Cannabis Automation ROI & Pilot Planning

The cannabis industry is undergoing a transformative shift driven by the integration of automation technologies, which promise significant improvements in operational efficiency, product quality, and financial returns.

Automation in cultivation and processing leverages technologies such as sensors, climate control, and robotics to optimize growing conditions, reduce labor costs, enhance consistency, and increase yield, ultimately maximizing ROI. Scientific studies highlight that automation not only improves crop yield and quality but also shortens the time to achieve payback on investment.

This guide breaks down how to measure ROI, plan effective pilots, and avoid costly mistakes, giving you a clear framework to decide if and when cannabis automation is the right move for you.

What Is Cannabis Automation ROI?

Cannabis automation ROI is the financial metric that measures the performance of automated equipment compared to manual processes in cannabis production, processing, or packaging. It shows how quickly a business recovers its automation investment through cost savings and revenue increases.

According to Grand View Research (2024), automation in cannabis can boost efficiency by up to 35% and cut labor costs by 20–30%, significantly impacting profitability.

In cannabis, ROI calculations differ from generic manufacturing because they also factor in compliance error prevention, packaging accuracy, and waste reduction, all critical for avoiding regulatory penalties and maximizing margins.

Why is ROI different in cannabis compared to other industries?

Cannabis businesses must track ROI with unique variables:

Compliance fines can exceed $10,000 per violation in certain states.

Product overfill can erode margins by 5–8% per batch.

Delays in packaging or labeling can cause product spoilage or missed sales windows.

Why ROI Is Critical for Cannabis Businesses in 2025

ROI is a survival metric in cannabis due to price compression, high compliance costs, and labor shortages. Automation helps protect profitability by lowering operational costs and increasing throughput without sacrificing quality.

The Cannabis Business Times State of the Industry Report (2024) (link) found that:

63% of operators cite labor costs as their biggest challenge.

42% have already adopted some form of automation.

Companies using automation reported average margin increases of 15% within the first year.

Without automation delivering a strong ROI, operators risk being outcompeted by more efficient producers.

How does automation protect cannabis companies from price compression?

Automation lowers per-unit production costs, allowing companies to stay profitable even when market prices drop, a key advantage in oversupplied markets.

Key Factors That Impact Cannabis Automation ROI

Cannabis automation ROI is shaped by five main factors: labor savings, throughput gains, error reduction, material efficiency, and energy savings. Each directly influences the payback period and profitability.

A National Institute of Standards and Technology (NIST) study shows that precision automation in regulated sectors can reduce waste by up to 18% and improve compliance accuracy by 22%, both of which boost ROI. Each mirrors principles to ensure consistent dosing in vape cartridge filling, where repeatability directly drives ROI.

| Factor | Impact on ROI | Cannabis Example |

|---|---|---|

| Labor savings | Cuts payroll expenses | Automated pre-roll systems replace 3–5 workers |

| Throughput gains | Increases units/hour | Sorting Robotics processes 2,000+ joints/hour |

| Error reduction | Avoids fines and recalls | Vision systems detect mislabeling pre-shipment |

| Material efficiency | Reduces overfill waste | Precision dosing eliminates 0.2g excess per unit |

| Energy savings | Lowers electricity usage | Innovative equipment runs only when needed |

Which factor has the fastest ROI impact in cannabis automation?

Labor savings often provide the quickest ROI because payroll expenses are recurring and reductions appear in the first month of deployment.

What Is a Cannabis Automation Pilot Plan?

A cannabis automation pilot plan is a limited trial designed to test automation equipment in real production before committing to a full rollout. Pilots validate ROI, ensure compliance, and highlight integration issues early.

McKinsey & Company research shows that structured pilot programs reduce project failure risk by 50%. In cannabis, pilots are especially valuable because they assess regulatory fit alongside efficiency gains.

Why not skip the pilot phase and go straight to full automation?

Skipping pilots risks buying equipment that doesn't integrate with workflows or compliance systems, leading to costly downtime, wasted product, and sunk costs.

Steps to Create a High-ROI Cannabis Automation Pilot Plan

To achieve a strong ROI, cannabis automation pilots should follow a structured plan:

Define measurable goals:Example: Reduce pre-roll labor cost by 25% in 60 days.

Choose cannabis-specific automation: Proven performance in similar facilities.

Train staff thoroughly: Use vendor-led training to avoid early downtime.

Benchmark performance before and after: Track units/hour, waste%, rework rates.

Scale after success: Only expand when ROI targets are met or exceeded.

The Harvard Business Review reports that businesses with clearly defined KPIs in pilots are 3x more likely to see long-term ROI from automation. This approach reflects guidance from fast track training tips for new vape filling operators — structured onboarding maximizes ROI from day one.

How long should a cannabis automation pilot last?

Most pilots run 30–90 days to gather enough operational data without delaying full deployment unnecessarily.

Common Mistakes in Cannabis Automation Pilots

Many cannabis companies fail to get the desired ROI from pilots due to avoidable mistakes. The most common are:

Not gathering baseline production data before the pilot starts

Insufficient staff training on equipment

Choosing generic, non-cannabis-specific machines

Failing to align automation goals with overall business KPIs

The U.S. Department of Energy found that inadequate operator training can cut expected automation gains by up to 40%, a costly oversight. Preventive planning is as important as must-have safety features in modern vape fillers, where oversight prevents operational losses.

How can cannabis companies avoid these pilot mistakes?

Develop a pilot checklist that covers training, performance benchmarking, and vendor proof of cannabis-specific success before signing purchase agreements.

Calculating Cannabis Automation ROI Accurately

ROI should be calculated using verifiable data before, during, and after a pilot. Use the ROI formula for your calculation

Example:

Investment cost: $150,000

Annual labor savings: $60,000

Annual waste savings: $15,000

Total annual benefit: $75,000

ROI = 50% in two years (1-year payback if production volume is higher).

What's the average ROI timeline in cannabis automation?

For mid-to-large operators, payback often occurs within 12–18 months, with some high-throughput facilities breaking even in less than a year.

Case Study: Automation ROI in a Mid-Sized Cannabis Facility

A Nevada-based cannabis brand implemented Sorting Robotics' Jiko pre-roll system in its main production site.

Before automation:

8 employees rolling and packaging pre-rolls manually

1,200 joints/day output

$22/hour average labor cost

After automation:

3 employees for oversight and QA

2,500 joints/day output

Consistent product weight ±0.02g

Results:

Labor savings: $164,000/year

Output increase: +108%

Payback period: 10 months

Why did this pilot succeed?

Clear KPIs, vendor-led training, and cannabis-specific system selection ensured smooth integration and maximum ROI.

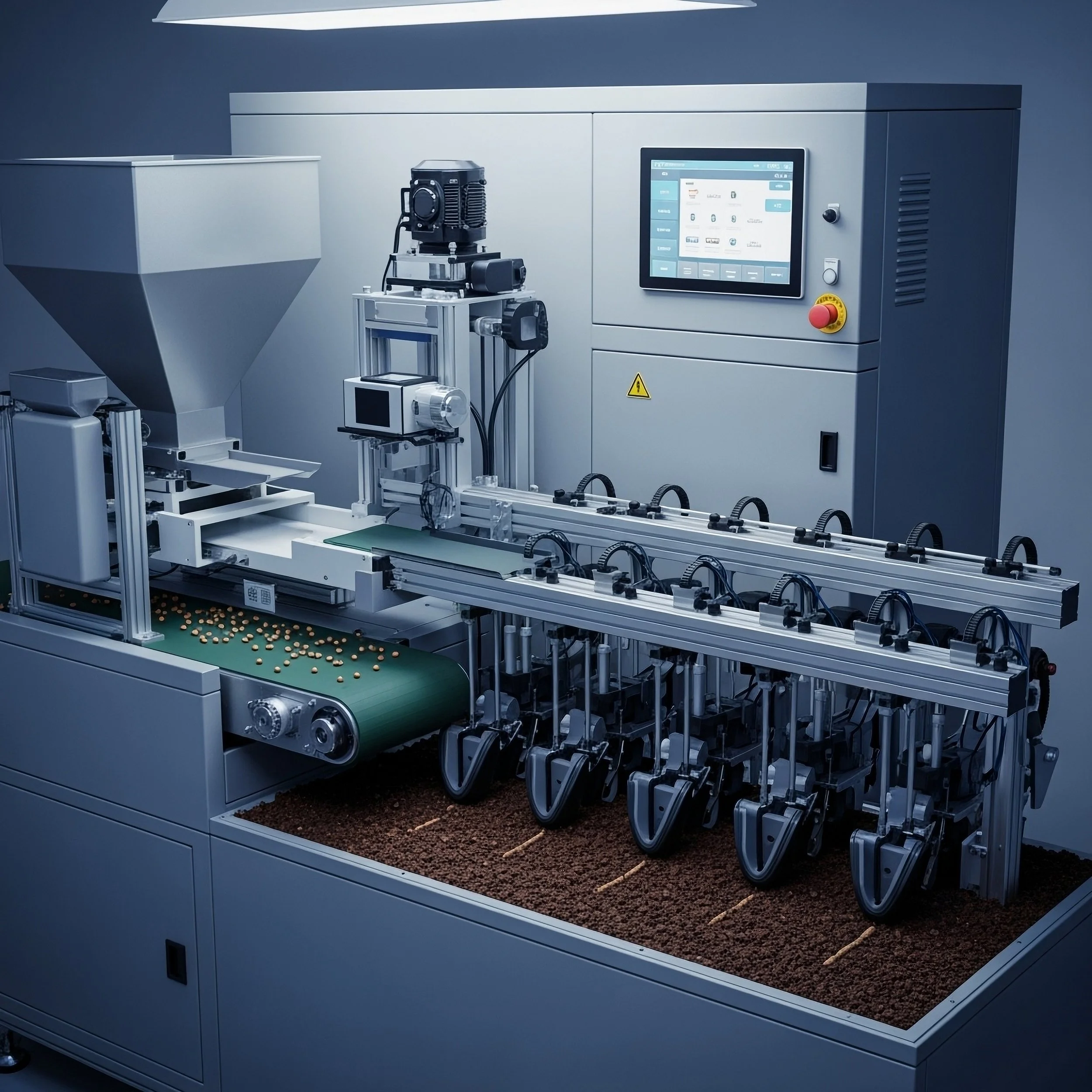

How Sorting Robotics Maximizes ROI for Cannabis Automation

Sorting Robotics focuses exclusively on cannabis automation, offering:

Automated pre-roll filling & packaging: High throughput with minimal waste

Flower sorting systems: Consistent quality control

Label inspection & compliance verification: Reduced risk of costly violations

With cannabis-specific design, their systems integrate with compliance platforms like METRC and BioTrack, cutting training time and ensuring operational compliance from day one. This dedication to cannabis mirrors findings in clean machines prevent vape oil contamination, where tailored designs safeguard ROI and product quality.

What makes Sorting Robotics different from generic automation vendors?

Unlike general manufacturing systems, Sorting Robotics designs for cannabis from the ground up, ensuring precise dosing, regulatory compatibility, and optimal product presentation.

Plan Your High-ROI Cannabis Automation with Sorting Robotics

In today's cannabis market, automation isn't a luxury; it's a competitive necessity. With shrinking margins, growing compliance demands, and labor scarcity, only operators with efficient, automated workflows will thrive. By running a structured pilot, measuring ROI accurately, and choosing cannabis-specific technology, you can scale profitably and sustainably.

Ready to calculate your ROI potential? Contact Sorting Robotics today to schedule a pilot consultation and see how our Robotics Consulting Services can transform your production efficiency.

Frequently Asked Questions

How long does it take to recover the cost of cannabis automation?

Most cannabis operators see payback in 12–18 months, with high-volume facilities breaking even in under a year.

Is automation worth it for small cannabis facilities?

Yes, with the right pilot, even small operations can reduce labor costs and improve consistency enough to achieve positive ROI.

What are the hidden costs of cannabis automation?

Maintenance, software licensing, and operator training are standard additional costs, but these are usually offset by savings within the first year.

How does automation improve compliance?

Automation minimizes human error, ensures precise labeling, and maintains consistent product weights, reducing the risk of regulatory fines.

Should I run multiple pilots before full rollout?

For multi-site operations, yes, pilots in varied facilities help ensure consistent results before scaling automation company-wide.