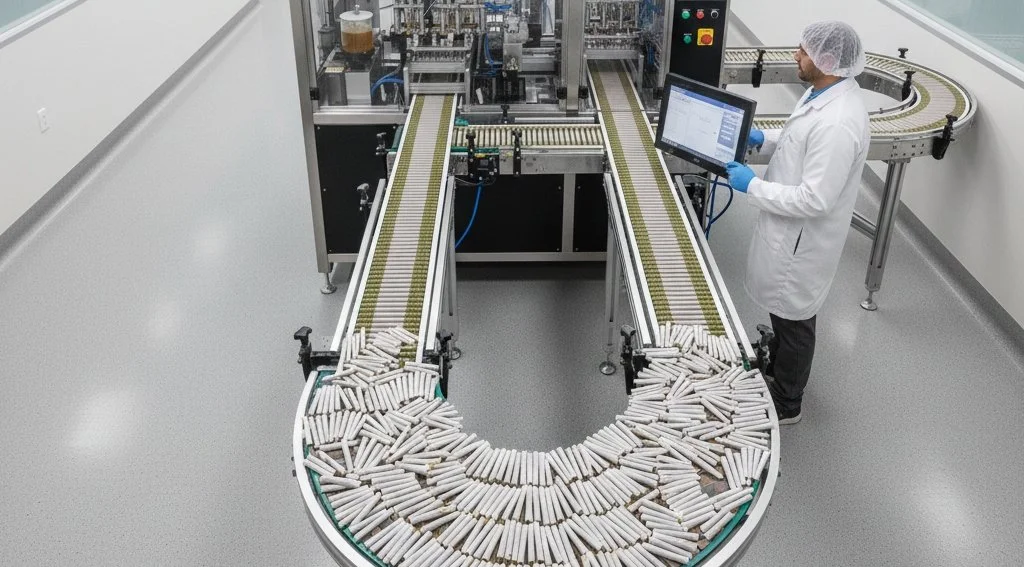

Scaling your cannabis production with Jiko's modular automation transforms how operations approach the infused market. Jiko removes the bottleneck that keeps most brands stuck between craft batches and commercial volume. By enabling throughput exceeding 1,000 units per hour with single-operator simplicity and interchangeable components that adapt to any joint or blunt size, Jiko offers the flexibility needed to grow without sacrificing the quality that built your brand.

Understanding why manual infusion fails at scale reveals exactly where Jiko's engineering makes the difference.

Why Scaling Cannabis Production Stalls at the Infusion Stage

Growth in the cannabis sector often exposes the fragility of manual workflows, and nowhere is this more apparent than in the infusion stage. While grinding and packing have largely been solved by existing industrial machinery, infusion remains the most technical and labor-heavy part of the workflow.

This specific bottleneck is where production scaling usually breaks down, turning what should be a profitable expansion into a logistical nightmare, a reality reflected in recent operator surveys showing that only 24.4% of U.S. cannabis businesses are currently profitable due to operational inefficiencies.

The Labor Multiplication Problem in Manual Infusion

Manual infusion requires skilled hands and intense concentration. Each worker on your line brings their own unique technique, their own pace, and unfortunately, their own margin of error. When you are small, this variability is manageable, but scaling production manually means multiplying that variability across every new hire. A process that works flawlessly with two trusted technicians often falls apart completely when you try to replicate it with ten different employees.

This labor dependency creates several compounding problems. Human fatigue is unavoidable; hand infusion demands precision that naturally degrades over a shift. By the sixth hour, even the best technician's accuracy wavers.

Additionally, training bottlenecks slow down expansion. It can take weeks for a new hire to reach an acceptable level of speed, and in an industry where turnover is high, you are constantly paying to train workers who may not stay. Ultimately, each additional worker introduces another source of inconsistency, making true standardization impossible.

Concentrate Waste and Margin Erosion

Beyond the labor challenges, the financial impact of manual inefficiency hits hard on the materials side. Premium concentrates like live rosin, liquid diamonds, and full-spectrum distillates represent significant input costs. These are not materials you can afford to waste.

In a manual setup, specific inefficiencies drain your bottom line. Hand application inevitably leads to spillage during transfer and injection. Workers often over-dose products to ensure potency targets are met, costing you money on every unit, or they inadvertently under-infuse, leading to weak products that disappoint consumers.

When you are running high-volume production, material waste compounds. Spilling a tiny amount of live rosin might not matter on ten joints, but when you are producing thousands a day, that waste erodes profitability to a dangerous degree.

Quality Control Becomes Impossible at Volume

Perhaps the most critical risk of scaling manually is the inability to maintain quality control. When production volume increases, manual QC simply cannot keep pace. In a low-volume setting, a lead technician can inspect every pre-roll. At commercial scale, checking every single unit by hand slows output to a crawl, creating a new bottleneck.

As a result, operators are forced to skip checks, allowing defects to slip through. Issues like clogged airflow, resulting in unsmokable product, or uneven infusion that causes "canoeing," damage the brand reputation. A single bad experience can turn a loyal buyer away forever. Without automation, you are often forced to choose between sacrificing throughput to maintain quality or sacrificing quality to hit your numbers.

Can't I just hire more technicians to solve the scaling problem?

While hiring more staff increases theoretical output, it exponentially increases variability and management overhead. Manual scaling reaches a point of diminishing returns, where the cost of training, managing, and correcting errors for a large team outweighs the revenue generated. Automation provides a stable baseline that labor simply cannot match at volume.

How Jiko's Modular Automation Unlocks Production Scalability

To solve these challenges, Sorting Robotics engineered Jiko with a core philosophy of modularity. The goal was not just to build a machine that works fast, but to build a platform that adapts to the shifting needs of a growing cannabis brand.

Interchangeable Infusion Wheels for Multi-SKU Flexibility

The heart of Jiko’s versatility lies in its infusion wheel system. The machine ships with three infusion wheels, each capable of holding 20 finished pre-rolls for batch processing. This isn't a "one size fits all" approach. The wheels are interchangeable to fit various joint and blunt diameters, whether your brand produces slim half-gram dogwalkers, standard one-gram joints, or oversized blunts.

Jiko adapts to your product rather than forcing you to change your product to fit the machine. Switching between these product lines takes minutes, not hours. This rapid changeover capability is essential for modern cannabis brands managing diverse product portfolios. You can run a batch of mini-joints in the morning and switch to blunts in the afternoon without tool-intensive downtime.

Touchscreen Interface for Custom Infusion Profiles

Control is central to scalability. Jiko places that control directly in the operator's hands through an intuitive touchscreen interface. This system allows for granular adjustment of all infusion parameters, including temperature control to accommodate viscosity differences and air pressure to fine-tune injection levels.

Crucially, these settings can be saved as custom profiles. If you have a specific strain of live rosin that requires a precise temperature and injection speed, you can save that profile. The next time you run that SKU, the operator simply loads the profile. This eliminates the need to "re-dial" the machine for every run, ensuring repeatable production shift after shift.

Built-In Camera for Remote Production Monitoring

As operations scale, managers cannot be everywhere at once. Jiko addresses this with a built-in camera that streams the infusion process in real time. This feature transforms production oversight by enabling remote monitoring via Wi-Fi or Ethernet.

This allows immediate troubleshooting without standing over the machine and empowers effective shift management, enabling a single supervisor to monitor multiple machines or shifts from anywhere in the facility.

How difficult is it to switch the machine between different pre-roll sizes?

Switching SKUs on Jiko is designed to be a rapid process. By simply swapping the infusion wheels to match your new joint or blunt diameter and selecting the corresponding pre-saved profile on the touchscreen, an operator can change over the entire line in minutes, minimizing downtime between different product batches.

Scaling Throughput to 1,000+ Infused Pre-Rolls Per Hour with Jiko

Talking about scale eventually comes down to numbers. The difference between a hobbyist operation and a commercial powerhouse is throughput.

Single Operator Efficiency at Commercial Volume

The most dramatic shift Jiko introduces is the collapse of the labor pyramid. In a manual setup, hitting a target of 8,000 joints a day might require a small army of workers. With Jiko, a single operator running a single machine can achieve a throughput of more than 1,000 infused pre-rolls per hour.

This allows a single trained worker to match or exceed the output of an entire manual infusion team. The operator’s role shifts from laborious handwork to a supervisory capacity, focusing on loading the machine, monitoring the interface, and performing quality verification rather than repetitive motion.

Batch Loading That Minimizes Downtime

Jiko achieves this high throughput through a smart batch-loading system designed for a continuous rhythm. Each infusion wheel holds 20 pre-rolls. Because the machine includes three wheels, the operator can establish a rotation that minimizes downtime. While one wheel is inside the machine being infused, the operator is unloading the previous batch and reloading the next one.

To further speed up this cycle, Jiko includes a pre-roll ejector that streamlines the removal of finished products. This continuous operation replaces the stop-start nature of manual cycles, creating a predictable flow of finished inventory that makes planning and logistics significantly easier for the entire company.

Does the 1,000+ per hour throughput require multiple operators?

No, the 1,000+ throughput figure is achievable with a single operator. The machine's batch rotation system allows a single person to load, unload, and continuously monitor the process. Adding a second person for material prep can further improve efficiency, but the core throughput is designed for single-operator efficiency.

Precision Dosing Across Concentrate Types for Consistent Cannabis Products

Volume is meaningless if the contents of the package are inconsistent. In the infused pre-roll market, the complexity of concentrates, varying viscosities, textures, and behaviors, is the enemy of consistency.

Temperature and Pressure Control for Viscosity Management

Concentrates are not created equal. A high-terpene distillate flows very differently from a thick, cold-cured live rosin. Jiko solves this with precise environmental controls, maintaining an operating temperature within a 65°F to 90°F environment while using internal heating elements to manage flow.

Operators can adjust for viscosity by setting higher temperatures for thick rosin or lower pressure for thin distillate. By regulating the infusion environment, Jiko ensures a consistent injection force every time. This prevents the common issues of "canoeing" or uneven burning caused by globs of cold concentrate sitting in the center of a joint.

Full-Spectrum Concentrate Compatibility

Premium brands are increasingly moving toward full-spectrum products, and Jiko is built to handle the materials that define the top shelf. The system is not limited to just distillate; it is fully compatible with:

Distillate

Live Rosin & Live Resin

Liquid Diamonds

Budder, Badder, & Wet Badder

Sauce & HTE

This broad compatibility protects your investment, ensuring that as consumer tastes shift from high-potency distillates to flavor-rich solventless extracts, your machinery remains relevant. You can have a "Classic" line using distillate and a "Reserve" line using live rosin, all produced on the same Jiko unit.

Programmable Dosing from 50mg to 1,000mg

Flexibility extends to potency as well. Jiko offers programmable dosing capabilities ranging from 50mg to 1,000mg per pre-roll. This wide range opens up massive market segmentation opportunities. You can produce light-dose wellness joints with 50mg to 100mg of infusion for new consumers, or dial the machine up to create high-potency products with 500mg to 1,000mg of concentrate for experienced users.

This programmable precision eliminates the guesswork. In manual infusion, "eyeballing" a half-gram of wax is incredibly difficult. With Jiko, you set the target, and the machine delivers it. This ensures that your label claims are accurate and your customers get exactly the experience they paid for.

Can Jiko handle thick or "crash-prone" concentrates like Live Rosin without clogging?

Yes, Jiko is specifically engineered for high-viscosity materials. The combination of precise temperature regulation to maintain flow state and pressure control ensures that even thick concentrates like Live Rosin or badder can be injected smoothly without clogging the needles or degrading the delicate terpenes.

Reducing Labor Costs While Scaling Cannabis Production Quality

By replacing a high-burnout manual process with a stable automated one, you fundamentally change the margin structure of your products.

From Multi-Worker Crews to Single Operator Stations

Jiko effectively replaces the need for multi-person infusion teams. Instead of managing a crew of five, eight, or ten workers to hit your volume targets, you consolidate that labor into a single operator role.

The savings here multiply quickly. You are immediately reducing payroll by cutting wages, taxes, and benefits. You also gain training efficiency, as you only need to invest in training a few skilled operators rather than a revolving door of entry-level staff. Consequently, supervisors can shift their focus to facility optimization rather than micromanaging the technique of a dozen hand-rollers.

ROI Timelines That Justify Automation Investment

For most Sorting Robotics customers, the return on investment is rapid. Typical ROI recovery occurs in under 12 months, a timeline that is exceptionally fast for industrial capital equipment.

How does automation impact the training requirements for my production staff?

Jiko significantly reduces the training burden. Instead of teaching manual dexterity and "feel" for infusion, which takes weeks to master, you train operators on machine loading and interface navigation. This makes it easier to bring new staff up to full productivity in days rather than months.

Integrating Jiko's Modular Automation Into Existing Cannabis Workflows

One of the biggest hesitations regarding automation is the fear of disruption. Will I have to rebuild my facility? Will I need to hire electrical engineers? Jiko was designed with the reality of active production floors in mind, ensuring that integration is as low-friction as possible.

Compact Footprint for Production Floor Flexibility

Industrial equipment often demands industrial space, but Jiko is surprisingly compact. Measuring just 48" W x 24" D x 66" H and weighing only 110 lbs, the machine fits easily into existing production layouts without requiring major renovations. It is designed to slide into your current workflow, not force you to build a new room around it. This mobility is crucial for growing companies that are constantly optimizing their layouts.

Standard Power and Connectivity Requirements

There is no need to call an electrician to run high-voltage lines. Jiko operates on a standard power cord drawing 1200W at 110VAC. It plugs into a regular outlet, making it a true "plug and play" solution. Additionally, the machine features a built-in air compressor, eliminating the headache of running pneumatic lines throughout your facility. Even with this integrated power, the machine operates at a remarkably low noise level of 56 dB, ensuring a comfortable environment for your production team.

For connectivity, Jiko requires a WiFi or Ethernet connection. This connects the machine to LAKA, Sorting Robotics' production data software, enabling analytics and over-the-air software updates without specialized electrical infrastructure.

Maintenance Simplicity and Dedicated Support

Keeping Jiko running is straightforward. The machine requires a light daily cleaning routine using supplies included in the Customer Kit. Scheduled maintenance intervals are designed to prevent unexpected downtime and ensure the robot remains a reliable workhorse.

Sorting Robotics supports this reliability with a partnership approach. Every Jiko customer gets a dedicated Slack channel that connects their operators directly to support engineers. This isn't a generic help desk ticket system; it is direct access to the experts who built the machine.

Do I need to upgrade my facility's electrical or pneumatic systems to install Jiko?

No facility upgrades are typically required. Jiko runs on standard 110VAC power (a regular wall outlet) and has its own internal air compressor. This "plug-and-play" design means you can install it in almost any existing production room without hiring electricians or running new air lines.

When to Scale Your Cannabis Production with Automated Infusion

Timing is everything. Automating too early can tie up capital; automating too late can cost you market share. Understanding the signals of your production capacity helps you make the strategic decision to scale before you hit a wall.

Signals Your Manual Process Has Hit Capacity

Certain patterns serve as clear indicators that manual infusion has reached its limits. If you find that labor costs are exceeding product margins on your infused SKUs, or if quality complaints are rising despite adding more QC staff, your process is no longer viable.

Other red flags include orders going unfilled due to production bottlenecks or high worker turnover, disrupting your ability to maintain consistency. If you notice premium concentrate waste eroding your profitability, these signals indicate that your operation has outgrown manual methods and is ready for the stability of automation.

Scaling Before the Crisis Point

The best time to automate is before you are desperate. Operators who scale proactively can maintain quality throughout their growth phases. Those who wait until the crisis point often have to sacrifice consistency just to catch up with orders.

Proactive automation with Jiko allows you to smooth out the growing pains. Because the system is modular, you can grow into your capacity over time, ensuring that your team is trained and your profiles are dialed in before the peak season rush hits. Investment timing affects ROI velocity; getting the system in place while you have the breathing room to optimize it ensures that when the demand spikes, you are ready to capitalize on it instantly.

What is the minimum production volume where Jiko becomes cost-effective?

While every business model differs, automation typically becomes a clear advantage once you consistently exceed 5,000 to 10,000 infused pre-rolls per month. At this volume, the costs of manual labor, waste, and inconsistency usually exceed the monthly financing cost, making Jiko's ROI positive very quickly.

Start Scaling Your Infused Production Today

Scaling cannabis production does not have to mean accepting chaos or lower quality. The transition from manual infusion to automated precision is the step that separates craft brands from market leaders. With the ability to produce over 1,000 infused pre-rolls per hour with a single operator, Jiko changes the labor equation entirely.

Its compatibility with full-spectrum concentrates and precision dosing ensures your quality scales right alongside your volume. With ROI timelines often under 12 months and a design that fits seamlessly into your current floor plan, the barrier to entry is lower than ever. Jiko is in stock and ready to ship. Contact us today to schedule a demo and see how Jiko can transform your production.

Frequently Asked Questions

Why do infused pre-rolls burn unevenly?

Uneven burning, often called "canoeing," is typically caused by inconsistencies in the pre-roll's density or the uneven distribution of the concentrate. When infusing manually, it is difficult to center the oil perfectly every time. Jiko eliminates this issue by using a robotic needle to inject a precise core of concentrate directly into the center of the pre-roll, ensuring a symmetrical burn from start to finish.

What is the difference between injecting and painting pre-rolls?

"Painting" involves brushing concentrate on the outside of the paper and often rolling it in kief. While visually appealing, this method can be messy, sticky to handle, and lead to a harsher smoke as the oil burns on the outside wrapper. Jiko's injection method places the concentrate inside the flower, preserving the terpenes, improving flavor, and creating a cleaner, more potent smoking experience without the mess.

How does automated infusion ensure consistent potency?

Manual infusion relies on "eyeballing" or imprecise measurement, leading to significant batch variance. Jiko utilizes precision metering pumps controlled by software to deliver an exact dosage (programmable from 50mg to 1,000mg) to every single unit. This ensures that every pre-roll meets compliance standards and delivers the exact potency stated on your label.

What maintenance is required for a pre-roll infusion robot?

Contrary to the belief that robots are high-maintenance, Jiko is designed for the production floor. Routine maintenance primarily consists of a light daily cleaning using standard supplies like isopropyl alcohol (IPA) and swabs to keep the needles and surfaces clean. The machine is built with industrial-grade components intended for heavy daily use, minimizing the need for complex service.

Can automated machines infuse blunts and hemp wraps?

Yes, provided they are modular like Jiko. Jiko's infusion wheels are interchangeable, allowing operators to swap out standard joint wheels for ones designed to hold larger-diameter blunts or hemp wraps. This flexibility allows brands to expand their product lines to include premium infused blunts without purchasing a separate machine.