Planning Power, Airflow, and Utilities for Robotics-Driven Cannabis Lines

Modern cannabis facilities often invest in robotics but still face slowdowns, quality issues, and costly rework. The real problem is not the machines. It is weak power, poor airflow, and utilities that were never planned for automation.

A recent research paper on Robotics and Automation in Cannabis Greenhouse Operations shows that automated technologies can reduce labor costs and improve operational precision while standardizing workflows in complex cultivation environments. These systems help manage repetitive tasks under controlled conditions, making them a valuable tool for growers facing labor constraints and quality demands.

This guide shows how small planning mistakes in power and airflow can quietly limit your robots before you even notice a problem.

Why Poor Infrastructure Stops Good Automation

Your automation investment can only perform as well as the facility that supports it. Many cannabis operations install robotics without first planning the building systems, and then face unexpected slowdowns, errors, and unreliable machines. Without proper infrastructure, even good robots Jiko robotics systems struggle to run smoothly and consistently over time.

These infrastructure gaps lead directly to the real problems discussed in the following points.

Robotics Installation Requirements

Robotic systems in cannabis production require more than just floor space to operate effectively. They depend on steady electrical power, clean airflow, and reliable utilities to stay accurate and avoid faults. When these basics are missing or unstable, robots may pause, reset, or require manual support. Planning installation requirements helps match the facility to the machines, so automation such as Stardust automation solutions can run as designed without constant interruptions.

Infrastructure Controls System Uptime

A facility's electrical, airflow, and utility systems determine how often your automation can run without interruption. If power fluctuates, temperatures swing, or essential services like compressed air drop, robots can stop working until technicians intervene. Well-planned facilities lessen these risks, keeping robots running more of the time. Higher uptime means smoother operations, fewer delays, and less pressure on staff to diagnose avoidable stops.

Small Issues Cause Downtime

Minor infrastructure problems can become major operational setbacks. A brief electrical surge, excess dust in the air, or an inconsistent utility supply may seem small, but they can quickly affect sensitive robotics systems. These small issues interrupt production, lead to more manual checks, and reduce overall efficiency. Investing time in facility planning prevents cascading problems, helping cannabis producers maintain steady, predictable automation rather than constantly chasing faults.

Poor Setup Wastes Investment

Without infrastructure planning, your robotics equipment can never operate at its best. Even reliable machines underperform when the environment around them is unstable. This leads to more maintenance, more unscheduled downtime, and more cost than expected. Proper planning aligns your facility to support automation, protecting your investment by reducing repair time, improving machine reliability, and ensuring robots deliver consistent returns over their lifecycle. Custom Integrations and Automation can also help optimize your workflows.

Can existing cannabis facilities be upgraded for robotics, or do they need to be rebuilt?

Most cannabis facilities can upgrade for robotics through electrical, airflow, and layout improvements. Complete rebuilding is rarely needed, unless the building cannot support basic power, safety, or utility requirements.

How Robotics Changes Cannabis Production Requirements

Robotics changes how a cannabis production line works from end to end. When machines replace manual handling, the facility must support steady and controlled operation. Small issues in power, air, or utilities that once went unnoticed can quickly affect automated systems, making planning far more critical than before.

These differences become clear when you compare robotic workflows to manual cannabis production.

Continuous automated production

Robotic systems do not work in short manual shifts. They are designed to run for long periods with minimal breaks. This creates a steady flow of material through the line, which increases the need for stable power and utilities. If a facility was designed for stop-and-start operations, it may struggle to support continuous operation without upgrades.

Precision requires stability

Cannabis robots handle small amounts of product with high accuracy. That precision depends on stable conditions around the machines. Power changes, temperature swings, or airflow problems can affect how sensors and motors perform. When the environment remains controlled, robots can place, fill, and sort more reliably, helping maintain product consistency across every batch.

Sensitive cannabis environments

Cannabis flower and pre-roll materials are easily affected by dust, humidity, and air movement. Robotics moves these materials in ways that can stir particles into the air if the space is not well controlled. Facilities need clean airflow and steady humidity to protect both the product and the machines, maintaining high quality and reducing the risk of contamination.

How Power Supports Cannabis Robotics

Cannabis production systems that use robotics depend on reliable electrical power to stay active and accurate. Robots and their control systems need a steady voltage and the correct type of supply to avoid unexpected pauses or resets. Without careful power planning, even good equipment cannot deliver consistent performance.

These power needs decide how reliable your cannabis automation will feel during real production.

Robotics electrical demand

Robotic equipment uses steady electrical power to operate motors, sensors, and control units. When a facility provides too little power or an unbalanced supply, machines slow down, reset, or stop during critical tasks. Teams must calculate how much power each robot and support system uses and confirm that the electrical system can meet this demand every day.

Three-phase power needs

Many industrial machines, including large robotic systems, use three-phase power because it delivers energy more evenly and supports higher loads. This type of power reduces electrical swings and protects motors from stress. When a cannabis facility plans for a three-phase supply, robotics systems operate more smoothly and face fewer interruptions during daily production.

Backup power systems

Power outages halt robotics operations and often result in lost work or system errors. Backup power systems, such as uninterruptible power supplies, keep equipment active for a short time and allow generators to start or operators to shut down safely. These systems protect sensitive electronics and help production avoid sudden stops during brief outages.

Surge and voltage control

Robotic systems contain sensitive electronic components that are prone to damage from power spikes or voltage drops. Surge protection devices block excess energy during sudden spikes, and voltage regulators keep electricity steady during fluctuations. These tools reduce system faults and help electrical components last longer by protecting them from unstable power conditions.

How often should power systems be inspected when running automated cannabis lines?

Most automated cannabis facilities should inspect power systems at least quarterly, with visual checks more often. Regular inspections help detect wear, loose connections, and voltage issues before they disrupt robotic equipment.

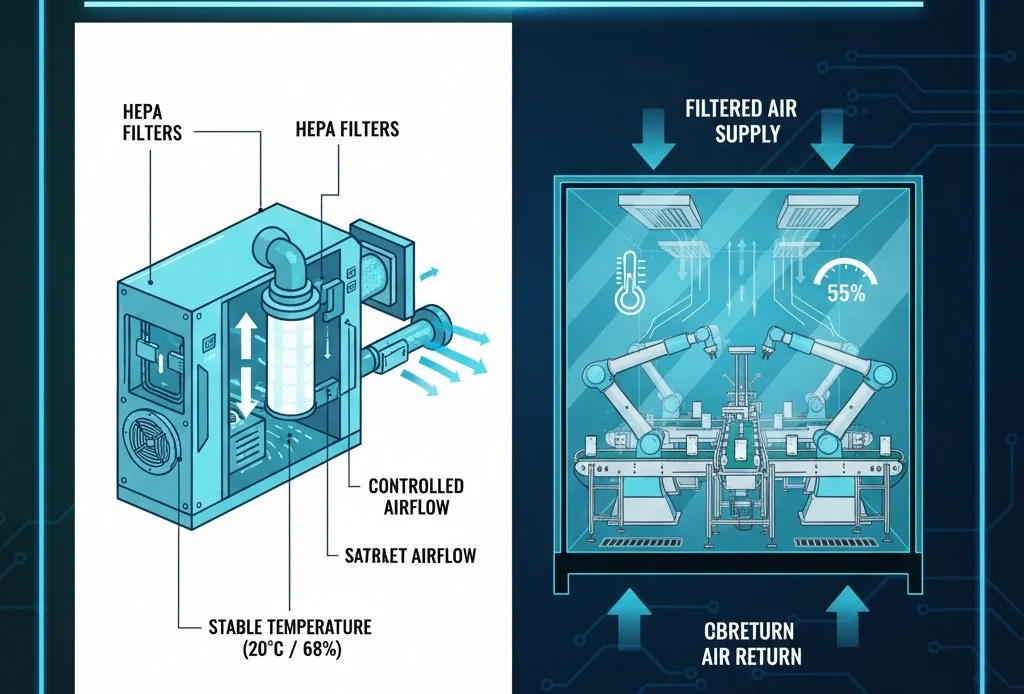

How HVAC Protects Cannabis Automation

When cannabis facilities add robotics, air quality becomes a priority. Automated equipment moves product faster and more often than human hands, which means dust, heat, and moisture can affect both the machines and the flowers. According to research on cannabis cultivation environments, HVAC systems that control temperature and humidity are essential to maintain stable growing conditions that protect plant quality and environmental balance. HVAC systems help keep those conditions under control so automation stays dependable.

These air systems help cannabis robotics operate under steady conditions.

Kief And Dust Control

Cannabis handling releases fine particles into the air, especially when trimming, filling, or transferring flower. Robots move material faster and more frequently than people do, which can increase airborne kief and dust. HVAC systems with proper filtration remove these particles before they settle on machines or products. Clean air reduces buildup on sensors and mechanical parts, which helps robotics operate with fewer interruptions and more consistent results.

Temperature And Humidity Stability

Cannabis materials react to changes in temperature and moisture. When the air is too dry or too humid, flowers can lose quality or become more challenging to handle. Robotic systems also work best in stable conditions. HVAC systems maintain a steady temperature and humidity range, supporting smooth material flow and reliable machine performance throughout each production run.

Clean Production Zones

Automated cannabis lines often include areas for filling, coating, and packaging. These steps require cleaner air than is available in storage or transport zones. HVAC systems help create separate air zones, keeping clean areas protected from dust and outside air. This zoning supports product quality and allows facilities to meet basic cleanliness expectations without adding manual cleaning work.

Airflow Prevents Contamination

Air moves constantly through a cannabis facility. Without control, that movement can carry dust, plant particles, or outside air into sensitive areas. HVAC systems guide airflow in the right direction, pushing clean air into production spaces and moving used air away. This airflow pattern lowers the chance that unwanted particles reach robotic equipment or finished cannabis products.

How Utilities Keep Cannabis Lines Running

Cannabis robots do not work alone. They rely on several behind-the-scenes utility systems that keep every movement, signal, and cleanup process running smoothly. When these systems stay reliable, automation feels effortless. When they fail, even advanced machines struggle to keep production on track.

These utility systems keep cannabis robots working without unnecessary interruptions.

Compressed Air Supply

Many automated cannabis machines use compressed air to move parts, seal packages, and operate small mechanical tools. Without steady air pressure, these actions lose accuracy or stop altogether. A well-sized compressed air system delivers consistent force across the line. This helps packaging, sorting, and handling equipment remain responsive, keeping robotic tasks running smoothly without delays caused by weak or uneven airflow.

Industrial Vacuum Systems

Vacuum systems help remove loose plant material, dust, and small debris that collect during cannabis processing. Robotics moves material quickly, which increases the need for reliable waste and particle removal. Industrial vacuum systems keep work areas and machine parts clear, allowing sensors and moving components to stay clean. This supports steady operation and reduces the need for frequent manual cleaning that can interrupt automated workflows.

Water And Drainage

Cannabis facilities use water for cleaning equipment, washing work areas, and maintaining basic sanitation. Robotic lines require clean surroundings to protect both products and machines. Proper drainage moves water away without pooling or spills. When water and drainage systems work well, facilities maintain a cleaner environment that supports smooth automation and helps teams avoid hygiene-related slowdowns.

Network And Data Lines

Robotic systems rely on data connections to receive instructions, share sensor readings, and report status. Network and data lines link robots, control systems, and monitoring software. When these connections stay stable, operators can track performance and address issues quickly. Reliable data flow helps automation respond to changes and keeps cannabis production running with better visibility and control.

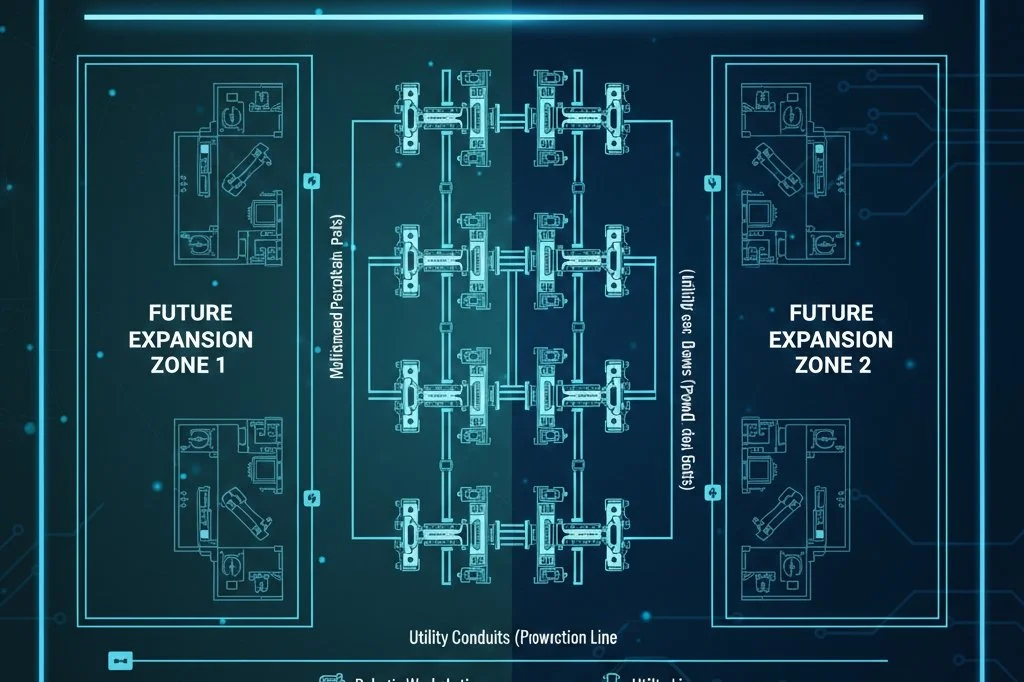

How Smart Layout Supports Cannabis Automation

The way you organize equipment, utilities, and space inside a cannabis facility influences how well automation performs. Thoughtful layout helps robots and support systems work together without bottlenecks, delays, or safety issues. Planning where machines and utilities sit before installation makes daily operations more predictable and easier for teams to manage.

Here is how layout choices keep cannabis robots working smoothly and make future upgrades easier.

Machine And Utility Alignment

Aligning machines with utility access reduces unnecessary twists in power, air, or data lines. When robotics and utilities are arranged in logical sequence, operators experience fewer process interruptions because cables and lines stay tidy and within reach. Better alignment also means teams spend less time walking between stations to troubleshoot or adjust utilities, which supports smoother production.

Power Zone Separation

Keeping high-voltage utility areas separate from sensitive processing zones makes both safer and more reliable. Heavy equipment, such as motors and converters, can generate vibration or interference that affects nearby sensors or control systems. By planning power zones away from delicate automation spaces, facilities reduce disruption and protect robotics from electrical or environmental stress.

Maintenance Access Paths

Robotics needs occasional checks, calibration, and servicing, just like other systems. Clear access paths make it easier for teams to reach equipment without shutting down entire lines. Good layout plans leave room around machines and utilities so technicians can work safely and quickly, reducing downtime and supporting long-term reliability of cannabis automation.

Future Expansion Space

Cannabis facilities that plan only for today often face challenges when they scale. Leaving extra space near key utilities and robotics cells allows teams to add new machines without major redesigns. This future-ready space also makes it simpler to reconfigure lines as workflows evolve or new automation technologies emerge.

How Proper Infrastructure Protects Quality, Compliance, And ROI

A well-prepared cannabis facility does more than keep robots running. It also protects product quality, supports regulatory expectations, and helps automation deliver real business value. When power, air, and utilities work together as a single system, production remains organized, predictable, and easier to manage across daily operations.

Here's how infrastructure supports both production needs and business priorities.

Regulatory Compliance Support

Cannabis production follows strict rules around cleanliness, safety, and environmental control. Facility systems such as airflow, electrical protection, and sanitation utilities help operations meet those standards. When infrastructure remains stable and well-organized, teams find it easier to document conditions, manage risks, and keep production areas within acceptable limits. This reduces the chance of compliance issues that can delay shipments or lead to costly corrective actions.

Reduced Downtime Risks

Unexpected shutdowns are often due to basic system failures rather than robot problems. Power drops, air issues, or utility interruptions can stop automated lines even when the machines are working correctly. Strong infrastructure lowers these risks by keeping support systems steady. Fewer interruptions mean production stays on schedule and staff spend less time responding to emergency stops or resetting equipment.

Consistent Product Quality

Cannabis products need stable conditions from handling through packaging. Infrastructure controls the environment in which robots operate, helping protect flowers, pre-rolls, and finished goods from moisture, dust, and temperature fluctuations. When machines operate inside a controlled space, each batch follows the same conditions, which supports a more uniform appearance, weight, and overall product quality.

Long-Term Automation Returns

Robotics delivers the most value when it operates with minimal disruption over the long term. Facilities that invest in strong infrastructure avoid frequent repairs, rushed upgrades, and repeated downtime. This keeps operating costs more predictable and helps automation continue to support production goals as the business grows. Over time, this stability protects the return on investment that cannabis operators expect from their automation systems.

What are the early signs that infrastructure problems are hurting cannabis automation?

Early signs include frequent machine resets, unexpected stops, unusual noise, slow production, and rising maintenance needs. These often point to unstable power, poor air control, or utility issues affecting automation.

Turn Facility Planning Into Automation Performance

When power, airflow, utilities, and layout are properly aligned, cannabis robots can finally work as intended. A well-prepared facility supports smoother production, steadier quality, and fewer interruptions, which helps automation deliver real value instead of constant troubleshooting.

Sorting Robotics designs automation systems that fit real cannabis facilities, with equipment built to operate within practical power, air, and utility conditions that support steady and controlled production environments.

If you are planning or upgrading an automated cannabis line, don't forget to explore Soring Robotics' solutions that match your facility and production goals.

Frequently Asked Questions

How do cannabis facilities know when they are ready to add robotics?

Facilities are ready when they have stable power, controlled airflow, and reliable utilities. A basic infrastructure review helps confirm whether the building can support automated systems without frequent interruptions.

What should be checked first before installing automation in an existing cannabis building?

Teams should review electrical capacity, HVAC performance, utility reliability, and available floor space. These areas determine whether robotics can operate smoothly or require facility upgrades before installation.

What types of teams should be involved when planning infrastructure for robotics projects?

Facility engineers, operations managers, compliance teams, and automation specialists should all take part. Each group helps ensure the system meets technical, safety, and production needs.

What risks come from adding robotics without upgrading utilities first?

Robots may stop often, produce errors, or require constant resets. Unstable power, poor air control, or weak utilities can reduce efficiency and raise maintenance costs.

How does infrastructure planning affect product recalls or compliance audits?

Stable facility systems support consistent conditions and better record-keeping. This makes it easier to track production, maintain quality, and respond to audits or recalls with clear data.