Why Throughput per Square Foot Matters More Than Speed in Cannabis Facilities

Machine speed is frequently the primary selling point for cannabis automation equipment. Manufacturers promise thousands of units per hour, yet production facilities often fail to see a corresponding rise in finished goods. The disconnect lies in a fundamental misunderstanding of efficiency.

Profitability in cannabis manufacturing is not driven by raw speed, but by throughput per square foot. This metric measures the volume of finished product a facility produces relative to its total footprint. With U.S. legal cannabis revenue projected to reach around $36.8 billion in 2026, production facilities face intense pressure to maximize every inch of space to achieve efficient output and protect margins.

In an industry where facility space is a fixed, expensive asset and regulatory constraints limit expansion, maximizing output per available square foot is the only reliable path to scaling operations. A robotics integration roadmap allows owners to plan for this density from the start.

This article explains why throughput per square foot outweighs machine speed as a KPI and outlines how to optimize it to achieve higher margins.

Why Chasing Machine Speed Alone Can Backfire

The reality is that operators frequently prioritize "units per hour" specs without calculating workflow integration. A machine rated for 1,500 pre-rolls per hour provides zero value if the surrounding processes cannot support that velocity.

Speed without alignment creates immediate bottlenecks. If grinding, packing, or labeling stations cannot keep pace with a high-speed infusion machine, the asset becomes a liability rather than a productivity booster.

For example, a facility that uses a high-speed infusion system while relying on manual packaging downstream experiences an immediate operational failure. The automated system produces products faster than the manual team can pack, resulting in work-in-progress (WIP) inventory piling up on the floor. This inventory consumes valuable space and generates no revenue until it leaves the facility.

Speed is irrelevant when the overall workflow lacks the capacity to process it. This issue is pervasive in the sector; according to the Siemens True Cost of Downtime 2024 report, unplanned downtime and operational inefficiencies now consume approximately 11% of annual revenue for major manufacturers, underscoring the critical need for balanced workflows. Choosing the best pick and pack robot can help balance these downstream bottlenecks.

Does purchasing high-speed equipment require immediate facility upgrades?

Often, yes. Industrial-scale speed requires industrial-scale infrastructure. High-velocity machines frequently demand upgraded electrical capacity, compressed air systems, and HVAC capabilities to handle the increased heat load. Ignoring these hidden infrastructure costs can lead to expensive retrofits or equipment that cannot run at its rated capacity due to facility limitations.

What Throughput per Square Foot Actually Measures

Throughput per square foot is defined as the total units of finished goods produced divided by the total floor space dedicated to production. While speed is a measure of machine capability, throughput per square foot is a measure of facility-wide operational efficiency.

This metric is critical due to the high cost of infrastructure. According to industry reporting from MMJDaily, startup costs for indoor cultivation facilities typically range between $325 and $650 per square foot, depending on complexity and region. Additionally, state regulations typically prevent shipping products across borders, meaning each licensed facility must maximize its specific footprint to remain competitive.

Current legal frameworks create what Vanderbilt Law School describes as "hermetically sealed" markets, preventing cross-border efficiency gains and forcing operators to optimize within strict geographical boundaries. Implementing custom robotics integration services is often the most effective way to squeeze more value out of a constrained footprint.

The formula provides a clear efficiency baseline:

(Total Units Produced) ÷ (Production Floor Space in Sq Ft) = Throughput per Square Foot.

Consider this comparison to illustrate the difference. Facility A operates a 5,000 sq ft floor producing 100,000 pre-rolls per month, resulting in 20 units per sq ft. Facility B operates a 3,000 sq ft floor producing 90,000 pre-rolls per month, resulting in 30 units per sq ft. Facility B demonstrates superior operational efficiency and higher revenue potential per dollar of fixed assets.

Should non-production areas, such as hallways, be included in the calculation?

No. To get an accurate measure of production efficiency, isolate the square footage of the actual manufacturing floor, including staging and active storage areas. Including administrative offices, hallways, or break rooms dilutes the metric and obscures the true efficiency of your revenue-generating space.

Common Reasons Cannabis Facilities Underperform on Throughput per Square Foot

Inefficiency usually stems from specific structural and operational bottlenecks common in the industry. This aligns with market research indicating that processing and manufacturing facilities are increasingly relying on automation to reduce manual labor costs and minimize human error, a critical trend driving the projected growth of the cannabis technology market.

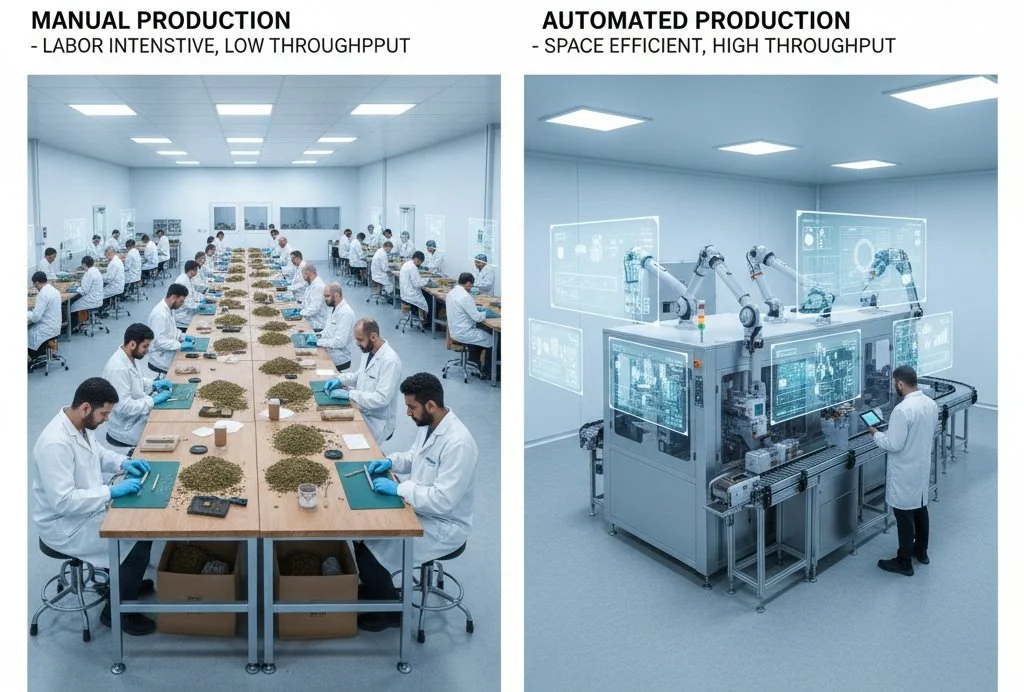

Labor-Intensive Processes Consume Floor Space

Manual workflows are inherently space-inefficient. Tasks such as hand-rolling, operating knock boxes, and manual coating require large workstations to accommodate multiple employees. A team of 10 workers requires significantly more square footage than a single automated system, limiting the room's production capacity. Implementing cannabis automation ROI and pilot planning can help visualize how much space is recovered when shifting away from manual labor.

Equipment Footprint Mismatches Dilute Efficiency

Legacy automation equipment often suffers from poor design optimization. Machines that occupy substantial floor space without delivering proportional output dilute the facility's efficiency ratio. Equipment must be evaluated based on output density, which measures production volume relative to the physical space it consumes.

Workflow Gaps Create Unprofitable Transit Zones

Inefficient facility layouts force materials to travel excessive distances between grinding, infusion, and packaging stations. Transit zones and hallways do not generate revenue. A layout that fails to minimize material movement wastes valuable square footage that could otherwise be used for production.

Underutilized Vertical Space Limits Capacity

Facilities often ignore verticality, optimizing only for horizontal floor space. Conveyor systems and vertical storage solutions allow operators to stack processes, effectively multiplying the facility's usable area. Neglecting vertical space limits potential throughput density.

Compliance and Safety Buffer Zones Reduce Usable Area

Regulatory requirements mandate aisle clearances and emergency access routes. While necessary, these buffer zones reduce usable production space. Efficient facility planning accounts for these constraints upfront, ensuring compliance without sacrificing production capacity. Once these inefficiencies are identified, the most effective lever for reclaiming that space is strategic automation.

How does material flow direction impact square footage usage?

Linear layouts often create long, unused return paths for staff and materials. U-shaped or cellular layouts typically use space more efficiently by minimizing transit distances and allowing input and output stations to share resources. A layout that forces the product to travel across the entire facility and back wastes valuable footage on transit rather than value creation.

The Role of Automation in Maximizing Production Density

Strategic automation does more than increase speed; it fundamentally alters the math of production density.

Compact Machines Maximize Output Density

Advanced automation systems are engineered to maximize throughput while minimizing footprint. The Jiko system, for instance, infuses up to 1,000 joints per hour while occupying a fraction of the space required for a manual infusion line. This allows facilities to increase output without expanding their physical footprint.

Single-Operator Stations Consolidate Labor Requirements

Automation consolidates labor requirements. Where manual infusion requires teams spread across multiple tables, automated solutions like Jiko allow a single operator to manage the entire process. This reduction in personnel clears floor space for additional equipment or alternative production lines.

Faster Changeovers Minimize Dead Space

Equipment capable of handling multiple SKU formats eliminates the need for redundant machinery. A single system that processes cones, tubes, and blunts removes the need for separate lines for each product type. This versatility directly translates to a smaller machinery footprint.

Consistent Production Reduces Buffer Storage Needs

Automated consistency reduces the need for large staging areas. Predictable production flow minimizes WIP inventory, allowing facilities to reclaim space previously dedicated to storing unfinished product. Materials move continuously through the line rather than being stored.

Integration Tightens the Entire Production Line

Synchronizing infusion, coating, and packaging tightens the entire production line. When machines communicate and hand off products seamlessly, the physical distance between stations can be reduced. This integration eliminates the need for manual transfer tables, creating a denser, more efficient production floor.

The contrast is stark. In a manual operation, 800 sq ft might be dedicated to a team producing 10,000 units per shift. An automated Stardust system (rated for up to 1,500 units per hour) can match that output in under 100 sq ft. That is 700 sq ft of reclaimed capacity available for revenue-generating activities.

Does compact automation compromise maintenance accessibility?

It can if not properly designed. Well-engineered compact systems, like those from Sorting Robotics, prioritize modularity. Key components should be accessible from the front or sides without requiring the machine to be moved. If a machine requires three feet of clearance on all sides for maintenance, its effective footprint is significantly larger than its physical dimensions.

Key Factors When Selecting Automation Equipment

To maximize ROI on floor space, operators must evaluate automation systems against specific density criteria:

Footprint vs. Output Ratio: Do not rely on the "units per hour" spec alone. Divide the machine's rated output by its physical dimensions to determine its density score. A system producing 1,000 units per hour is inefficient if it monopolizes 500 sq ft of floor space.

Seamless Integration Capabilities: Prioritize systems that physically and digitally connect with upstream and downstream processes. The goal is to eliminate manual handoffs, which invariably require additional space for tables, carts, and personnel.

Minimal Operator Requirements: Verify the machine is rated for single-operator use. Every additional human operator required adds exponentially to the space needed for personal clearance and safety compliance.

SKU Flexibility Without Additional Hardware: Look for systems that adapt to various product formats via software settings or simple adjustments rather than requiring bulky hardware modules. "All-in-one" capabilities prevent the proliferation of single-use machines.

Real-Time Tracking for Layout Optimization: Ensure the equipment provides granular data visibility. Production dashboards help identify exactly where the flow slows, allowing operators to adjust the floor plan for maximum throughput without incurring capital expenditure.

Is Custom-Built Automation Necessary to Achieve Maximum Density?

Rarely. While custom solutions seem tailored to a space, they often lack the modularity and field-tested reliability of standard platforms. Modular standard equipment is typically engineered for broad compatibility and density, whereas custom "one-off" machines often end up with bloated footprints due to a lack of iterative design refinement.

How to Track and Improve Throughput per Square Foot

Optimizing this metric requires a disciplined approach to measurement and iterative improvement.

Step 1: Calculate Your Current Baseline

Determine the facility's current efficiency by dividing total monthly unit output by the total square footage dedicated to production, including all handling and staging zones.

Step 2: Identify Your Biggest Space Consumers

Conduct a facility audit to identify low-density areas. Locate clusters of manual labor, large WIP storage zones, and equipment with poor output-to-size ratios.

Step 3: Set a Realistic Target Benchmark

Establish benchmarks based on competitive standards. Efficient infused pre-roll facilities typically achieve 25-35 units per sq ft per shift. Optimized operations utilizing advanced automation can exceed 50 units.

Step 4: Prioritize High-Impact Automation Changes

Direct automation investment toward process steps with the highest labor concentration and lowest throughput density. Infusion and coating are frequently the most effective targets for immediate improvement.

Step 5: Re-Measure Efficiency Monthly

Monitor throughput per square foot as a primary KPI. Continuous measurement ensures that process changes translate into tangible efficiency gains.

What is the typical ROI timeline for layout optimization projects?

Operational changes, such as moving manual workstations or reducing buffer zones, can yield immediate results with near-zero cost. Automation investments typically target an ROI of 6 to 12 months. However, the throughput gains from optimization often compound, meaning the profitability impact accelerates the longer the improved system runs.

Throughput per Square Foot Is the Metric That Matters

Machine speed provides incomplete data. Throughput per square foot offers a comprehensive view of production efficiency. Automation serves as the primary mechanism for improving this metric, provided the equipment, such as Jiko, Jiko+, and Stardust, is engineered for space efficiency.

Cannabis manufacturers aiming for long-term viability must shift focus from equipment velocity to facility-wide throughput density. Facilities that master this metric position themselves to lead the market as competition intensifies.

Sorting Robotics provides the automation infrastructure required to maximize this metric. Book a demo to evaluate how Jiko and Stardust systems increase production density while maintaining craft-level quality.

Frequently Asked Questions

What is a competitive throughput-per-square-foot benchmark for infused pre-rolls?

Competitive facilities typically achieve 25-35 infused pre-rolls per square foot per shift. Operations optimized with high-density automation can exceed 50 units per square foot.

Does automation automatically improve throughput per square foot?

No. Improvement depends on the specific design of the equipment. Large, inefficient machines can reduce throughput density. Automation must be compact and integrated to deliver a positive ROI on space.

How is throughput per square foot calculated?

Divide the total monthly unit output by the total floor space dedicated to production, including all staging and handling areas. This metric should be tracked monthly.

Can throughput per square foot be improved without new equipment?

Workflow reorganization, reduction of staging areas, and optimization of material handling can yield improvements. However, automation typically delivers the most significant increases in production density.