What Cannabis Operators Get Wrong About Scaling Too Early

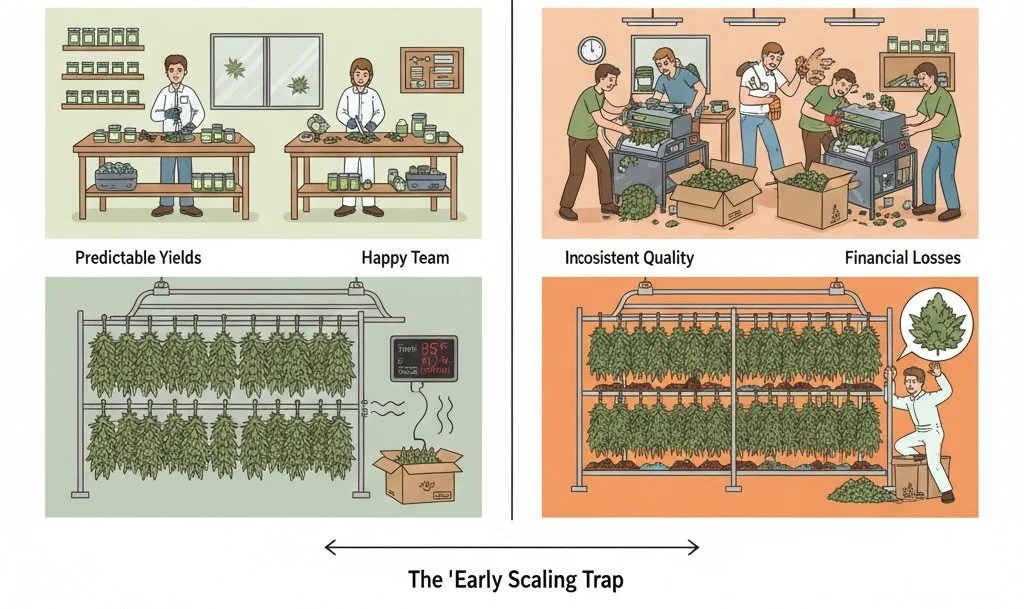

Cannabis businesses face a significant challenge when they try to scale too early. Without the right systems in place, expansion can lead to higher costs, quality issues, and increased staff stress. Many operators think bigger space and more output will fix everything, but that is not always true.

The legal cannabis market is large and growing fast. In 2024, the global legal cannabis market was valued at about $69.78 billion, and it is expected to expand significantly in the coming years, showing strong demand and growth potential for licensed producers.

This guide explains the common scaling mistakes cannabis operators make, why they happen, and how strong processes and the right tools can help make growth smoother and more predictable.

Why Cannabis Companies Feel Forced to Scale Quickly

Cannabis businesses operate in a complex environment where pressure to grow can come from many directions. The industry has expanded rapidly, and companies often feel the need to increase production and enter new markets to stay competitive and meet financial goals. At the same time, regulatory requirements and evolving rules add stress that makes cautious planning seem risky or slow.

These challenges create intense pressure for cannabis operators to grow quickly, even without stable systems in place.

Investor and Partner Growth Expectations

Outside capital can help cannabis operators grow, but investors often want to see faster returns. Bringing in money usually means expectations about revenue, market share, and business size. This can push operators to scale operations before they have reliable workflows, strong quality control, or stable processes in place.

Limited Licenses and Market Windows

Cannabis licenses are limited and governed by strict state or national rules. Operators feel pressure to secure and use these licenses quickly, as waiting could mean losing an opportunity. This creates a sense of urgency to build larger operations before the business infrastructure is stable. To meet these tight windows, many turn to robotics manufacturing services to quickly deploy specialized hardware that handles high-volume tasks.

Fear of Falling Behind Competitors

As more companies enter legalized markets, competition increases. Operators hear about others expanding and worry they will lose customers or shelf space if they do not grow too. This fear of missing out can encourage rapid scaling without careful preparation.

Early Success Can Create False Confidence

Strong early performance can make expansion look easier than it really is. A few successful harvests or sales spikes can lead operators to believe they are ready for much larger operations. Without reliable systems supporting consistency, this confidence can lead to costly problems later. . For instance, robotics manufacturing improves consistency quality by removing the human error often associated with sudden spikes in production volume.

Why does fast growth in cannabis feel right but create long-term risk?

Fast growth feels attractive because it suggests higher revenue and a stronger market position. The problem is that systems, staff, and quality controls often do not scale at the same pace. When operations grow too quickly, small gaps turn into costly issues that affect consistency, compliance, and profit.

Difference Between Cannabis Growth and Scalable Growth

Cannabis businesses often confuse growth with long-term stability. Many teams add more plants or expand space to increase output, but this step does not always improve the business. Scalable growth means operations handle higher volume while keeping control, quality, and profit intact. When teams miss this difference, expansion creates more problems than better results.

These points explain how simple growth and scalable growth lead to very different outcomes for cannabis operators.

More Plants Do Not Always Mean More Profit

Extra plants increase harvest volume, but they also raise labor, power use, and processing time. Slow trimming, sorting, or packing creates backlogs that block cash flow. Teams also risk quality loss when the product waits too long to be handled. Profit depends on smooth movement through each step, not only on plant count. To protect these margins, operators should increase profit margins infused pre-rolls by focusing on high-value, efficiently produced goods.

Fast Expansion Can Hurt Quality and Consistency

Rapid growth stretches teams and systems beyond safe limits. Staff rush to meet volume demands, and small details get missed during handling and sorting. These mistakes create uneven quality across batches. Buyers notice these changes quickly. Consistent quality builds trust with distributors and customers, which protects long-term revenue.

Many cannabis grow operations struggle after they expand

Expansion adds more rooms, plants, and daily tasks. Processes that worked at a smaller size often break under higher volume. Tasks take longer, and teams lose track of issues. Errors increase and raise operating costs. Weak systems turn growth into stress and financial pressure.

Scalable Growth in Cannabis Operations

Scalable growth allows every part of the operation to handle more volume without chaos. Teams keep the same clear workflows as output rises. Quality checks stay consistent, and managers track data without confusion. Operators can accept larger orders, meet delivery dates, and protect product value as the business grows.

Stable Systems Support Long-Term Business Growth

Strong systems provide a business with a solid foundation for expansion. Clear workflows and accurate data reduce waste and mistakes. Teams spend less time fixing problems and more time producing quality products. This structure also makes it easier to add tools and automation that improve speed and accuracy, which keeps growth steady and controlled.

Most Common Mistakes Cannabis Operators Make When Scaling Early

Many cannabis businesses do not fail because they grow. They struggle because they grow without fixing the things that already slow them down. When operators push for higher output before building a strong base, small weaknesses begin to show. These mistakes may look minor at first, but they can quickly affect costs, quality, and daily operations as the business expands.

These are some of the most common issues that appear when cannabis companies try to scale too early.

Space Over Process Control

Some operators focus on adding more grow rooms or more square footage, but they leave their daily workflows unchanged. Larger facilities only magnify weak processes. Teams move product through more space, which increases delays and confusion. Without clear steps for handling, sorting, and moving cannabis, bigger operations become more complex to manage and more expensive to run.

More Staff More Waste

Hiring more workers is a quick fix for higher volume. In reality, more people without better systems often create more mistakes. Different workers may handle plants or products differently, leading to uneven results. Training also takes time and money. When teams rely only on extra labor, waste and rework start to rise.

No Data No Predictability

Growth without precise data leaves operators guessing. Without tracking yields, processing times, or losses, teams cannot plan how much they can handle. This makes it hard to accept new orders with confidence. Sudden spikes in volume then create stress, missed deadlines, and unhappy buyers because the operation has no reliable way to predict output.

Quality and Compliance Risks

Early scaling can push teams to rush through important checks. This raises the risk of uneven grading, packaging errors, or missed compliance steps. In cannabis, quality and rule adherence matter for every batch. When operators move too fast, these risks grow and can lead to rejected product, lost trust, or regulatory trouble. Relying on robotics integration services ensures that compliance and safety are built directly into the automated production line.

How Small Inefficiencies Turn Into Big Losses When You Scale

Small issues often stay hidden when a cannabis operation runs at a lower volume. Once output increases, those same issues begin to show up in daily work. Extra minutes, small mistakes, and slow handoffs all start to stack up. Over time, they raise costs, slow down teams, and reduce the amount of product that reaches the market in good condition.

These common problem areas show how minor gaps can grow into serious business challenges.

Trimming Delays Adds Costs

When trimming takes longer than expected, harvested plants start to pile up. Fresh cannabis loses value when it sits too long before proper handling. Staff then feel pressure to rush, which can lead to uneven work. Delays also push back packaging and shipping, tying up cash and making it harder to meet delivery schedules.

Sorting Errors Reduce Quality

Manual sorting leaves room for mistakes, especially as volume increases. Mixed grades or missed defects can move through the system unnoticed. Buyers may receive a product that does not match their expectations, which hurts trust. Over time, these quality slips can lead to more complaints, returns, and strained business relationships.

Rework and Batch Rejections

Mistakes during processing often require teams to redo work. This adds labor time and wastes materials. In some cases, whole batches fail to meet buyer or regulatory standards and must be pulled from sale. These losses do not always show up right away, but they slowly reduce overall output and raise operating costs.

Profit Margins Shrink

Every extra step, delay, or correction adds expense. Labor, energy, and packaging costs grow while usable product stays the same or even drops. As a result, the profit per unit sold begins to decline. Even strong sales cannot make up for this kind of hidden revenue drain.

Volume Multiplies Problems

As production grows, minor weaknesses turn into significant obstacles. A process that feels manageable at low scale becomes a bottleneck at higher volume. More product moving through the same gaps increases the risk of errors, waste, and delays. Without tighter systems, growth makes operations harder to control instead of more efficient.

How can cannabis operators identify hidden inefficiencies before they affect large production volumes?

Operators can review workflow timing, error rates, rework levels, and product delays to spot small issues early, before increased volume turns them into higher-cost, higher-quality problems.

Why Labor-Based Scaling Struggles in Cannabis Operations

Cannabis businesses often depend on people to handle trimming, sorting, and packing as they grow. This works at a small scale, but at higher volumes it puts more pressure on every worker. As output increases, teams face more stress, more steps, and tighter deadlines. Over time, this makes it harder to maintain quality and keep costs under control.

Here's how labor-intensive growth becomes harder to manage as cannabis operations expand.

High Turnover Training Gaps

Cannabis facilities often see workers come and go. Each new hire needs time to learn how to handle, grade, and follow safety rules. During training periods, experienced staff must slow down to help, which reduces overall output. Mistakes also become more common when people do not fully understand the process. This makes steady production harder to maintain.

Fatigue Reduces Consistency

Long hours and repetitive tasks wear people down. When workers feel tired, they may miss small details or rush through steps. In cannabis processing, small differences in trimming or sorting can affect how the final product looks and feels. Fatigue leads to uneven results, even when teams try their best.

Compliance Risks Increase

Cannabis rules require careful tracking, clean handling, and accurate labeling. As more people touch the product, the chance of a missed step grows. A skipped record or a labeling error can create problems during inspections or with buyers. These risks rise when teams rush to keep up with higher volume.

Cost Per Gram Rises

Labor makes up a large share of processing costs. When a business hires more workers to handle growth, wages, benefits, and training expenses increase. If output does not rise at the same pace, the cost for each gram of product goes up. This reduces profit, even when sales look strong.

Systems Outscale People

People can only work so fast and for so many hours. Systems, on the other hand, can repeat a task at a steady pace and with consistent accuracy. As volumes grow, businesses need methods that remain reliable without added strain. This is why many cannabis operators look for better ways to support their teams with more consistent tools.

How Modern Cannabis Operations Prepare for Automation

Cannabis companies that plan for automation focus on building order into daily work before they bring in new tools. They look at how products move through the facility, how teams complete tasks, and where delays or mistakes happen. When these basics stay clear and organized, technology can support growth rather than create more confusion.

The cannabis technology market is growing rapidly, with an estimated value of about $5.15 billion in 2025 and projected to reach over $25 billion by 2032, showing strong investment in tools that support cultivation, processing, and automation.

Here's how well-prepared operations set themselves up for smoother, more reliable expansion.

Standardized Daily Workflows

Clear steps guide workers in handling plants, sorting flowers, and packaging products. Everyone follows the same process from start to finish. This reduces guesswork and keeps work moving in a steady way. When teams follow shared routines, new tools can fit into the process without causing disruption.

Predictable Production Output

Well-run facilities know how much product they can process in a day or a week. This helps them plan staff schedules, delivery dates, and inventory. When output remains predictable, operators can confidently decide when to add more capacity rather than react to constant surprises.

Data Guides Decisions

Strong operations track key numbers such as yield, processing time, and waste. Managers use this information to spot problems early and adjust plans. Data replaces guesswork and provides a clearer picture of where improvements can have the greatest impact.

Consistent Product Quality

Customers expect the same look, feel, and grade every time they order. Automation-ready facilities focus on repeatable handling and sorting methods. This keeps quality steady across batches and helps protect relationships with buyers.

Simple Capacity Expansion

When workflows stay organized, adding more volume becomes easier. Teams can plug in new equipment or extend work hours without changing the entire operation. This allows businesses to grow steadily while maintaining control over costs and performance.

How can a cannabis facility tell when it is genuinely ready to introduce automation?

A cannabis facility is ready for automation when workflows stay consistent, production remains predictable, and teams can clearly track output, errors, and delays without relying on guesswork or manual estimates.

Grow Your Cannabis Business Without Risk

Scaling cannabis production should not mean more chaos, more rework, or rising labor costs. The most successful operators grow by strengthening their systems first, especially in high-impact areas like sorting, coating, and infusion.

Sorting Robotics helps cannabis teams scale with automation designed for real production challenges. Solutions like Stardust for consistent kief coating and Jiko and Jiko+ for precise pre-roll infusion help remove bottlenecks that slow teams down as volume increases. These systems support steady output, repeatable quality, and predictable processing without adding unnecessary labor.

If your operation is feeling the pressure of growth but your processes are struggling to keep up, explore how Sorting Robotics can help you scale with control, clarity, and confidence.

Frequently Asked Questions

What early signs show that manual processing is no longer sustainable?

Rising rework, growing backlogs, missed delivery dates, inconsistent quality, and increasing labor hours per batch show that manual processes can no longer support higher production volumes.

What parts of cannabis processing benefit most from automation first?

Sorting, grading, and packaging benefit first because these steps require consistency, speed, and accuracy, and they directly affect product quality, buyer satisfaction, and overall processing efficiency.

How can cannabis businesses estimate their actual processing capacity?

Businesses can track how much product moves through each step per shift, measure delays and errors, and compare planned output to actual results to understand real processing limits.

How can cannabis operators protect product quality while scaling?

Clear handling rules, consistent grading methods, proper tracking, and controlled processing speeds help cannabis operators maintain stable quality as production volume increases across multiple harvests and customer orders.

What should cannabis operators review before investing in new technology?

Operators should review workflow stability, data accuracy, processing bottlenecks, labor costs, and growth plans to ensure that new technology aligns with current needs and supports future expansion without disruption.