Integrating Robotics for Efficient Cannabis Packaging Lines

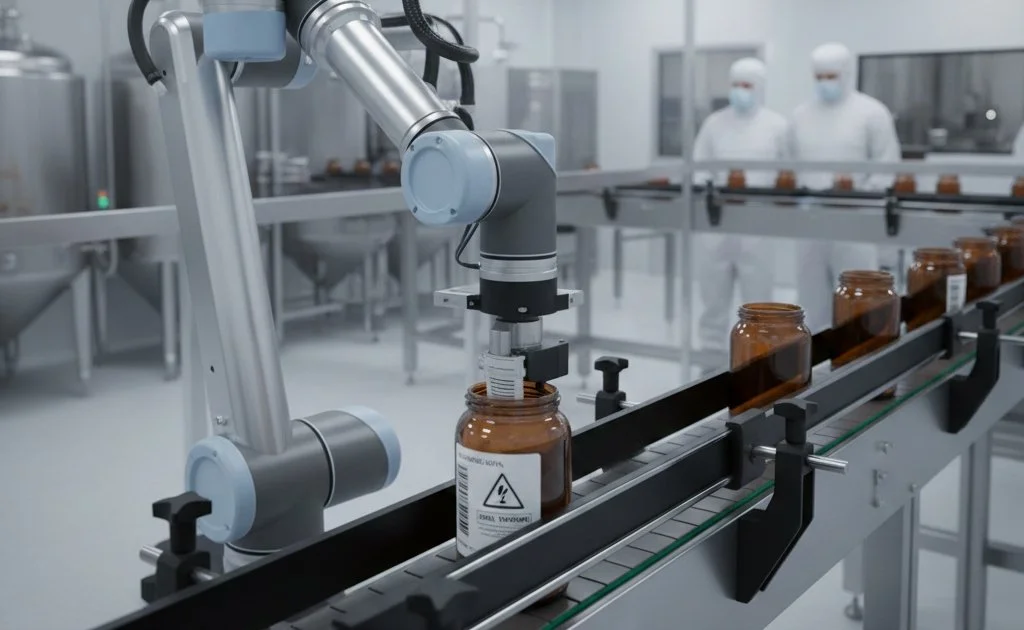

Cannabis packaging has evolved rapidly as production volumes have increased and regulatory requirements have become more demanding. Manual packaging processes that once supported small operations now struggle to deliver the consistency, accuracy, and throughput required in today's highly regulated cannabis market. Manufacturers must balance speed with precision, making automation an increasingly important part of modern packaging strategies.

A 2025 Smart Manufacturing study by Deloitte reports that manufacturers implementing automation are seeing up to a 20% increase in production output and employee productivity, with nearly half of industry leaders ranking process automation among their top investment priorities. These insights reflect the growing need for reliable, repeatable packaging workflows, particularly in the cannabis industry, where compliance and product consistency are non-negotiable.

Rather than replacing entire operations, robotics delivers the greatest value when integrated into targeted stages of the packaging process. When applied strategically, automation reduces human error, improves uniformity, and supports scalable growth without disrupting existing workflows.

This blog explores how robotics enhances the efficiency of cannabis packaging and how manufacturers can realistically and effectively adopt automation.

Why Cannabis Packaging Lines Need Robotics Integration

Cannabis packaging operations face pressures that manual systems struggle to manage effectively. Regulatory precision, delicate products, and variable production volumes create an environment where small inconsistencies can lead to compliance risks, waste, or bottlenecks. Robotics integration introduces structured automation that improves control, repeatability, and overall production stability, making it easier for packaging lines to scale responsibly.

Research on industrial automation strongly supports this approach. A 2025 case study published in paperASIA examined the impact of automation technology on production productivity and found that automation significantly increased batch output, production volume, and operational efficiency while simultaneously reducing total labor time and employee workload.

Although the study focused on the aromatic chemicals industry, the findings are highly relevant to cannabis packaging, where batch-based production, precise dosing, and labor-intensive workflows are common.

Managing Regulatory Complexity

Cannabis packaging requires precise execution of labeling, sealing, and batch-tracking processes. Robotics helps standardize these tasks by performing them consistently across every unit. This reduces the likelihood of human error, missing compliance elements, or inconsistent documentation, especially as production volumes increase.

Improving Operational Efficiency

Manual packaging workflows often slow down as labor fatigue sets in or staffing fluctuates. Robotics systems operate at a steady, predictable pace, automating repetitive tasks that would otherwise limit throughput.

In upstream processes such as sorting and grading, AI-vision & sensor system consulting for cannabis sorting helps operators select the right hardware to reduce variability, improve throughput, and ensure only compliant, high-quality material enters the packaging line. As demonstrated in the automation case study, reducing manual intervention directly improves productivity while shortening total production time.

Supporting Scalable Growth

As cannabis demand grows, packaging operations must increase output without proportionally increasing labor. Robotics provides a scalable foundation that allows manufacturers to handle higher batch volumes while maintaining consistent quality. By reducing labor dependency and improving batch efficiency, automation supports long-term growth without requiring full workflow redesigns.

Does automation reduce the need for skilled workers in packaging operations?

Automation reduces repetitive manual labor but still relies on skilled operators for oversight, quality control, and system management. The goal is not workforce elimination, but improved productivity and reduced physical strain.

Improving Consistency and Reducing Manual Errors

Consistency is one of the most difficult challenges in cannabis packaging, especially as production volumes increase. Manual processes naturally introduce variation due to fatigue, shift changes, and differences in handling technique. Robotics eliminates much of this variability by executing packaging tasks using fixed parameters, controlled motion, and repeatable workflows.

Eliminating Human Fatigue

Unlike manual labor, robotic systems do not experience fatigue or performance drift over long production runs. This allows packaging accuracy, seal quality, and handling precision to remain consistent throughout the entire shift, even during peak production periods or extended operating hours.

Protecting Product Integrity

Cannabis products are sensitive to excessive handling and pressure. Automated systems minimize unnecessary contact by moving products through packaging steps in a controlled, predictable manner. This helps preserve flower structure, pre-roll shape, and packaging materials, resulting in a more uniform finished product.

Reducing Rework and Waste

When packaging steps are executed the same way every time, defects such as misaligned labels, improper seals, or damaged products occur far less frequently. Robotics reduces the need for rework and batch corrections, lowering material waste and improving overall production efficiency.

Do robotics help reduce packaging waste?

Yes. By standardizing packaging steps and reducing handling errors, robotics significantly lowers defect rates, thereby reducing damaged packaging and product loss.

Robotics in Infused Pre-Roll Packaging

Infused pre-rolls require far more precision than standard products. Consistent concentrate placement is essential to ensure uniform potency, proper burn characteristics, and a reliable consumer experience. Manual infusion methods are difficult to scale and often lead to uneven dosing, especially at higher volumes. Automation addresses these challenges by applying controlled, repeatable infusion processes.

Precision Infusion with Jiko

Jiko is an automated pre-roll infusion machine designed to create a consistent concentrate core using controlled temperature and pressure. This process allows manufacturers to evenly infuse pre-rolls, producing consistent results across every unit without relying on manual technique or guesswork.

Flexibility Across Pre-Roll Formats

Jiko is compatible with cones, blunts, and straight tubes across a wide range of sizes. This flexibility allows manufacturers to expand their infused product offerings without investing in separate machines for different formats or redesigning their production workflow.

Scaling Premium Products with Jiko+

Jiko+ is designed to support higher volume infused pre-roll production, including donut joints and hash holes, while maintaining consistent infusion quality. It allows producers to scale premium infused formats without relying on manual techniques or additional labor. By automating concentrate placement, Jiko+ helps streamline infused pre-roll workflows and supports more efficient production without sacrificing consistency or product integrity.

What types of concentrates can Jiko systems handle?

Jiko and Jiko+ are designed to work with meltable concentrates such as live rosin, live resin, sauce, distillate, badder, and shatter.

Automating Kief-Coated Pre-Roll Packaging

Kief-coated pre-rolls are premium products where appearance, adhesion, and consistency directly impact brand perception and sell-through. Manual coating methods are slow, difficult to standardize, and often result in uneven coverage and excessive material loss. Automation provides the control and repeatability needed to scale kief-coated production efficiently without sacrificing quality.

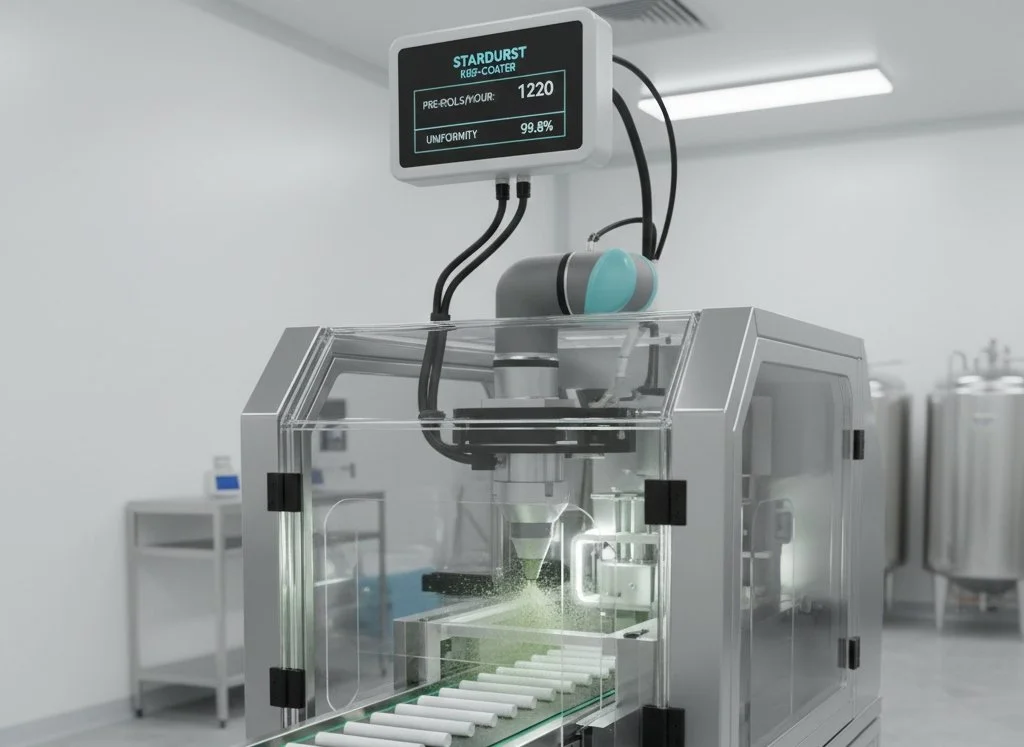

High-Throughput Coating with Stardust

Stardust automates the kief-coating process by applying controlled, repeatable coverage to each pre-roll. Designed for production environments, it supports higher output while maintaining reliable results, allowing manufacturers to meet demand without relying on labor-intensive manual coating.

Reducing Labor and Material Waste

Stardust is designed to operate with a single operator, reducing labor demands compared to manual workflows. Its controlled application process helps limit excess kief loss, supporting more efficient material use while maintaining consistent product quality.

Reliable Adhesion with MoonGlue

MoonGlue was developed specifically to work with automated kief-coating systems like Stardust. It provides strong, reliable adhesion without altering flavor or aroma and can be used in both automated and manual workflows, offering flexibility across different production setups.

How fast can Stardust coat pre-rolls?

Stardust can coat up to 1,500 pre-rolls per hour, depending on configuration and setup.

Precision Filling for Vape Cartridge Packaging

Vape cartridge packaging demands a high level of accuracy and cleanliness. Inconsistent fills not only impact product quality but can also lead to compliance issues and customer dissatisfaction. Manual filling processes often struggle to maintain consistency at scale, making automation essential for reliable, repeatable results.

Accurate Filling with Omni

Omni is a desktop vape cartridge filling machine designed to deliver precise, consistent fills across every cartridge. By electronically controlling fill volumes, Omni delivers consistent fills from batch to batch, reducing variation and product loss.

Efficient Output with Minimal Staffing

Omni fills 100 cartridges per tray in approximately 75 seconds and requires only one operator. This combination of speed and efficiency allows manufacturers to increase output while significantly reducing labor costs compared to manual filling methods.

Seamless Line Integration

With its compact desktop footprint, Omni integrates easily into existing production and packaging workflows. Facilities can add automated filling capacity without major layout changes or extensive downtime.

Is Omni suitable for small or mid-sized vape operations?

Yes. Omni's compact design and single-operator workflow make it well-suited for small, mid-sized, and growing vape operations.

Why Cannabis-Specific Robotics Integration Matters

Cannabis manufacturing presents challenges that standard industrial automation systems are not designed to handle. Product variability, resin buildup, and strict compliance requirements demand solutions built specifically for cannabis workflows. Without this specialization, automation can create more problems than it solves.

Limitations of Generic Automation

Traditional industrial robots are often designed for rigid, uniform products. In cannabis environments, these systems struggle with delicate flower handling, sticky materials, and frequent SKU changes, leading to inefficiencies and increased manual intervention.

Purpose-Built Cannabis Integration

Cannabis-focused robotics integration is designed around real production conditions. Systems are engineered to accommodate specific SKUs, facility layouts, and throughput goals, ensuring that automation enhances existing workflows rather than forcing costly process changes.

Avoiding Hidden Labor Costs

Poorly designed automation often shifts labor rather than eliminating it, requiring operators to compensate for system limitations. Properly integrated robotics reduces manual touchpoints across the line, delivering measurable efficiency gains and a stronger return on investment.

Can poor automation design reduce ROI?

Yes. Poorly integrated systems often require ongoing manual intervention, increasing labor costs and reducing the overall efficiency and ROI of automation.

Building Efficient Cannabis Packaging Lines

Robotics integration is no longer a future consideration for cannabis manufacturers; it is a practical necessity for scaling with control, consistency, and confidence. Cannabis-specific automation transforms packaging lines into predictable, high-performance systems that reduce errors, protect product integrity, and simplify compliance as production volumes grow.

By investing in purpose-built robotic solutions designed for cannabis workflows, manufacturers gain more than speed. They gain operational stability, lower labor dependency, and the ability to expand without sacrificing quality or regulatory accuracy.

If your packaging line is reaching its limits, now is the time to evaluate automation that actually fits your operation. Explore cannabis-focused robotics solutions that scale with your business and deliver measurable results, today and long term.

Ready to upgrade your process? Visit Sorting Robotics to schedule a consultation and take the next step toward smarter, more efficient production.

Frequently Asked Questions

Can robotics be integrated into existing cannabis packaging lines?

Yes. Most cannabis-focused robotic systems are designed to integrate with existing packaging equipment. Modular automation allows manufacturers to upgrade specific stages, such as infusion, coating, filling, or sorting, without replacing the entire production line or causing extended downtime.

Does robotics replace human workers in cannabis packaging?

No. Robotics reduces repetitive, labor-intensive tasks but still requires skilled operators for monitoring, quality control, and system management. Automation is intended to improve productivity and reduce physical strain, not eliminate experienced staff.

Which packaging processes benefit most from automation?

Processes that require precision and repeatability see the greatest benefit. These include infused pre-roll infusion, kief coating, vape cartridge filling, labeling, sealing, and upstream sorting, where consistency directly affects packaging efficiency and compliance.

Is robotics suitable for small or mid-sized cannabis manufacturers?

Yes. Many cannabis-specific automation solutions are designed with compact footprints and single-operator workflows. This makes robotics accessible to small and mid-sized operators looking to scale gradually while controlling labor costs and maintaining quality.

How long does it take to see ROI from cannabis packaging automation?

ROI timelines vary by process and production volume, but many manufacturers begin seeing returns within 12 to 18 months. Reduced labor costs, lower waste, improved throughput, and fewer compliance issues all contribute to faster payback.