Automation for Growth vs Automation for Stability:

Automation serves two distinct functions in cannabis manufacturing by increasing capacity and ensuring consistency. While growth automation focuses on expanding output and capturing market share through higher speed and volume, stability automation prioritizes quality control, precision, and reliability to protect your margins.

Operational success demands a strategic balance between the two. However, prioritizing one over the other without analyzing your specific bottlenecks results in wasted capital. According to the 2025 Vangst Jobs Report, the U.S. legal cannabis industry supported 425,002 full‑time equivalent jobs while retail sales topped $30 billion, highlighting labor’s continued importance and the need for strategic automation to manage costs and operational discipline.

A misaligned strategy, such as investing in speed when quality is lacking or precision when volume is the problem, can stall your progress. In this article, we break down the differences, help you identify your immediate operational needs, and outline how to deploy automation for a definitive competitive advantage.

Why Automation Strategy Matters More Than Automation Itself

Buying equipment requires a clear plan, largely because purchasing high-speed machinery without first fixing inconsistencies in your prep work results in significant production headaches. A fast pre-roll machine fails to pay for itself if the grinding process is inconsistent, just as a precise injection system offers little value if you cannot produce enough units to justify the cost.

The Cost of Automating Without Clear Objectives

Automation without clear goals typically produces poor results. Investing in growth automation before establishing process stability is a common error because high-speed systems require consistent inputs.

Research from the Deloitte Analytics Institute indicates that predictive maintenance strategies can increase productivity by 25%, reduce breakdowns by 70%, and lower maintenance costs by 25%, highlighting the financial risk of operating without a clear plan. Without standard operating procedures (SOPs) and uniform material, these systems just make your existing inefficiencies more obvious, leading to increased downtime and waste.

On the other hand, over-optimizing stable processes during times of high demand limits your ability to capture the market. Spending time perfecting manual techniques while competitors scale with automation results in lost sales. Strategic timing is key, and operators who get this wrong often find their equipment sits unused or they are forced to go back to manual processes because the technology does not fit their daily reality. This is why many successful brands start with robotics consulting services to align their technology with their business goals.

How Strategic Misalignment Wastes Capital in Cannabis Manufacturing

Your equipment must match your operational maturity; growth-focused systems installed in unstable operations will simply make defect rates worse. If manual cone production is inconsistent, a machine capable of filling 2,000 cones per hour will simply replicate those inconsistencies at scale. This ultimately increases material waste and labor costs for fixing mistakes.

Prioritizing stability when demand is surging can also result in missed opportunities. If a distribution contract requires 50,000 units per month, investing in a slow, high-precision lab system rather than production-grade automation creates a bottleneck. Competitive pressure in mature markets and the efficiency standards set by Multi-State Operators (MSOs) demand smart, data-driven decisions.

How often should we review our automation strategy?

You should review your automation strategy quarterly or whenever a significant operational shift occurs, such as entering a new market or launching a new SKU. Technology in the cannabis space evolves rapidly, and a machine that was the best fit 18 months ago might now be a bottleneck compared to newer solutions. Regular reviews ensure your capital expenditure plans align with current market demands rather than outdated projections.

What Is Automation for Growth?

Growth automation is all about speed, volume, and scalability, aiming to maximize output to meet expanding market demand.

Defining Growth Automation in Cannabis Production

Growth automation expands production capacity, supports the launch of new products, and helps you enter new markets. The goal is to increase output without needing to hire a matching number of new employees, assuming your existing processes are already working well enough to be done at higher volumes.

This form of automation fundamentally changes your profit model by allowing you to grow revenue without growing your headcount at the same rate. This is critical in an industry with high labor costs and turnover rates.

Common Applications for Scaling Infused Pre-Roll Operations

Growth automation is essential for scaling infused pre-roll production from small batches to mass-market distribution, as manual labor is simply not enough for statewide distribution models due to physical limits on speed and consistency.

It is also required for introducing complex products like hash holes or kief-coated joints at scale. While manual production works for small drops, producing 10,000 units weekly for a multi-state launch requires systems like the Jiko+ to automate center-hole creation and concentrate injection. Making these premium products by hand at scale is often too expensive to be profitable.

Fulfilling large wholesale orders or distribution contracts requires high-speed solutions. Growth automation enables you to accept volume orders without missing delivery deadlines or burning out your team, while also allowing you to expand quickly into new state markets by replicating proven production lines.

Key Performance Metrics for Growth-Focused Automation

Success in growth automation is measured by speed and capacity. When evaluating these systems, track throughput rates and units per hour (UPH) as your headline metrics. You must also monitor capacity utilization, the percentage of time equipment is active versus idle, and order fulfillment time for bulk requests. Ultimately, the most critical financial metric is revenue per labor hour, ensuring your volume increase does not require a linear increase in staffing. Automated sorting systems can further refine these metrics by ensuring only quality product enters the high-speed line.

Does increasing throughput always lower product quality?

No, but it exposes existing weaknesses. If your inputs are high quality and consistent, growth automation will maintain that quality at speed. However, if your flower grind is uneven or your cones are variable, high-throughput machines will amplify those defects. The drop in quality usually comes from the input material failing to keep up with the machine, not the machine itself.

What Is Automation for Stability?

Stability automation prioritizes control, repeatability, and reducing risk, establishing the solid foundation you need for sustainable scaling.

Defining Stability Automation for Cannabis Manufacturers

Stability automation focuses on reducing variations and eliminating human error, with the primary goal of creating predictable, compliant products. Stability often comes before growth because scaling an unstable process just means you make defective units faster.

This category includes precision dosing systems, computer vision quality control, and automated data logging. These technologies provide a level of accuracy and monitoring that manual processes simply cannot match. For many, this starts with quality assurance robotics to catch errors before they leave the facility.

Where Stability Automation Delivers the Highest Impact

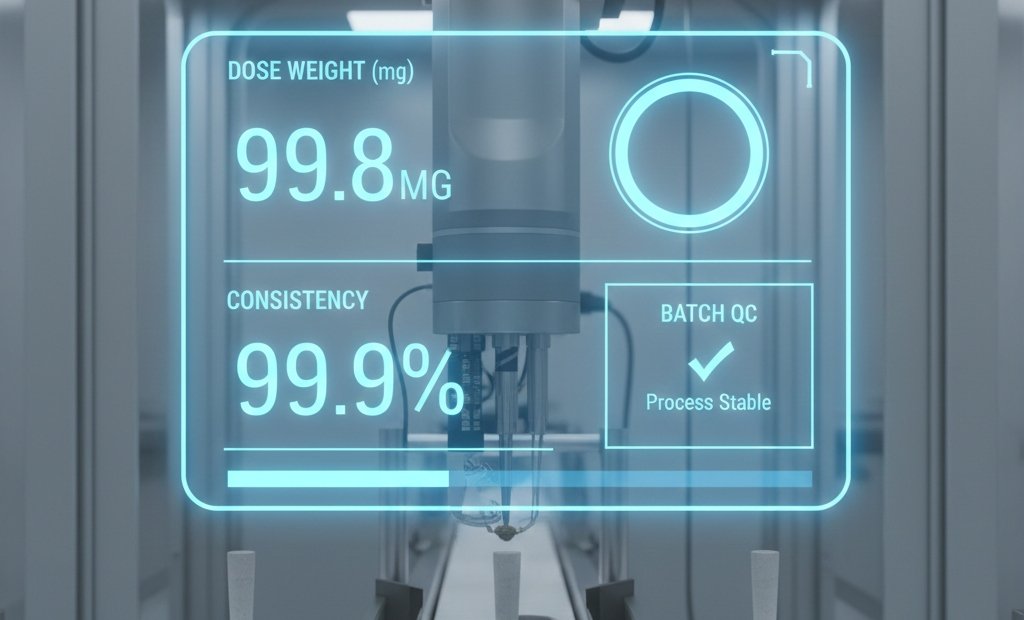

Dosing accuracy for infused pre-rolls and concentrates is a top application because manual injection often results in uneven distribution and compliance failures. Automated injection ensures precise milligram levels, preventing product failures and ensuring a consistent experience for the consumer.

Batch-to-batch uniformity is likewise critical for keeping customers. Stability automation removes the variations that come with manual production, ensuring your product is the same every time.

Compliance tracking and seed-to-sale documentation are also stability functions. Automated systems that log weight, strain data, and batch IDs reduce regulatory risk and paperwork. This is vital because, as demonstrated by MJBizDaily's coverage of the Michigan Viridis recall, regulators can issue wide-scale recalls if testing results are deemed inaccurate or unreliable, freezing months of inventory and forcing retailers to display public safety warnings.

Measuring Success with Stability-Focused Automation

Since success is measured by quality and consistency, validate your investment by monitoring defect rates and rejection percentages, which should drop to near zero. Dosing precision (standard deviation from target weight) and batch consistency scores are also vital. An operator seeing 15% rejection rates due to infusion problems needs precision automation, not higher speed. Reducing rejection rates to near zero increases the amount of product you can sell, which is a gain in capacity achieved through efficiency.

Is stability automation necessary for small-batch craft brands?

Yes, arguably more so than for large brands. Craft brands rely entirely on their reputation for superior quality. A single bad batch or a failed potency test can cause irreparable damage to a boutique brand's image. Stability automation ensures that "craft" means "consistently excellent" rather than "inconsistently handmade," protecting the premium price point that craft brands command.

Key Differences Between Growth and Stability Automation

Understanding this difference is necessary for spending your budget wisely.

Comparing Primary Objectives and Intended Outcomes

Growth automation aims to expand capacity and capture more of the market, whereas stability automation aims to ensure quality and reduce risk. Both deliver a return on investment, but in different ways; one drives revenue up, while the other protects your profit margins.

When Cannabis Operations Should Prioritize Each Approach

Prioritize growth automation when demand is higher than your production capacity. If sales are faster than what you can make, speed is the bottleneck. Conversely, prioritize stability automation when inconsistency impacts your brand reputation or compliance. If product returns or failed potency tests are happening, process control is the issue. Your market position and operational readiness will decide which comes first.

Investment Profiles and Risk Factors for Each Strategy

Growth automation generally involves a larger investment, with payback coming from increased revenue, meaning it relies on the market buying what you produce. Stability automation often requires a lower to moderate investment with fast payback coming from less waste and lower labor costs.

Growth carries risk related to market demand changes, while stability carries lower risk by offering predictable returns through operational efficiency.

Do investors prefer growth or stability strategies?

It depends on the market stage. In a "land grab" emerging market, investors often favor growth strategies that capture market share quickly. In mature, compressed markets, investors look for the operational efficiency and margin protection that stability strategies provide. Showing a clear roadmap that uses stability to de-risk growth is often the most compelling narrative for raising capital.

Signs Your Operation Needs Growth Automation

How do you know it is time to push the accelerator? If your sales team is outpacing your production floor, look for these specific signals that capacity is your primary bottleneck.

Order Backlogs: You consistently apologize to distributors for late shipments or refuse large bulk orders due to insufficient output.

Partnership Refusals: You are declining new retail or distribution agreements because your facility lacks the bandwidth.

Maximum Capacity: Your facility runs full shifts with no physical space or time to add labor, hitting a hard ceiling on manual output.

Market Share Loss: Competitors are seizing shelf space because you cannot restock inventory fast enough.

Missed Premium Opportunities: You cannot launch high-margin SKUs like infused pre-rolls or hash holes because you lack specialized equipment.

Diminishing Labor Returns: Adding more staff creates congestion and slows down workflows rather than increasing total output.

How much buffer capacity should I build in?

Aim for 20% to 30% buffer capacity above your current peak demand. Buying automation that barely meets today's numbers means you will be bottlenecked again in six months. However, buying 500% over capacity ties up capital unnecessarily. A 30% buffer lets you absorb seasonal spikes, such as 4/20, without buying equipment that sits idle for the rest of the year.

Signs Your Operation Needs Stability Automation

Sometimes the problem isn't speed, but consistency. If you are struggling with quality assurance or unpredictable results, look for these red flags that indicate a need for stability. Consumer trust is fragile; industry experts featured in Cannabis Business Times emphasize that brands will never succeed in building a sustained consumer franchise if their products are compromised by inconsistent quality or fail to perform against the brand promise.

Financial Drain from Rejects: A double-digit percentage of your products are unsellable or require rework.

Compliance Risk: Variability across batches increases the risk of failed potency tests, regulatory fines, and costly product recalls.

Eroding Brand Trust: Customer or dispensary feedback indicates noticeable variability in product experience.

Downstream Defects: Quality issues like canoeing or clogging are caught at packaging or by the customer rather than during production.

Key Person Dependency: Production quality depends on specific "star" employees, leaving you vulnerable if they leave.

Data Blindness: You lack accurate, real-time production data, preventing you from identifying root causes of efficiency losses.

Will implementing stability controls slow down production?

Initially, you might see a slight dip as the team adjusts to new protocols, but stability controls actually speed up net production in the long run. By eliminating the time spent on rework, un-jamming machines, and investigating defects, your "uptime" increases significantly. A stable line that runs slightly slower but never stops produces far more than a fast line that is constantly down for troubleshooting.

The Foundation Principle: Why Stability Often Comes Before Growth

It is tempting to chase big volume numbers first, but scaling a flawed process only creates a larger disaster. Physics and economics suggest establishing stability before adding speed.

How Scaling Amplifies Existing Production Problems

A 5% defect rate at 5,000 units is manageable, but at 50,000 units, it becomes a significant financial drain. High-speed environments make minor inconsistencies worse, leading to jams and downtime, which means process stability is a requirement for volume.

The Role of Process Documentation in Successful Scaling

Undocumented processes cannot scale because automation requires precise, repeatable settings. Scaling without stability inevitably leads to inefficiency and lower margins. A robotics integration roadmap helps ensure your documentation matches your mechanical capabilities.

Building the Operational Foundation That Supports Expansion

Successful scaling requires a stable foundation. Your profit per unit must be sound, profitable, repeatable, and high-quality before increasing volume. Stability establishes the protocols that growth automation uses, which is why Sorting Robotics systems integrate stability (precision dosing) with growth (speed) capabilities.

Can experienced staff substitute for stability automation?

Only to a point. Experienced staff are invaluable for troubleshooting and craft, but even the best manual workers experience fatigue. Human error naturally increases over a shift, especially with repetitive tasks like injection or coating. Stability automation provides a level of mechanical consistency that human physiology simply cannot match over an 8-hour or 10-hour production run.

How Growth and Stability Automation Work Together

These strategies are not mutually exclusive. In fact, the most successful operators weave them together to build systems that are both fast and reliable.

Integrated Systems That Deliver Both Speed and Consistency

Advanced automation systems address growth and stability at the same time. The Stardust kief coating machine increases speed to 1,500 units per hour (growth) while ensuring uniform coverage (stability).

Similarly, the Jiko infusion system scales output to meet wholesale demand (growth) while maintaining 0.05g dosing accuracy (stability). This combination ensures volume does not compromise quality.

Production Data as the Bridge Between Scaling and Quality Control

Data tracking supports decisions for both scaling and quality control. Real-time monitoring finds problems immediately, minimizing waste, while historical data helps you plan capacity and calculate ROI.

Phased Automation Strategies for Long-Term Success

Modular systems allow for a phased approach, meaning operations can establish stability first before expanding capacity. This reduces risk and makes the best use of your budget.

Do separate automation systems need to integrate?

Integration is ideal, but not always mandatory immediately. However, isolated islands of automation create "data silos" where you cannot see the full picture of your efficiency. As you scale, ensuring your upstream grinding, mid-stream infusion, and downstream packaging systems can at least share data (if not physical hand-offs) becomes critical for spotting bottlenecks before they become critical failures.

Building Your Automation Strategy: A Practical Framework

Stop guessing and start analyzing. Instead of following trends, use this data-driven framework to decide based on your facility's actual performance.

Auditing Current Operations to Identify Automation Priorities

Start by measuring Throughput & Utilization against your theoretical maximum. Then, rigorously track Defects to calculate the true cost of rework. Identify labor bottlenecks by pinpointing exactly where the line slows down, and assess your Data Capability to ensure you are collecting the metrics needed for informed decisions.

Assessing Market Position and Demand Dynamics

Determine if Demand exceeds Capacity, confirming that production limits are the primary reason for lost sales. Simultaneously, evaluate the Opportunity Cost of missing new product formats or markets due to current equipment limitations.

Evaluating Operational Readiness for Scaling

Verify that your SOPs are clear enough for a machine to replicate and assess if your current Team Capability can manage high-tech equipment. Finally, ensure your System Integration can support scaling without breaking your compliance or inventory tracking workflow.

Prioritizing Investments Based on Operational Reality

If capacity is the limit and processes are stable, prioritize growth automation. If quality is the limit, prioritize stability. If both issues exist, establish stability first, then scale.

Who should lead the automation strategy assessment?

This should be a cross-departmental effort. While the COO or Director of Operations usually leads it, involving your Head of Cultivation (for input material quality) and your Sales Director (for demand forecasting) is vital. Operations needs to know what Sales is promising, and Sales needs to know what Operations can realistically deliver. Excluding either voice leads to the strategic misalignment discussed earlier.

Cannabis-Specific Considerations for Automation Strategy

This industry has unique challenges that generic manufacturing advice often ignores. You must consider these cannabis-specific nuances when building your roadmap.

Compliance and Traceability Requirements in Regulated Markets

Stability automation ensures you stay compliant, whereas growth automation must work with track-and-trace systems to prevent paperwork bottlenecks. Automated data logging reduces audit risk.

Product Format Diversity and Premium SKU Production

Premium formats like infused pre-rolls and hash holes require specialized precision equipment. Stability automation keeps the value of high-ticket items, while growth automation enables mass production of these complex products.

Labor Market Challenges Unique to Cannabis Operations

Automation reduces the impact of high turnover by building process knowledge into the equipment. It reduces reliance on specialized manual labor, making it easier to train staff and move them between tasks.

Margin Pressure and Market Maturity Factors

Mature markets demand efficiency to fight falling prices. Stability automation reduces waste to protect margins, while emerging markets reward speed and capacity. MSOs require standardized systems to ensure consistency across multiple facilities.

How do we future-proof automation against changing regulations?

Focus on flexibility and data access. Regulations regarding packaging, labeling, and potency limits change frequently. Avoid machines that are hard-coded for a single specific format or package size unless they have modular change parts. Furthermore, prioritize systems with software that can easily update dosing parameters or logging requirements, so you are not stuck with hardware that is compliant today but illegal tomorrow.

ROI Considerations for Each Automation Approach

Every piece of equipment must earn its keep. To justify the spend to your partners or board, you need to understand how the math works for each strategy.

Calculating Returns on Growth-Focused Automation

Analyze the revenue increase from higher capacity. Calculate the value of entering new markets and selling premium products.

Calculating Returns on Stability-Focused Automation

Calculate savings from reduced waste, rework, and labor. Factor in lower risk regarding compliance and brand reputation.

Payback Period Expectations for Cannabis Automation Investments

Target payback periods of 6 to 12 months. Stability automation often pays back faster through immediate cost reductions, whereas growth automation returns depend on sales. Integrated strategies typically give the best overall ROI.

What hidden costs are often missed in ROI calculations?

Consumables and maintenance labor are the most frequent omissions. Operators calculate the machine price but forget the cost of specialized cleaning solvents, replacement nozzles, or the technician hours required for weekly deep cleans. Also, factor in the "learning curve" downtime during the first month of installation. A realistic ROI model includes these operational realities rather than assuming perfect performance from day one.

Turn Production Challenges into Competitive Advantages

Growth and stability automation serve different purposes, but the most successful operators leverage both to dominate their market. Stability builds the foundation of quality control that allows growth automation to scale without chaos. You should not have to choose between speed and precision; Sorting Robotics engineered its systems to deliver both simultaneously.

Stop letting bottlenecks dictate your revenue. Whether you need to scale from 5,000 to 50,000 units or eliminate costly rejection rates, the right technology turns production challenges into profitability. Don't just buy a machine; invest in a solution that fits your operational reality. Connect with Sorting Robotics today to map out an automation roadmap that secures your growth and protects your bottom line.

Frequently Asked Questions

Does automating production lower the cost per unit?

Yes, automation significantly lowers unit costs by spreading fixed equipment expenses over a larger volume of output. By reducing variable costs like manual labor hours and material waste from rework, the total cost to produce each joint or package decreases as volume increases. This margin expansion is often the primary driver for ROI in high-growth automation strategies.

Can automated systems handle different product sizes and strains?

Most modern cannabis automation is designed with modularity in mind. Advanced systems allow you to swap out "change parts" to accommodate different cone sizes (e.g., 0.5g vs 1g) or adjust settings for different flower densities and strains. However, switching formats usually requires downtime for retooling, so production managers should batch similar products together to maximize uptime.

Is it better to lease or buy cannabis automation equipment?

Buying offers better long-term ROI and asset ownership, which is valuable for balance sheets. However, leasing preserves cash flow and allows for easier upgrades as technology evolves, which is attractive in the rapidly changing cannabis sector. The choice depends on your current capital liquidity and whether you prioritize immediate cash retention or long-term asset value.

How does automation improve sustainability in cannabis manufacturing?

Automation directly contributes to sustainability by drastically reducing material waste. Precision dosing and filling mean fewer overfilled units and less spillage of expensive flower and oil. Additionally, automated systems often use energy more efficiently per unit produced compared to the lighting and HVAC requirements of a large manual labor force working extended hours to hit the same output.