From Handcrafted to Industrial: Managing Brand Perception During Automation

Scale without compromise defines the modern cannabis landscape. Brands relying on manual labor face a critical reality: demand is scaling faster than human hands can manage. With 80.5% of operators planning to leverage technology to streamline processes, according to SilverLeaf's State of the Industry Report, the decision is no longer "if" but "how." Industry leaders are transitioning from boutique workshops to precision manufacturing without sacrificing their identity.

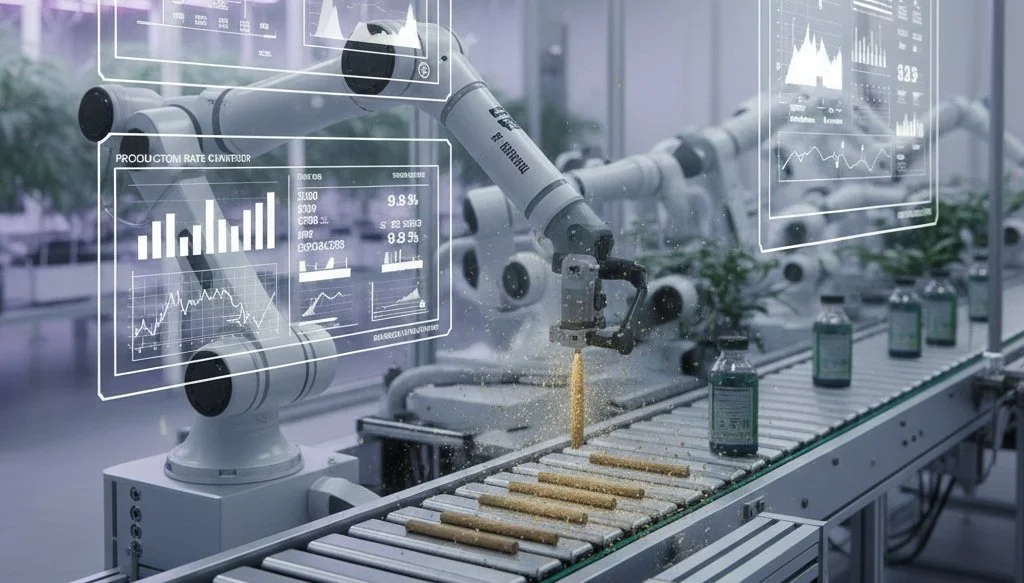

Precision automation does not dilute craftsmanship; it secures it. Manual production introduces variability through fatigue, leading to inconsistent weights and wasted material. Purpose-built automation delivers the exact same specification every cycle, especially when implementing a seamless integration of Jiko Stardust Omni into existing facilities.

In this article, we examine how to scale production throughput while maintaining the rigorous quality standards that consumers demand.

The Perception Problem Cannabis Brands Face

Overcoming consumer hesitation requires understanding the root of their skepticism regarding automated production.

The Legacy of Agricultural Adaptation

The stigma surrounding automation in cannabis stems from a specific historical context. Early industry automation was often repurposed equipment from the tobacco or agriculture sectors.

These machines prioritized speed over product integrity, often crushing trichomes, compromising bag appeal, and homogenizing unique cultivars into generic biomass. This legacy created a lingering consumer association between "machine-processed" and "low quality."

However, this perception is outdated as the modern manufacturing floor looks entirely different. The parallel with the craft beer industry is instructive. Breweries scaled from garage operations to industrial facilities by leveraging technology to improve product consistency.

Precision temperature control and automated bottling did not destroy the craft but instead ensured that the consumer experience remained identical across thousands of units. Cannabis is undergoing the same maturation, where brand authenticity is defined not by manual labor but by genetic quality, curing standards, and reliable consumer experiences.

Addressing the Consistency Gap

A premium brand requires premium consistency because if consumer experience varies due to manual inconsistencies, the "craft" designation loses value. Automation provides the only viable path to guarantee product uniformity at scale. Brands must recognize that maintaining artisanal positioning while shipping high volumes requires scaling cannabis business robotic packaging to meet market demand without losing quality.

Does automation inevitably compromise the "craft" designation?

Craft is defined by the quality of the end product rather than the absence of tools. If a machine preserves trichome integrity better than a human hand, the craft integrity actually increases. The designation relies on the care put into the input material and the curing process, both of which are preserved in this model.

The Market Reality Forcing the Decision

Staying competitive requires adapting to the financial and operational realities currently reshaping the industry.

Economic Pressures Driving Automation Adoption

Market dynamics are forcing a shift in operational strategy. According to Coherent Market Insights, the cannabis technology sector is projected to grow from $5.15 billion in 2025 to over $25.41 billion by 2032, driven largely by the need for operational efficiency. Competitors are heavily investing in this infrastructure to combat margin compression.

Labor costs continue to compress margins, making reliance on manual teams for repetitive tasks financially inefficient. Operators cannot afford to deploy human capital to processes that machines execute faster and with lower error rates. Automation significantly reduces labor costs while stabilizing production schedules.

The Explosion of the Infused Segment

The pre-roll market serves as the primary indicator of this trend. Data from Headset reveals that "Connoisseur / Infused" pre-rolls now capture approximately 42.3% of total pre-roll sales in the US market. Producing consistent, manually infused products at scale is operationally unfeasible, leading to uneven injection, wasted concentrate, and slow throughput. Brands attempting to compete in this high-margin category without automation will face insurmountable efficiency disadvantages compared to competitors that automate.

Is automation viable for smaller operational footprints?

Scalability protects margins regardless of company size. Even small operators face price compression and market volatility. Automation stabilizes operational costs, allowing smaller brands to compete on shelf price while maintaining healthy margins that manual labor would erode.

The Hybrid Manufacturing Model for Craft Cannabis

Balancing efficiency with artistry requires a production framework that leverages the strengths of both humans and machines.

Strategic Deployment of Human Capital

The most effective approach is the hybrid manufacturing model, which combines high-throughput automation with strategic human oversight to create a "small batch at scale" production philosophy. Industry analysis from mg Magazine emphasizes that successful scaling requires automating for agility rather than austerity. This shift eliminates repetitive tasks and enables staff to transition into revenue-driving roles such as quality control, R&D support, and inventory management.

Operators must audit their production lines to identify tasks suitable for automation, such as weighing and filling. A machine achieves 0.01g accuracy consistently, whereas human accuracy drifts over a shift. Infusion and packaging also benefit from the repeatability of robotics, allowing human expertise to be reallocated to high-value areas.

Focusing on Quality-Critical Touchpoints

Final quality inspection, curing oversight, strain selection, and product development remain deeply human processes. This division of labor ensures that the product's soul remains intact while the mechanical execution is perfected.

Equipment selection is critical here. Technologies like the Jiko infusion system allow for the injection of concentrates with 0.05g accuracy directly into the center of a pre-roll. This mimics the care of a hand-rolled donut joint but executes it at industrial speeds, serving as a clear example of technology enabling a product format that would be inconsistent if produced by hand.

Does the hybrid model require custom machinery?

Off-the-shelf industrial food equipment rarely suits cannabis due to the unique physical properties of the plant. Purpose-built technology ensures the machine adapts to the resinous nature of cannabis, preventing the product degradation common with generic agricultural equipment.

Reframing the Automation Narrative for Customers

How brands discuss their technology determines whether customers perceive it as a compromise or an enhancement.

Communicating Precision as a Value Proposition

Brands often hesitate to disclose their use of automation, but this secrecy is a strategic error because transparency establishes trust. The narrative must shift from "avoiding machines" to "utilizing precision engineering." Marketing communications should emphasize that robotics manufacturing improves consistency quality, ensuring every customer receives the exact same premium experience.

Marketing communications should emphasize the benefits of this technology:

Precision-Engineered rather than "automated."

Consistent Craft Quality rather than "mass-produced."

Master-Crafted with Technology rather than "machine-made."

Transparency as a Competitive Asset

Consumers prioritize outcomes and demand a consistent burn, accurate dosing, and a reliable effect. Automation is the tool that guarantees these outcomes. Brands should showcase their investment in technology as a commitment to quality control, using data from automated systems to prove that every batch meets strict weight and potency standards. This creates a narrative where technology is the guardian of quality rather than its enemy.

How should brands respond to direct inquiries about "hand-rolled" claims?

Pivot the conversation to accuracy and reliability. Acknowledge the technology used to ensure a perfect burn and consistent weight. Frame the automation as a quality assurance measure that guarantees the customer receives the exact experience they paid for, every single time.

Where Precision Automation Creates Premium Value

Beyond operational efficiency, advanced robotics provides tangible opportunities to increase product value and profitability.

Driving Margins via Infused Product Consistency

Strategic automation directly impacts the bottom line. As reported by MJBizDaily, U.S. pre-roll sales jumped nearly 12% year-over-year, while 40% of new products released in Canada were pre-rolls. This shift toward ready-to-consume formats allows brands to realize significant gross margin increases.

However, capturing this value requires automation to prevent waste and ensure sellable inventory, especially as top-selling SKUs are increasingly infused.

Kief Coating and Visual Appeal

Advanced robotics also enables premium product differentiation. Automated systems like the Stardust can apply a uniform layer of kief to thousands of joints per hour. Attempting this process manually is wasteful and yields inconsistent visual results, whereas a precisely applied machine coating signals premium quality on the shelf and commands a higher price point.

Data-Driven Quality Assurance

Consistency is a premium proof point. Automated systems generate granular production data that manual processes cannot match. This data supports GMP compliance and provides dispensaries with assurance of product reliability. As federal regulations loom, facilities operating with documented, automated processes will hold a distinct advantage over those relying on undocumented manual labor.

How to Plan a Smooth Transition to Automated Production

Moving from manual processes to automated systems requires careful planning to minimize disruption and maximize ROI.

Operational Transition Strategy

Transitioning to an automated floor requires a calculated approach. Operators should avoid complete facility overhauls in favor of targeted problem-solving. Identifying the single largest bottleneck, whether weighing, twisting, or infusion, provides the starting point.

Selecting equipment partners with specific cannabis expertise is vital because the machinery must be designed to handle the resinous, variable nature of the plant. Generic industrial equipment will fail to deliver the necessary gentle handling.

Workforce Evolution

Communication with the workforce is equally important, as automation should be positioned as an upgrade to their roles. Staff members transition from repetitive manual labor to skilled machine operation and quality control, thereby improving employee retention and upskilling the workforce for a modern manufacturing environment.

How does automation handle high-SKU variety?

Modern systems are designed for quick changeovers, allowing brands to rotate strains without significant downtime. This flexibility ensures that craft producers can maintain a diverse menu while still benefiting from the speed and consistency of automated production.

Craft Quality at Scale is the New Competitive Requirement

The dichotomy between "craft" and "scale" is false because the market demands both. The next generation of category leaders will be defined by their ability to use precision technology to deliver artisanal quality at volume.

Consistency drives brand loyalty, and retail partners and consumers alike reward reliability. Smart automation provides the infrastructure to deliver that reliability without inflating costs. Operators must choose between clinging to inefficient manual legacies or evolving into precision manufacturers.

Sorting Robotics provides the engineering solutions required for this evolution. We design robots specifically for cannabis operators who refuse to compromise on quality. To discuss how precision automation can resolve production bottlenecks and elevate brand positioning, book a consultation with our engineering team today.

Frequently Asked Questions

How does automation impact regulatory compliance?

Automated systems eliminate human variability and error, which drastically improves adherence to state regulations. Machines provide precise weight data and production logs for every unit, creating an undeniable audit trail that simplifies reporting and GMP certification.

Can automation be implemented in phases?

Phased implementation is often the most strategic approach for growing operators. Brands can automate specific high-pain points like weighing or filling first, then integrate downstream packaging solutions later. This protects cash flow and allows the workforce to adapt gradually.

How does automation improve product shelf life?

Automated packaging systems, particularly those using nitrogen flush technology or airtight sealing, significantly extend product freshness. By minimizing human handling and exposure to oxygen during the filling process, operators preserve terpene profiles and potency for longer periods.

What are the maintenance requirements for automated systems?

Modern cannabis robotics are designed for user-friendly maintenance but require regular preventive care. Routine tasks like sensor cleaning and calibration are typically handled by trained internal staff, while complex technical servicing is supported by the manufacturer.

How does AI enhance cannabis manufacturing?

AI integration allows for real-time predictive analytics that human operators cannot replicate. Advanced systems analyze input variability to adjust machine settings on the fly, ensuring consistent output quality even when the physical properties of the flower batch change.