How Automated Weight Control Reduces Compliance Violations

Accurate weight measurement is a critical part of any production or packaging operation. Small weight errors can lead to compliance violations, fines, and delays that affect both output and costs. Automated weight control helps reduce these risks by keeping product weights within defined limits.

According to the National Institute of Standards and Technology (NIST), accurate weights and measures are a foundation of fair trade and quality control in commercial transactions. Correct measurement standards protect both businesses and consumers by reducing errors and maintaining consistent product quality.

This blog explains how automated weight control supports compliance by reducing weight-related errors and protecting product quality.

How Weight Accuracy Affects Compliance and Product Approval

If a product misses its declared weight, everything from approval to delivery can fall apart. Regulators rely on accurate weights to confirm that products meet legal and quality standards. When weight accuracy declines, companies face delays, increased review volume, and a higher risk of compliance issues. Implementing quality assurance robotics cannabis manufacturing protocols can mitigate these risks by providing constant, digitized oversight.

Here are the main compliance factors linked to product weight.

Government Weight Regulations

Many countries enforce laws that require products to meet their declared weight. These rules protect consumers and ensure fair trade between businesses. Regulators use inspection standards and testing procedures to verify that products meet weight limits. When companies stay within these limits, products move through regulatory checks with fewer delays.

Inaccurate Weight Risks

Weight errors can lead to serious compliance problems. Products that fall outside allowed limits may trigger investigations, shipment holds, or forced corrections. Even slight weight differences can raise concerns when they appear across large volumes. Consistent weight accuracy helps companies avoid these risks and keep approvals on track. This is particularly vital when you scale cannabis business robotic packaging 2025, as high-speed lines require instantaneous error detection.

Manual Compliance Gaps

Manual weight checks create uncertainty in regulated environments. People can miss small variations or apply different methods across shifts. This makes it harder to maintain consistent results when regulators review production output. These gaps increase the chance that products fall outside required weight ranges.

How do regulators determine the allowed weight tolerance for packaged products?

Regulators set weight tolerances based on national measurement laws and testing standards. These limits allow small, unavoidable variation while still protecting consumers and ensuring fair trade between buyers and sellers.

How Automated Weight Control Fits Into Modern Production

Accurate weight checks keep production lines moving without unnecessary stops or rework. When products stay close to their target weight, teams avoid delays and maintain a smooth flow of work. Automated weight control supports this process by checking each item as it moves through the line. Robotics integration services allows manufacturers to embed these checks directly into existing workflows.

Here are the main components that enable automated weight control on a production floor.

Automated Weighing Systems

Automated weighing systems measure product weight as items pass through a fixed point on the production line. These systems connect directly to conveyor lines, so products do not need to stop for inspection. Each item passes over the scale, and the system compares its weight with defined limits. This allows teams to identify weight differences early.

Sensors And Checkweighers

Sensors and checkweighers provide the measurement tools that enable automated weight control. Sensors detect each product and capture its weight, while checkweighers confirm that the value falls within an accepted range. Together, these tools give production teams a clear and consistent view of weight across the line.

Reliable Weight Verification

Automated verification ensures that each product receives the same weight check under the same conditions. The system applies uniform rules to every item, providing consistent results from one run to the next. This steady approach helps production teams rely on weight data when monitoring quality and adjusting processes. For specialized products, such as jiko donut maker outputs, precision is key to maintaining the "center-hole" infusion integrity.

Why Manual Weight Control Increases Compliance Risk

Many operations still rely on people to check product weights. Results can vary from one worker to another and from one shift to the next. These differences create gaps in consistency and visibility. Research into industrial quality control reveals that manual inspection accuracy rates often average just 80%, as factors like fatigue and subjectivity cause human operators to miss significant product deviations. When weight accuracy matters for compliance, these gaps increase the chance of errors that slow production and raise regulatory concerns.

These areas show where manual weight control creates risk.

Human Error Impact

People perform many steps during manual weighing, from placing products on a scale to recording the results. Small mistakes at any stage can lead to incorrect records. Over time, these errors add up, making it harder to maintain consistent weight results.

Missing Compliance Records

Manual recordkeeping often results in missing or incomplete entries. Paper forms and spreadsheets can contain gaps, wrong values, or lost information. When teams cannot clearly track every weight result, it becomes difficult to prove that products stayed within required limits.

No Real Time Alerts

Manual processes do not provide immediate notice when a product falls outside its target weight. Staff may not detect problems until much later. This delay allows weight issues to continue longer than they should.

High Speed Inspection Limits

Production lines move quickly, but manual weighing does not keep up. Workers cannot check every item at high speed. As a result, some products pass through without proper weight verification.

How Automated Weight Control Supports Regulatory Compliance

Regulated industries require products to meet declared weight targets. Companies must follow weight rules to avoid penalties and shipment holds. Automated weight control provides teams with a reliable way to check each item and maintain clear records. This approach provides compliance teams with solid proof rather than guesswork or missing paperwork.

Here is how automated systems support compliance on the production line.

Real Time Weight Checks

Automated weight control checks each product as it moves through the production line. The system measures each item and compares the result with allowed limits. This replaces sample-based checks and helps maintain compliance consistency across the entire production run.

Automatic Non-Compliant Rejection

The system removes products that fall outside the target weight range. This keeps incorrect items out of later production stages and final shipments. Early removal reduces regulatory risk and limits customer complaints.

Monitoring And Alert Systems

The system tracks weight results over time and identifies patterns that signal potential issues. When weight values drift outside normal ranges, alerts notify operators. Teams can correct problems before compliance failures appear.

Digital and Audit-Ready Records

The system stores weight results in a digital format with time and product details. Teams can access this data for internal checks and regulatory reviews. Reports show weight results across production runs and provide clear proof of compliance.

Can automated weight records be used as legal evidence during regulatory disputes?

Yes. In many regulated industries, digital weight records from certified systems are accepted as evidence. These records include time, product, and measurement details that help regulators verify compliance with weight rules.

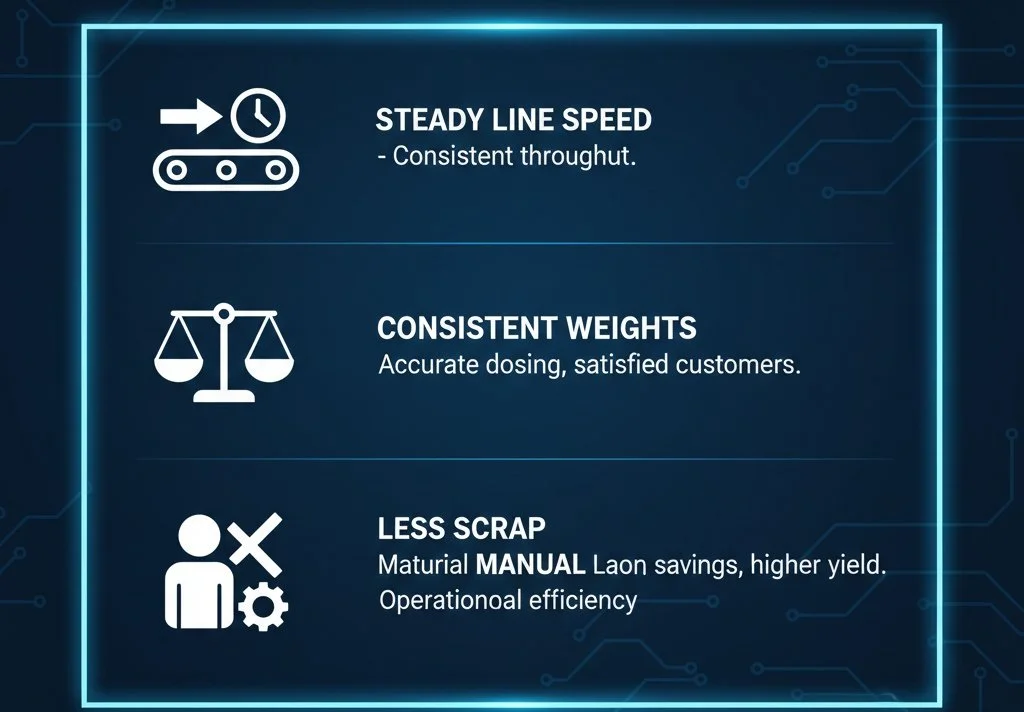

How Automated Weight Control Supports Daily Production

Daily production depends on steady output, fewer errors, and smooth handoffs between each step of the line. Weight mistakes can slow work, create waste, and place extra pressure on staff. Automated weight control helps keep production on track by checking every item and reducing manual tasks that often lead to delays.

These points show how weight automation supports everyday operations across the production floor.

Production Speed And Consistency

Automated weight checks allow products to move through the line without pauses for manual inspection.

Each item passes through a fixed weighing point

System checks the weight at line speed

Results remain consistent across shifts

Output stays steady even during peak volumes

Reduced Product Rejects

Accurate weight checks lower the number of products that fall outside allowed limits.

The system detects weight issues early

Teams remove incorrect items before packing

Fewer products move into rework

Final shipments stay closer to target quality

Lower Material Waste

Better weight control reduces excess material use and scrap.

Products stay closer to their target weight

Overfilled packages decrease

Underfilled items drop

Raw materials last longer

Reduced Labor Pressure

Automation takes routine weighing tasks away from staff.

Workers no longer weigh items by hand

Teams spend less time recording results

Focus shifts to quality checks and equipment care

Workloads become more balanced

Smooth Workflow Control

Weight data helps production teams spot problems early and keep processes aligned.

System tracks trends across runs

Teams see issues before they grow

Adjustments happen faster

Line flow stays stable

Industries That Rely on Accurate Weight Compliance

Different industries must follow strict weight-related rules to meet regulatory and safety standards. When product weights are incorrect, companies face recalls, slower audits, higher costs, and damaged trust. Accurate weight measurement helps companies stay aligned with requirements and maintain steady production, quality control, and customer confidence.

These industries rely on accurate weight compliance to meet regulations, protect quality, and avoid penalties and delays.

Food And Beverage

The food and beverage industry must follow food safety and labeling rules that include accurate product weights. Regulators require packaged foods to match the weight shown on the label. Reliable weight data helps companies control ingredients, keep portion sizes consistent, and pass food safety and labeling checks.

Pharmaceutical Production

Pharmaceutical companies must ensure precise weight measurements for raw materials and finished products to meet strict quality and safety standards. Weight compliance supports requirements in drug formulation and helps companies meet good manufacturing practice guidelines, which demand consistent quality and accurate documentation throughout production.

Logistics And Packaging

Logistics and packaging operations rely on accurate weight data to calculate shipping costs, verify product labels, and pass customs inspections. Regulators often check weight records to confirm that goods match declared weights, helping companies avoid delays, fines, and disputes with carriers or trade partners.

Manufacturing Operations

Manufacturers use accurate weighing to maintain product quality consistency and comply with quality management standards, such as current good manufacturing practices. When weight targets are precise, teams can reduce defects, maintain consistency across batches, and produce reliable product data for internal and external quality reviews.

Key Features That Make Automated Weight Control Reliable

Automated weight control integrates smart tools that monitor product weight as items move through production. These systems help teams spot problems early, keep records accurate, and maintain steady quality without slowing work.

Below are the main features that make automated weight control reliable and effective.

Inline Checkweighers

Inline checkweighers are weighing stations built directly into production lines. These devices measure product weight as it passes, eliminating the need for manual stops or slowdowns. By checking every item, these tools help teams confirm that products meet weight standards. Inline checkweighers provide consistent data for quality teams to review and act on.

Weight Sensors

Weight sensors are the core measurement component of any automated weight system. These sensors measure each item's actual weight and send the data to control systems for analysis. Accurate weight sensors help ensure that measurements do not vary widely from one check to the next. This consistency improves confidence in compliance results.

System Integration

System integration connects weight control hardware with other production equipment and software. When checkweighers and sensors integrate with line controls and reporting systems, teams see weight results alongside production data in one place. Integrated systems reduce the need for manual data entry and make it easier to use weight data for decision-making.

Automated Feedback Loops

Automated feedback loops help production teams respond quickly when weight issues appear. These loops send signals back to the line control system or operators when weight readings fall outside acceptable limits. This allows teams to take corrective action without waiting for manual inspection or delayed reports. It reduces the risk that weight issues will recur over time.

Why Automated Weight Control Supports Long-Term Success

Companies invest in automated weight control because it protects more than daily production. Over time, accurate weight checks support compliance, customer confidence, and steady business growth. When weight data stays reliable, teams make better decisions and reduce risks that can hurt operations, finances, and brand image.

These areas show why automated weight control adds lasting business value.

Reduced Regulatory Fines

Weight rules apply across many regulated industries. When products meet declared weight targets, companies avoid penalties and corrective actions. Automated systems consistently check weight, helping teams stay within legal limits and reduce the risk of fines.

Customer And Partner Trust

Customers and business partners expect products to meet stated weight and quality standards. Reliable weight control helps companies deliver consistent results. This builds confidence that products meet expectations and that operations follow clear quality practices.

Strong Brand Reputation

A strong brand depends on dependable product quality. Weight accuracy supports this by reducing complaints, returns, and disputes. Over time, steady performance improves how customers and regulators view the company.

Market Compliance Pressure

Many industries face increasing regulatory oversight and customer scrutiny. As rules tighten, companies must prove that their processes remain in control. Automated weight control helps meet these expectations by keeping clear records and consistent checks.

Future Ready Operations

As production volumes grow and regulations evolve, manual weight checks become more complicated to manage. Automated systems scale more easily and support modern data-driven operations. This prepares companies for future compliance needs without adding unnecessary workload.

How quickly can companies see financial benefits after moving to automated weight control?

Many companies begin to see savings within months through fewer fines, less rework, and more stable production. The exact timing depends on production volume, error rates, and the system's integration with existing processes.

Secure Your Production With Automated Weight Control

Accurate weight control is critical for regulatory compliance, consistent product quality, and smooth production. Manual weighing introduces errors that can lead to fines, rework, and shipment delays. Automated systems eliminate these risks by providing real-time weight checks, digital audit trails, and early alerts for deviations.

Sorting Robotics helps manufacturers take full control with solutions like Jiko and Jiko+ pre-roll infusion machines, Stardust kief coating systems, and custom automation with vision-enhanced inspection systems. These systems catch deviations early, reduce waste, and support consistent quality across your production lines, helping you maintain compliance and operational efficiency.

Protect your production and simplify compliance today. Schedule a demo with Sorting Robotics to see how our automation solutions streamline weight control, optimize workflows, and deliver reliable, high-quality output for your facility.

Frequently Asked Questions

How often should automated weighing systems be calibrated to meet regulatory standards?

Most regulations require calibration at set intervals defined by national measurement authorities, often daily checks and periodic certified testing to confirm scales continue to meet legal accuracy limits.

Do different countries apply different legal weight tolerances for the same product?

Yes. Each country sets its own legal metrology rules, so allowed weight tolerances and testing methods can differ between regions, even for the same packaged product.

Are automated checkweighers required to meet any government certification or approval?

In many regions, checkweighers used for legal trade must meet national or regional metrology certification standards that confirm the equipment measures weight within approved accuracy limits.

What happens if a regulator challenges the accuracy of an automated weight system?

Regulators may require retesting, calibration records, or equipment verification. If results fail, companies must correct the system and may face temporary production or shipment restrictions.

Can automated weight control help resolve customer disputes about short-weight shipments?

Yes. Time-stamped digital weight records can show the weight of products at packing or shipping, which helps companies verify claims and respond accurately to customer disputes.