How Automation Changes Hiring Needs in Cannabis Manufacturing

Cannabis manufacturers adding automation to their production lines aren't eliminating jobs. They are transforming them. Facilities that once relied on large teams for repetitive tasks such as hand-rolling, manual infusion, and packaging are now hiring fewer people with diverse skills.

This aligns with findings from the World Economic Forum's Future of Jobs Report, which anticipates a structural labour market churn of 23% in the next five years, representing a mix of emerging jobs added and declining jobs eliminated. Machine operators, quality control specialists, and automation technicians are replacing traditional trimmer and packer positions

Machine operators, quality control specialists, and automation technicians are replacing traditional trimmer and packer positions. For operations looking to scale without ballooning payroll, understanding this shift is the difference between building a workforce that grows with you and one that holds you back.

Integrating industrial-grade automation into a cannabis facility shifts the primary operational bottleneck from manual labor speed to technical proficiency. This guide details exactly how hiring requirements evolve during this transition and how to build a team capable of managing high-throughput systems.

What Cannabis Automation Actually Replaces on the Production Floor

To hire effectively, you must first understand the specific operational changes that automation introduces. Machines do not simply work faster than humans; they fundamentally change the nature of the workflow by replacing biological variability with mechanical consistency.

This shift is critical for standardization; a study by Deloitte and the Manufacturers Alliance reveals that "Trailblazers, companies leading the way in smart factory adoption, have seen twice the level of gains to labor productivity compared with other peer groups, providing the rigorous consistency required for cannabis compliance and brand integrity.

Repetitive Manual Tasks That Machines Handle Better

The primary targets for automation are tasks requiring high repetition and low variation. In a manual setup, these tasks consume the majority of your labor budget and are most susceptible to human error.

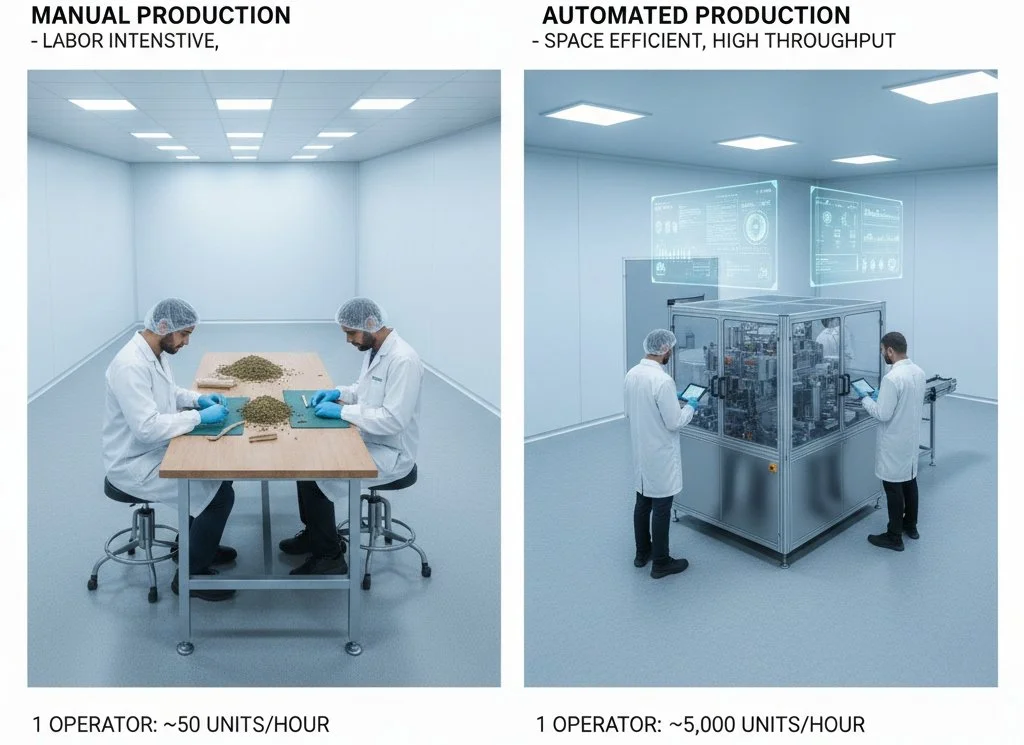

Hand-rolling and cone filling: A skilled worker might produce 100-200 units per shift. In contrast, automated systems can achieve throughputs of 1,000+ units per hour, shattering the physical ceiling of manual production.

Concentrate infusion: Manual infusion often leads to inconsistent dosing and "canoeing." Precision dosing systems eliminate this variability, ensuring every unit meets strict quality standards regardless of the operator's fatigue level.

Kief coating and powder application: Achieving uniform coverage by hand is nearly impossible at scale. Automated kief coating systems ensure a consistent product appearance and potency without the waste associated with manual application.

Packaging and labeling: Robotic packaging lines handle repetitive tasks such as boxing, capping, and labeling. This transition is critical for employee well-being, as data from the Bureau of Labor Statistics (BLS) consistently shows that musculoskeletal disorders (MSDs) account for 31 percent (356,910 cases) of all worker injury and illness cases requiring days away from work, a risk directly mitigated by automating repetitive strain tasks.

Where Human Expertise Still Matters

Automation does not remove the need for human intelligence. It elevates your staff from laborers to operators. Your facility will always rely on human expertise for high-value decision-making.

Recipe development: Machines execute instructions, but your team must define the parameters for flower processing, temperature control, and viscosity management.

Machine calibration: Automation technicians must fine-tune equipment to account for variables such as flower moisture content and oil thickness.

Quality assurance: While machines can detect some errors, quality control specialists are essential for final visual inspections and compliance documentation.

Workflow optimization: Production supervisors are needed to analyze cycle time and batch-processing data to maximize line speed.

Does replacing manual handling with automation affect our brand's 'craft' designation?

Absolutely not; in fact, it often enhances it. True "craft" in cannabis is defined by the quality of inputs (flower, oil) and the recipe, not by the inconsistency of manual assembly. Automation ensures your craft recipe is replicated perfectly every time, preserving the integrity of the flower through precise handling that human hands struggle to maintain across thousands of units.

The Shift from Manual Headcount to Technical Talent

As you integrate pre-roll infusion machines or trimming machines, the composition of your workforce will invert. You will move from a pyramid structure with a large base of general laborers to a more column-like structure of skilled technicians.

Positions Declining in Demand

The roles that decrease are those strictly tied to manual output volume.

Manual trimmers and hand sorters: A trim team of 20+ people can be reduced to 4 to 6 with the right equipment.

Hand-rollers and cone packers: These roles are heavily consolidated.

Basic packaging line workers: Staff focused on boxing or sticking labels will be reduced as you automate cannabis packaging.

General production labor: Any role defined by single, repetitive tasks is a candidate for automation.

Positions Growing in Demand

Conversely, roles focused on maintaining and monitoring systems will see a sharp increase in demand.

Automation technicians: These individuals handle daily machine operation and basic troubleshooting.

Quality control specialists: With higher throughput comes the need for rigorous monitoring of output consistency.

Compliance officers: Managing seed-to-sale compliance becomes more complex as volume increases, requiring dedicated focus on METRC reporting and batch tracking.

Equipment maintenance technicians: Preventive care is critical to avoiding downtime.

Production supervisors: These leaders need technical oversight skills to manage labor allocation and capacity utilization.

How does this shift affect our facility's insurance or workers' comp liabilities?

Shifting to a technical workforce often stabilizes your insurance profile. Manual repetitive motion tasks are the leading cause of Repetitive Strain Injuries (RSI), which drive up workers' compensation claims. While you may need to adjust your policy to cover higher-value capital equipment, the reduction in injury-prone manual labor roles typically lowers the frequency of personnel-related claims.

What Skills to Hire for in an Automated Facility

Hiring for an automated facility requires looking beyond the cannabis industry. The skills that make a great hand-trimmer are rarely the same skills that make a great machine operator.

Technical Aptitude Over Cannabis Experience

We often find that candidates from food manufacturing, pharmaceutical packaging, and beverage production adapt faster than cannabis-only candidates. These industries already operate under strict GMP standards and high-volume pressures. You should prioritize candidates who demonstrate mechanical reasoning and an understanding of how systems work. Ask candidates during interviews to describe how they would troubleshoot a machine that stops mid-cycle.

Digital literacy is also non-negotiable, as operators must be comfortable with digital interfaces like HMI screens and production software. Ultimately, the problem-solving ability to identify root causes of downtime is more valuable than specific strain knowledge.

Core Competencies for Automation Technician Roles

When writing job descriptions for your new automation technician roles, you must focus on specific technical competencies. Candidates need a basic understanding of mechanical systems, pneumatics, and motor operation. They must also demonstrate the ability to strictly follow Standard Operating Procedures and accurately document production data, ensuring SOP adherence. They must also demonstrate the ability to strictly follow Standard Operating Procedures and accurately document cannabis production data to ensure SOP adherence.

Attention to detail is critical for quality monitoring and trichome preservation during automated processes. Furthermore, effective communication skills are necessary for reporting issues to maintenance and supervisors, as well as the physical capability to stand for extended periods and perform routine cleaning and equipment maintenance.

Should we require college degrees for these new technician roles?

Generally, no. While an engineering degree is impressive, practical experience in high-volume manufacturing environments is often more valuable for daily operation. Look for certifications in industrial maintenance, trade school backgrounds, or proven track records in "fix-it" roles. You need staff who aren't afraid to get their hands dirty to keep the line moving, rather than just understanding the theory.

How You Can Train Existing Staff for New Roles

You do not always need to fire your current team and hire a new one. Workforce development through upskilling is often a more efficient path.

Cross-Training as a Retention Strategy

Employees who operate manual processes often possess a deep understanding of your product standards. Transitioning them to technical roles can retain institutional knowledge while boosting morale. A best practice is to train 2 to 3 people per machine to ensure coverage during absences and prevent single points of failure. Framing automation as a career pathway helps retain staff, as moving from a manual roller to a machine operator is a step up in pay and responsibility. These former manual workers often excel at quality checks because they know exactly what a "good" unit looks like.

Building a Practical Training Program

Do not rely solely on "on-the-job" learning. Structure your training to ensure machine proficiency. Basic machine operation training typically takes 1 to 2 weeks, while full proficiency, including troubleshooting and maintenance awareness, develops over 2 to 3 months of supervised operation.

Vendor training: Start with equipment-specific training provided by your automation vendor during installation.

Internal SOPs: Layer in your facility-specific procedures and safety protocols.

Competency checkpoints: Create tests or practical demonstrations before certifying operators to run machines independently.

Quarterly refreshers: Schedule regular training to maintain skills and introduce updates to yield optimization techniques.

External partnerships: Partner with state cannabis workforce initiatives or community college technical programs where available.

How do we assess if a manual worker has the aptitude for technical training before investing time?

Implement a "shadowing" period before formalizing the promotion. Allow manual staff to shadow the installation technicians or lead operators for a few shifts. Observe their engagement: Are they asking "why" the machine works a certain way, or just "which button do I press?" Candidates with genuine technical aptitude will instinctively try to understand the mechanical logic, while others will just memorize the steps.

When Your Facility Is Ready to Change How It Hires

Timing your hiring transition is just as important as the hiring itself. You need to align your workforce changes with your production milestones.

Production Volume Thresholds That Signal the Shift

Below 10,000 units per month, manual labor is usually sufficient, and automation may not yet yield a rapid ROI. The critical evaluation zone is 10,000 to 50,000 units per month; if you find yourself constantly hiring to keep up, it is a sign of a scaling problem that automation could solve. Once you reach above 50,000 units per month, automation becomes essential. At this volume, relying on manual labor exposes you to significant labor costs and inconsistent results.

Warning Signs Your Current Workforce Model Is Maxed Out

Constant overtime without corresponding throughput increases suggests process inefficiency. High turnover is another warning sign; the industry average for repetitive positions approaches 50% annually, so if you are constantly recruiting for entry-level roles, automation offers stability. Quality inconsistencies between shifts or teams indicate that manual processes are failing, while missed deadlines despite full staffing are a clear signal for robotic packaging or infusion solutions. Finally, margin compression, where labor costs eat into margins faster than revenue grows, shows your headcount model is unsustainable.

Is it viable to hire a temporary automation consultant before hiring full-time staff?

It is a viable stopgap for the implementation phase, but not a long-term hiring strategy. Reliance on external consultants for daily operations prevents your internal team from building the "muscle memory" needed for self-sufficiency. If you do hire a consultant, their primary KPI should be how effectively they train your permanent staff to replace them, not just how well they run the machine themselves.

Communicating Change to Your Team

Implementing automation can cause anxiety among staff. Effective change management is crucial to prevent morale drops or sabotage.

Framing Automation as Elevation, Not Elimination

To manage this transition, you must lead with opportunity, emphasizing new skills, career growth, and less physically demanding work. Be transparent about the timeline and which roles will evolve, as uncertainty breeds fear. Identify your high performers early and approach them first to offer access to technical certification and training. Finally, acknowledge concerns directly rather than avoiding the conversation.

Practical Messaging for Your Workforce

Your messaging should explain the "why" by connecting automation to company growth, product consistency, and market competitiveness. Share examples of how employees at similar facilities transitioned successfully to ease fears. Provide clarity on job security for those willing to learn new skills, and create feedback loops so employees can ask questions and raise concerns about the transition.

How do we handle confidentiality if we plan to reduce headcount in the future?

Focus on "natural attrition" rather than layoffs. In the cannabis industry, turnover in manual roles is naturally high. Instead of backfilling every manual role that opens up, freeze those specific hires and open technical roles instead. This allows the workforce to resize organically over a few months, avoiding the morale shock of a sudden layoff and keeping the culture positive for the remaining team.

Turn Your Technical Workforce Into a Strategic Advantage

Automation is the catalyst, but your team is the engine. Cannabis operations that shift from manual labor to technical skills do more than save on payroll. They achieve consistent quality, higher throughput, and predictable margins. Investing in staff who can operate, monitor, and optimize automated systems turns your workforce into a real advantage.

As your facility grows, the question is not whether automation is expensive. The real question is how much manual inefficiency is costing you each month. High-speed pre-roll infusion, precise kief coating, and automated packaging can replace repetitive tasks, reduce errors, and stabilize output if your team knows how to run and maintain these systems.

Sorting Robotics’ solutions such as Jiko and Jiko+ pre-roll infusion machines, Stardust kief coating systems, and modular packaging automation, help you maintain craft-level quality while improving labor efficiency. Schedule a demo or consultation today to see how our equipment can transform your workflow, empower your team, and deliver measurable results.

Frequently Asked Questions

Is automation only viable for large Multi-State Operators (MSOs), or can small craft producers benefit?

Automation is not exclusive to MSOs. While high-speed lines suit high volumes, modular automation enables small-batch producers to scale specific bottlenecks, such as infusion or packaging, without a full facility overhaul. For hiring, this means even small teams need at least one "tech-forward" operator who can manage these modular systems, allowing craft producers to maintain quality while stabilizing labor costs.

Beyond efficiency, how does automation improve workplace safety?

Operational safety improves significantly. Automated systems isolate workers from hazardous processes, such as volatile solvent handling in extraction or fine particulate inhalation during grinding and kief coating. Hiring technicians who prioritize safety protocols ensures these systems are not just efficient but also create a safer environment than manual alternatives.

Do we need a dedicated engineer on staff to run automated equipment?

Typically, no. Modern cannabis automation is designed for machine operators, not engineers. You need staff with mechanical aptitude, someone who can change a belt or calibrate a sensor, but you rarely need a salaried engineer for daily operations. Reliance on a strong vendor support contract often negates the need for high-level engineering headcount.

How does automation change the way we handle production data?

Manual production leaves data on paper logs; automation digitizes it. This shifts your hiring needs toward individuals who are comfortable with data entry and basic analysis. Operators now track uptime, yield rates, and error logs in real-time, requiring a workforce that sees data as a tool for improvement rather than just a compliance chore.